Pulley device and construction method for optical cable distribution thereby

A construction method and pulley technology, applied in the direction of components with teeth, optical fiber/cable installation, belts/chains/gears, etc., can solve the problems of extreme lateral pressure and friction of optical cables, and achieve the effect of saving resources and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

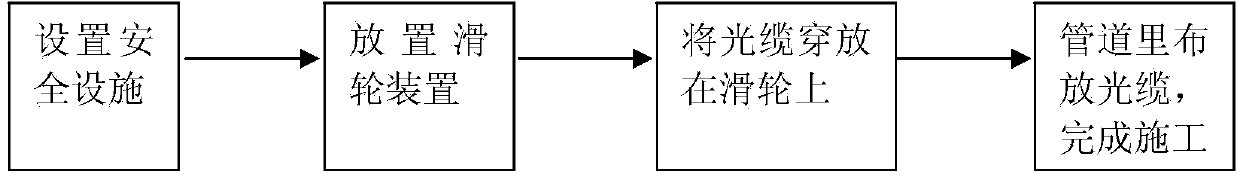

[0027] like figure 1 and figure 2 As shown, the invention provides a construction method for laying an optical cable with a pulley device, the method comprising the steps of:

[0028] Step 1: Set up safety facilities around the construction manhole;

[0029] Place safety cones, safety warning signs, etc.;

[0030] Step 2: Place a pulley device around the well, place the pulley device on the well in the direction of laying the optical cable, and buckle the base on the well ring;

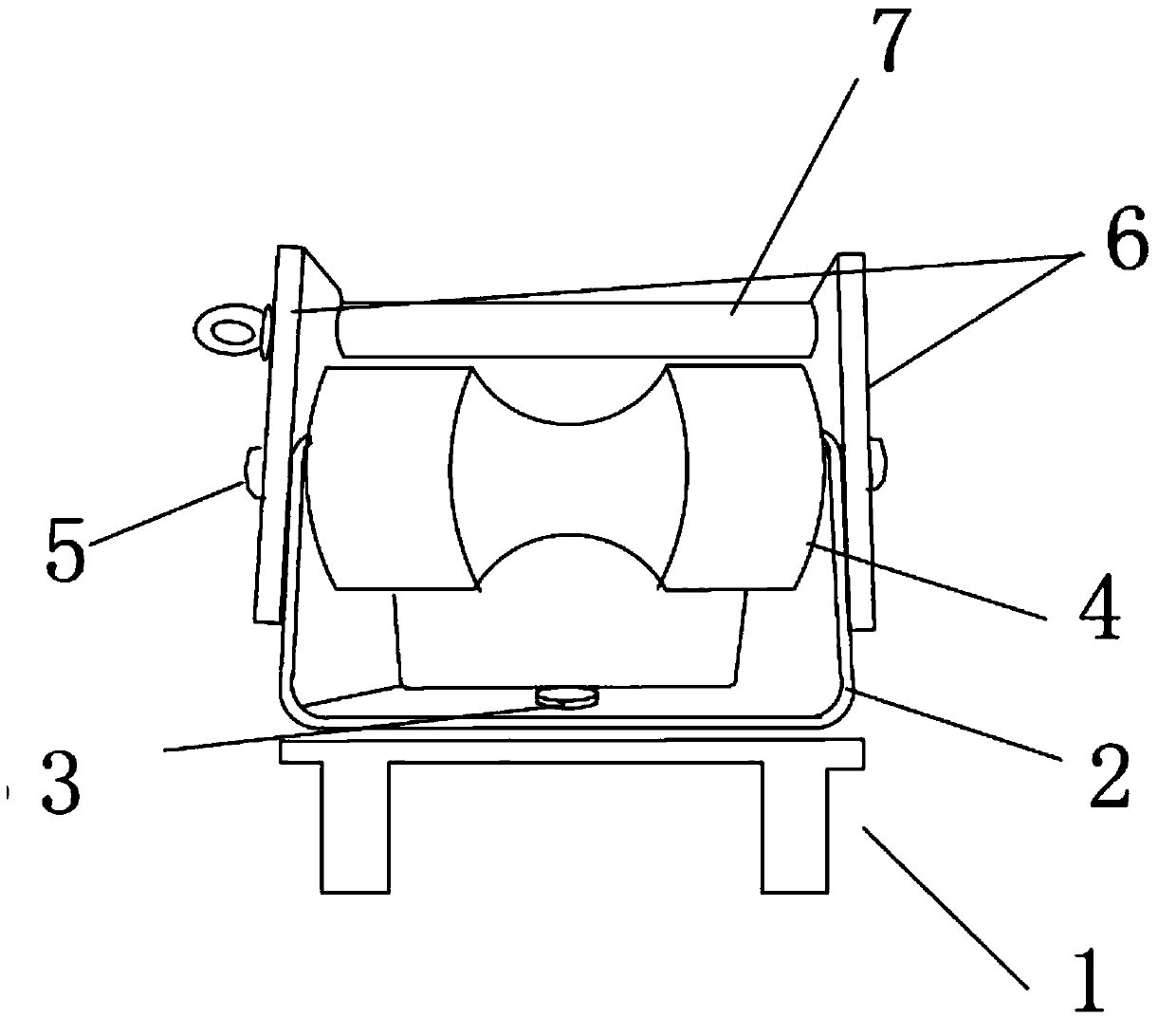

[0031] Step 3: Adjust the angle of the pulley device, and put the optical cable on the pulley 4;

[0032] According to the force direction of the optical cable construction, adjust the angle of the U-shaped block 2 of the pulley device, put the optical cable on the pulley 4, and the pulley 4 rotates through the bearing of the bearing screw 5 in the middle of the U-shaped block 2;

[0033] Step 4: Lay optical cables in the construction pipeline to complete the construction.

[0034] Among them, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com