Adjustable flat plate stirring tooth component for granulator

A technology of leveling plate and granulator, which is applied in the direction of granulation in static tanks/slots, etc., can solve the problem of not reaching the service life of the stirring teeth for convenient maintenance, and achieve convenient maintenance and operation of the stirring teeth, prolong the service life, and reduce maintenance. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

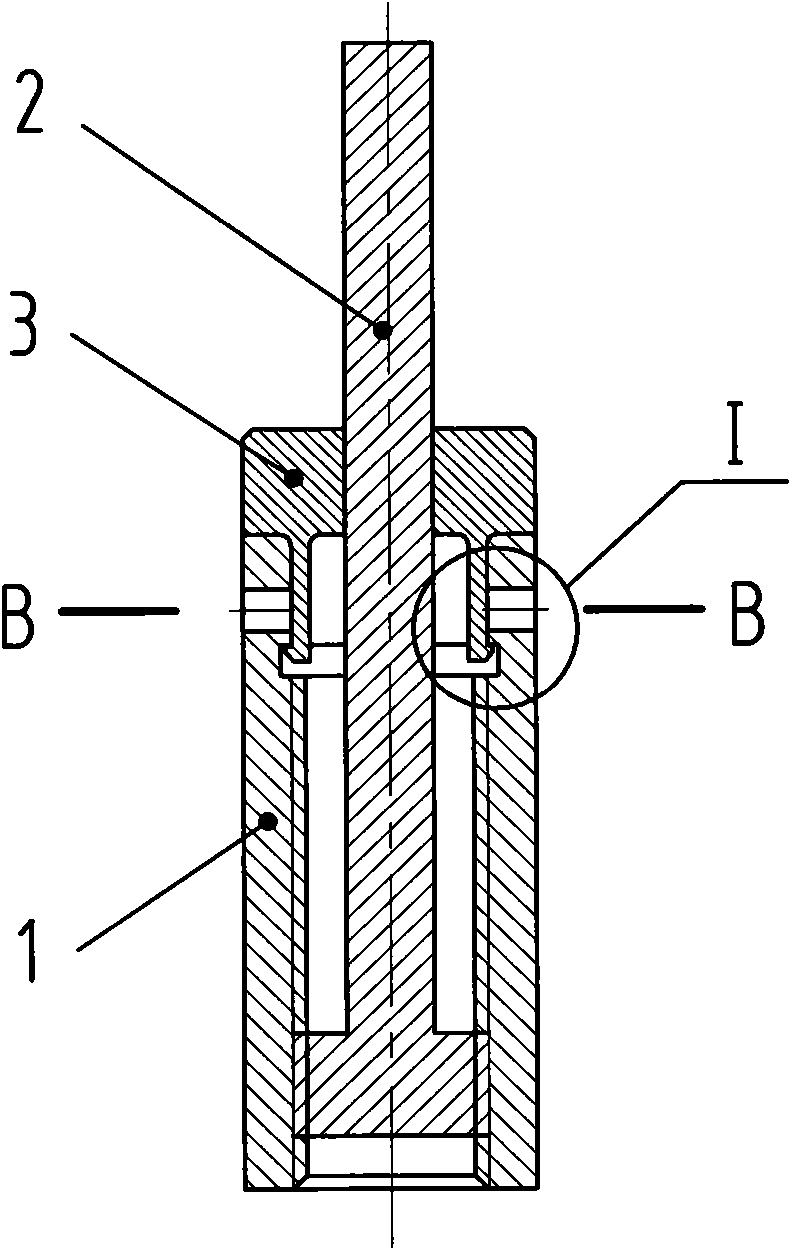

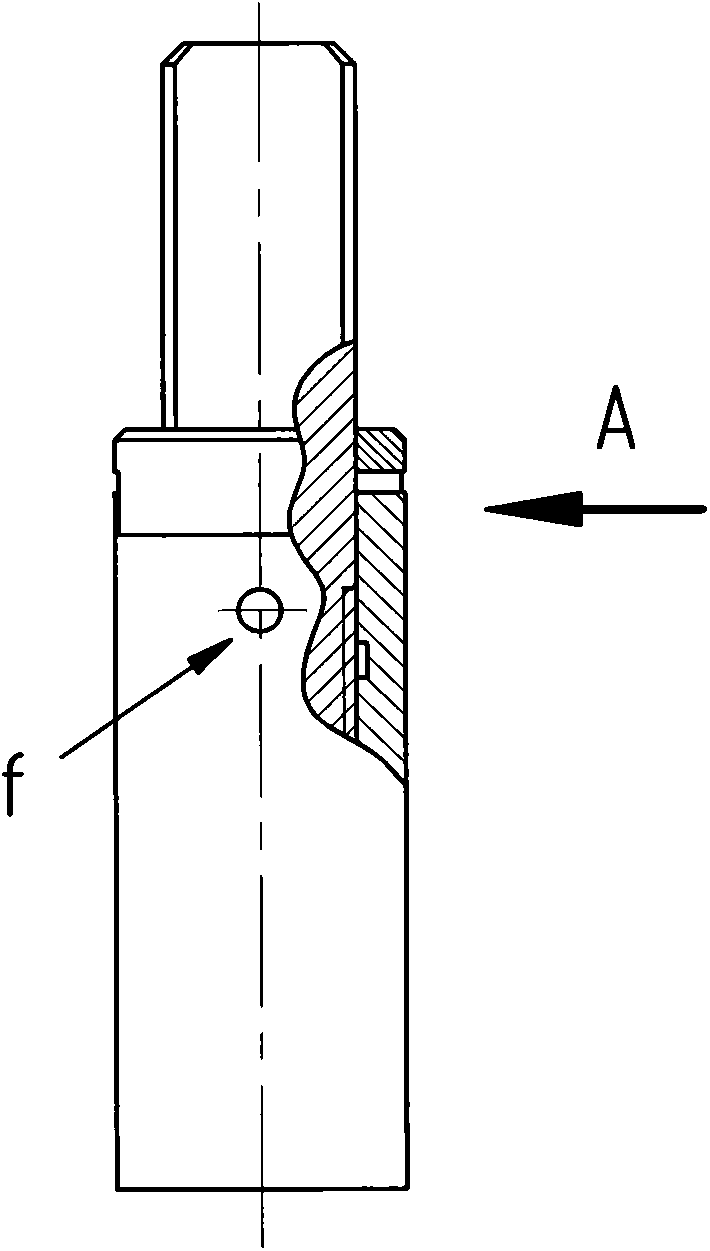

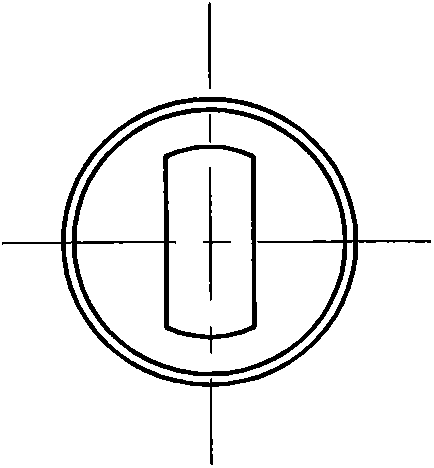

[0014] The adjustable plate stirring tooth assembly of the granulator is composed of the stirring tooth seat tube (1), the plate stirring tooth (2) and the fixed cover (3); the installation method is to move the lower end of the plate stirring tooth from the upper part of the stirring tooth seat tube to Screw down, insert the guide flat hole of the fixed cover into the flat stirring tooth, align the two grooves on the fixed cover with the two bosses (c) on the stirring tooth seat tube and push down to the end to complete the installation; The method of maintenance and disassembly is to push inward with a tool from the two holes (f) on the stirrer seat tube, and at the same time press the fixed cover with a tool from the gap above the boss (c), so that the fixed cover can be moved upwards and removed. Down.

[0015] The orientations of the two bosses (c) and the two holes (f) on the upper part of the stirrer seat tube are 90° different.

[0016] The adjustable flat-plate stirr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap