Processing technique for spicy bean puffer

A processing technology, a technology for spicy bean curd, applied in the field of fugu processing technology of spicy bean curd, can solve the problems of wasting puffer fish resources and not fully utilized, etc., and achieves the effects of food safety, easy portability and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

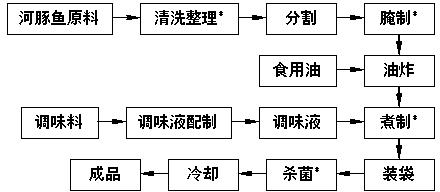

[0019] like figure 1 Shown, a kind of spicy watercress pufferfish processing technology comprises the steps:

[0020] (1) Cleaning and finishing: peel off the fish skin, remove the viscera, remove the peritoneal lining, place the cod liver etc. separately, and clean the puffer fish in running water. It is the tendons, membranes and internal organs, etc. After cleaning, it will be inspected by a special person;

[0021] (2) Segmentation: Remove the head of the puffer fish, slice it into two pieces along the back, and cut it into 25 mm square pieces;

[0022] (3), marinated at low temperature: first add green onion, ginger, and cooking wine to the fish pieces and mix well. The ratio of fish pieces to green onions, ginger, and cooking wine is about 25:2:1:1; the ratio of fish pieces to edible salt is 110:1 Stir in the proportion of the mixture, put it in a container and marinate at 3°C, and the marinating time is 60 minutes;

[0023] (4) Frying: Put the marinated fish pieces i...

Embodiment 2

[0029] like figure 1 Shown, a kind of spicy watercress pufferfish processing technology comprises the steps:

[0030] (1) Cleaning and finishing: peel off the fish skin, remove the viscera, remove the peritoneal lining, place the cod liver etc. separately, and clean the puffer fish in running water. It is the tendons, membranes and internal organs, etc. After cleaning, it will be inspected by a special person;

[0031] (2) Segmentation: Remove the head of the puffer fish, slice it into two pieces along the back, and cut it into 25 mm square pieces;

[0032] (3), marinated at low temperature: first add green onion, ginger, and cooking wine to the fish pieces and mix well. The ratio of fish pieces to green onions, ginger, and cooking wine is about 25:2:1:1; the ratio of fish pieces to edible salt is 110:1 Stir in the proportion of the mixture, put it in a container for pickling at 5°C, and the pickling time is 60 minutes;

[0033] (4) Frying: Put the marinated fish pieces int...

Embodiment 3

[0039] like figure 1 Shown, a kind of spicy watercress pufferfish processing technology comprises the steps:

[0040] (1) Cleaning and finishing: peel off the fish skin, remove the viscera, remove the peritoneal lining, place the cod liver etc. separately, and clean the puffer fish in running water. It is the tendons, membranes and internal organs, etc. After cleaning, it will be inspected by a special person;

[0041] (2) Segmentation: Remove the head of the puffer fish, slice it into two pieces along the back, and cut it into 25mm square pieces;

[0042] (3), marinated at low temperature: first add green onion, ginger, and cooking wine to the fish pieces and mix well. The ratio of fish pieces to green onions, ginger, and cooking wine is about 25:2:1:1; the ratio of fish pieces to edible salt is 110:1 Stir in the proportion of the mixture, put it in a container and marinate at 4°C, and the marinating time is 60 minutes;

[0043] (4) Frying: Put the marinated fish pieces in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com