A waste copper pipe collection device

A collection device, copper tube technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of small carrying capacity, puncture, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

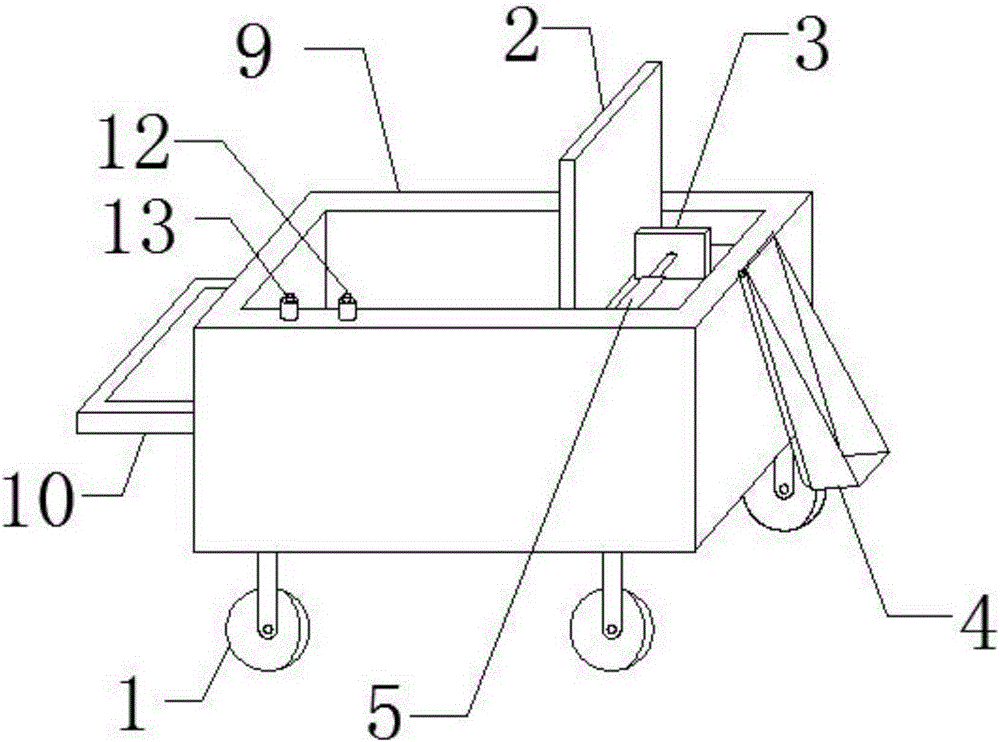

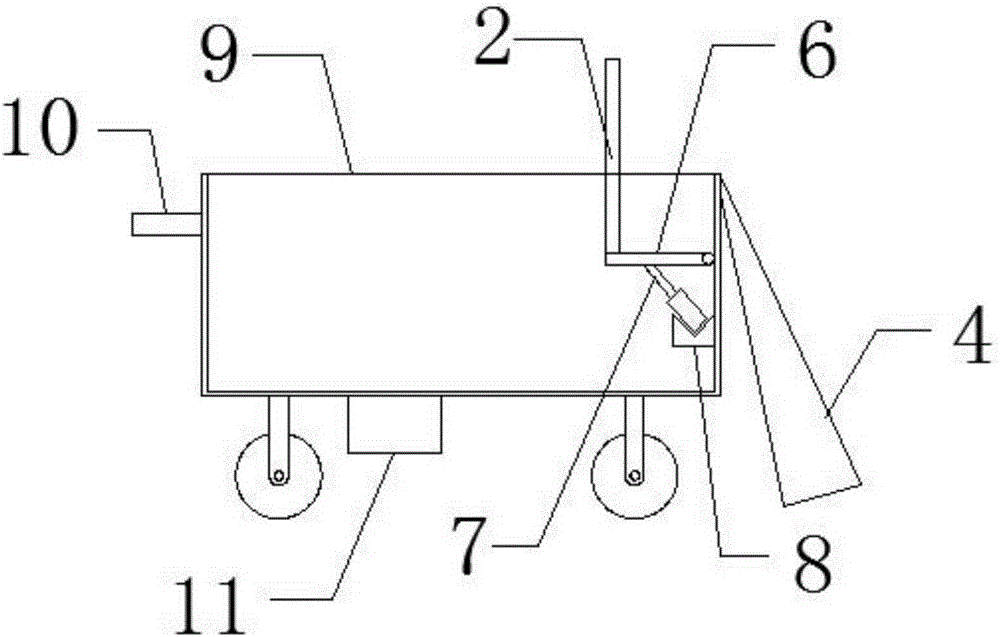

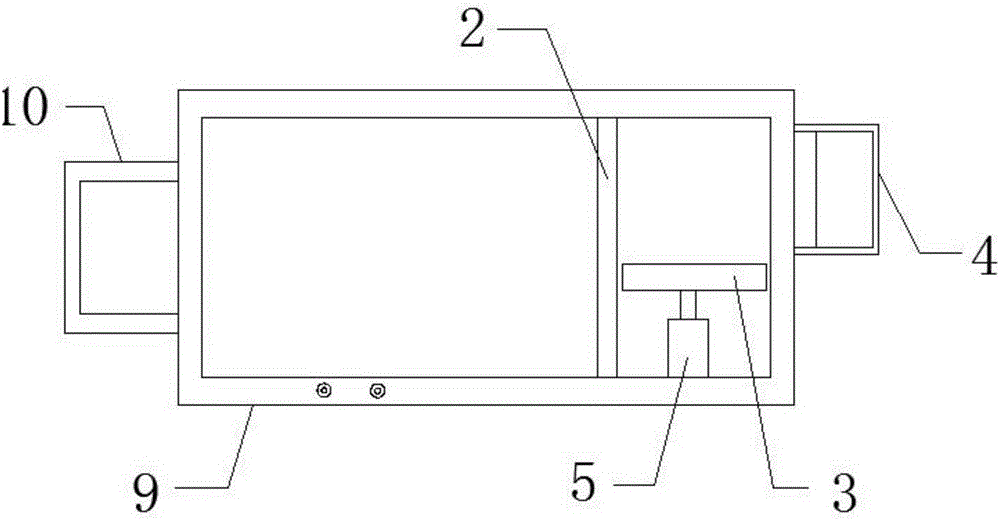

[0019] Embodiment 1: a kind of scrap copper pipe collecting device, its structure is as Figure 1-3 Shown: includes trolley 1, and this trolley has compartment 9, and a baffle plate 2 is vertically arranged in described compartment 9, and the top end of this baffle plate 2 protrudes from compartment, and compartment 9 is also provided with bracket 8 inside, on which bracket 8 is installed There is a first cylinder 7, the piston rod of the first cylinder 7 is hinged with the base plate 6, and one side of the base plate 6 is hinged with the inner wall of the compartment 9; Squeeze the bin, the squeeze bin is provided with an extruding mechanism, and the outer wall of the compartment 9 is also provided with a waste copper pipe collecting mechanism.

[0020] Described extruding mechanism comprises the second air cylinder 5 that is positioned at extruding bin, and second air cylinder 5 is fixedly connected with compartment 9 inner wall by bolt, and the piston rod of second air cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com