Automatic plastic coating machine for protective tube of flexible shaft

A kind of plastic wrapping machine, automatic technology, applied in the direction of application, household utensils, tubular objects, etc., can solve the problems of increasing resistance, easy to wear the surface of the protective tube, deformation of the protective tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

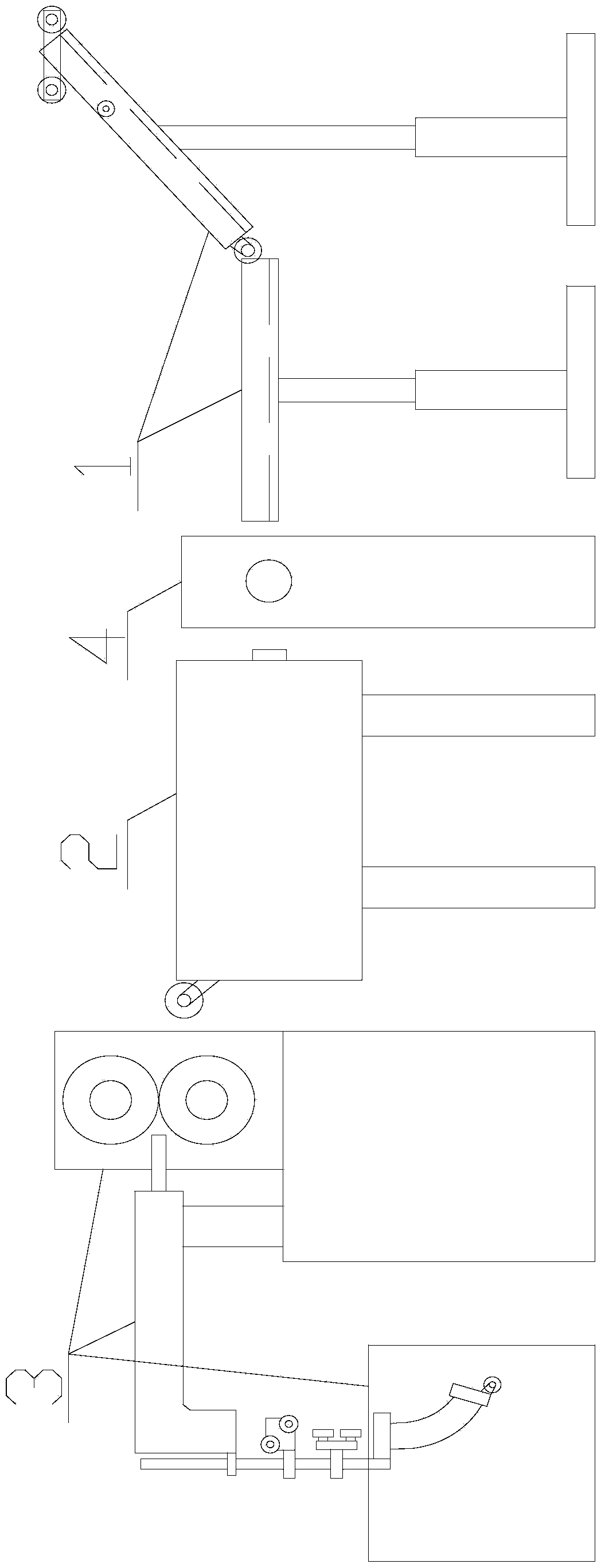

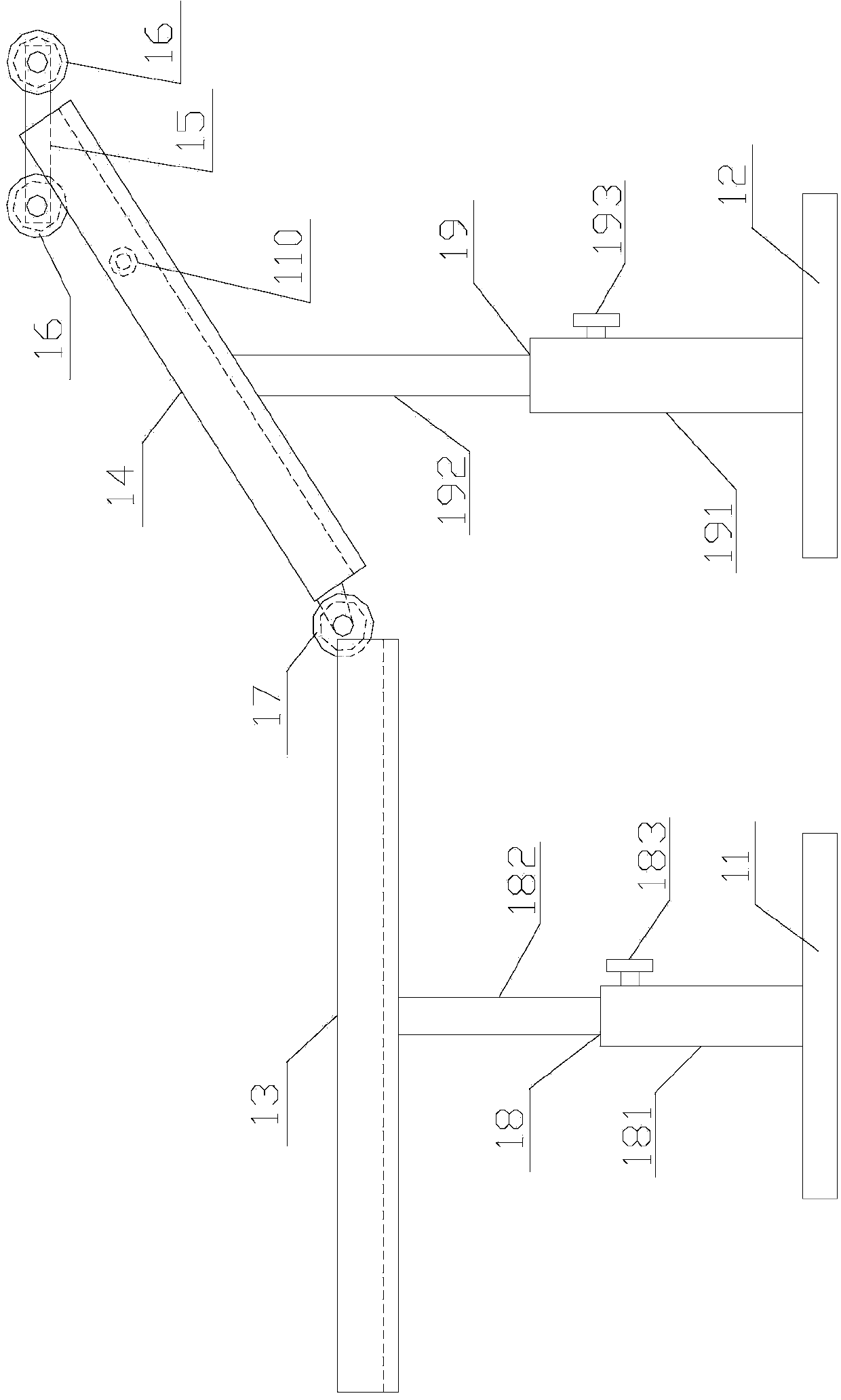

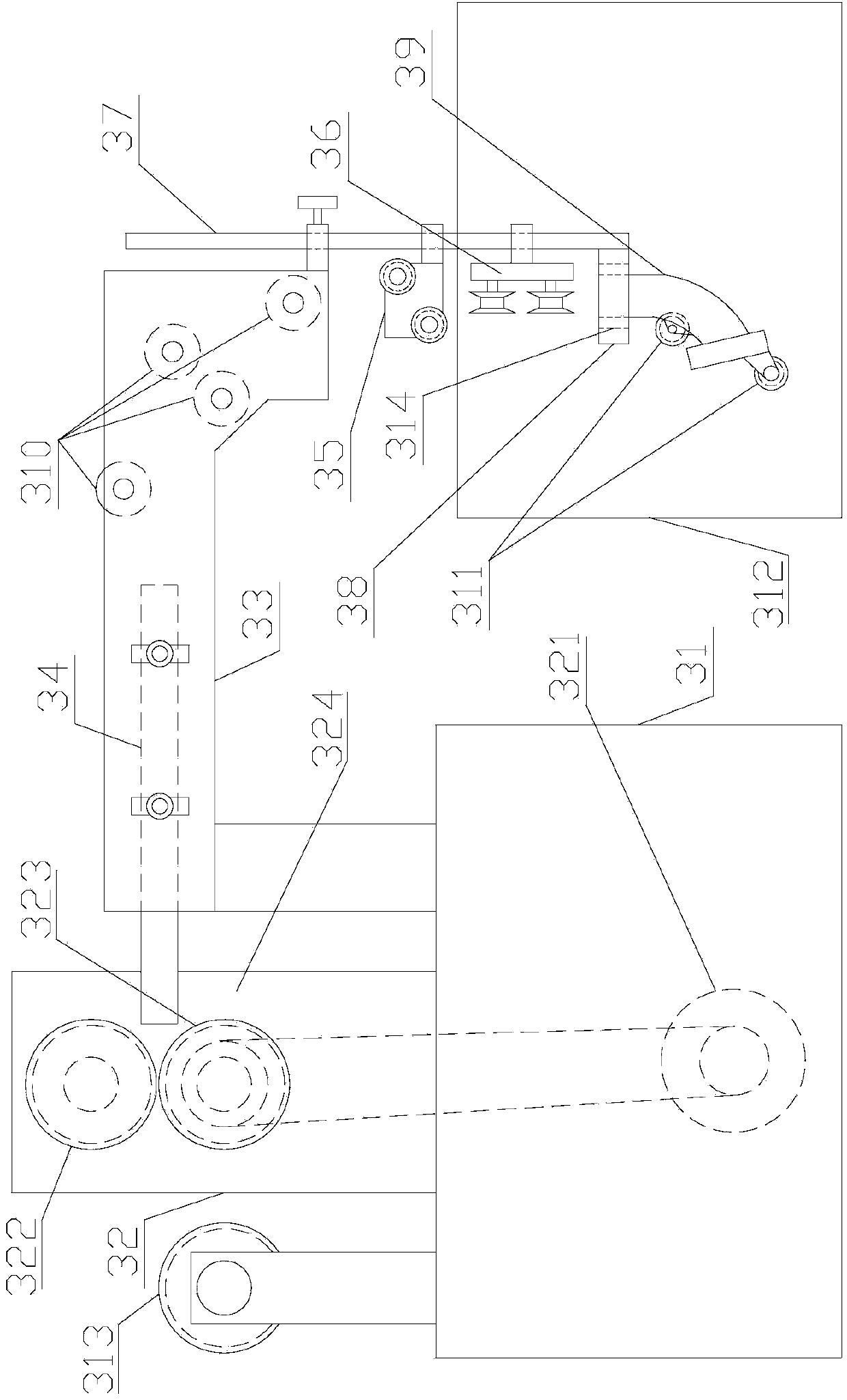

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , the present invention is an automatic overmolding machine for protective tubes for flexible shafts, comprising a tube inlet guide device 1, a water cooling device 2, a coiling device 3 and a plastic extruder 4, and the tube inlet guide device 1, plastic extruder 4 , the water cooling device 2 and the coiling device 3 are arranged in sequence from front to back, and the pipe inlet guide device 11 includes a first base 11, a second base 12, a first material guide trough 13, a second material guide trough 14, a third Mounting plate 15, first guide wheel 16, second guide wheel 17, first support bar 18 second support bar 19 and first positioning wheel 110, described first base 11 is provided with first support bar 18, described The first support rod 18 is provided with a first material guide groove 13, the second base 12 is provided with a second support rod 19, and the second support rod 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap