Sea water desalting device based on supercavitation technology

A supercavitation technology, which is applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc., can solve the problem of low energy density and achieve the effect of solving the residual non-degradable pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

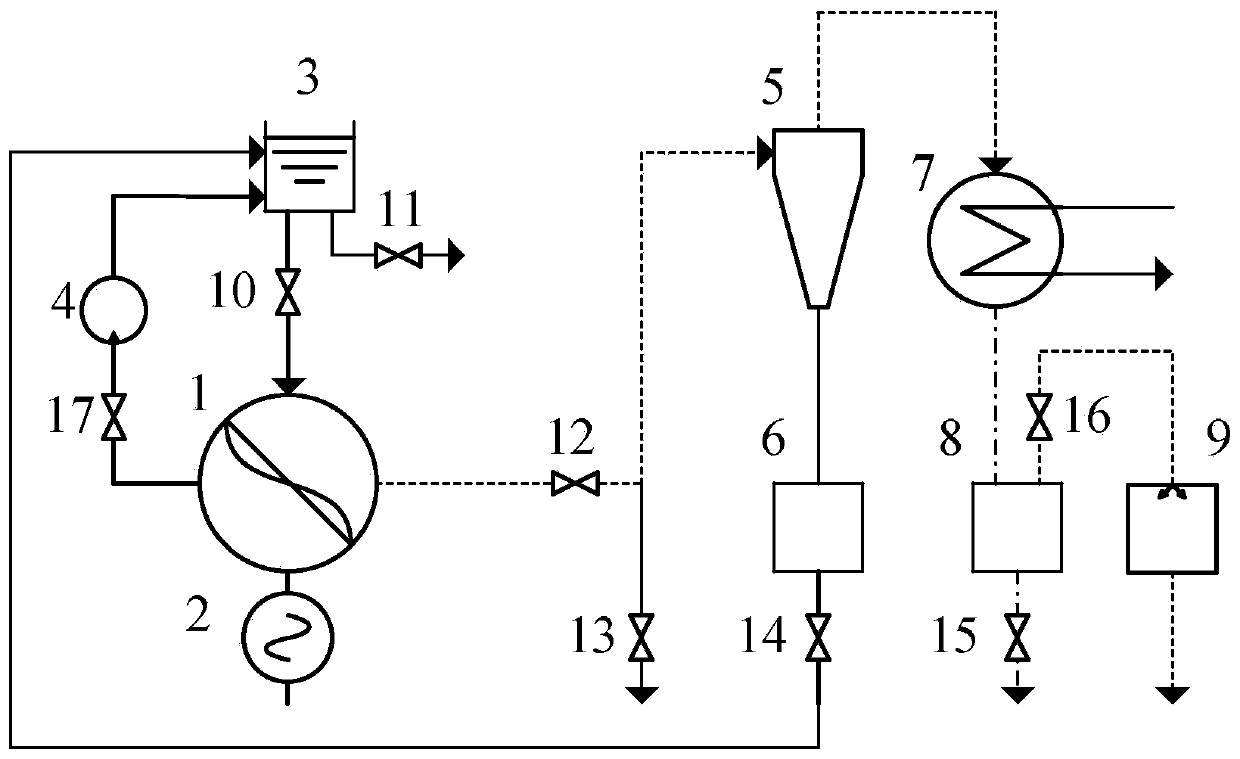

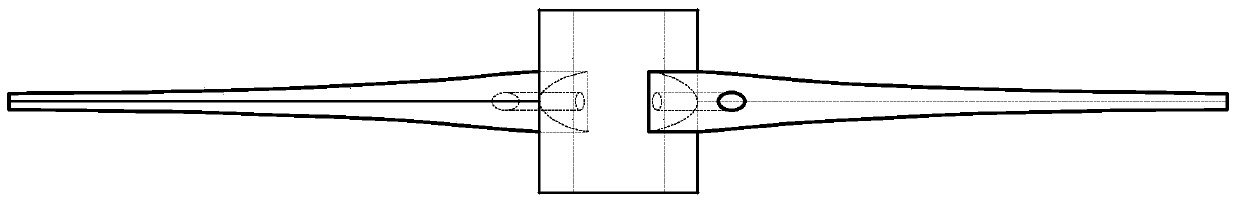

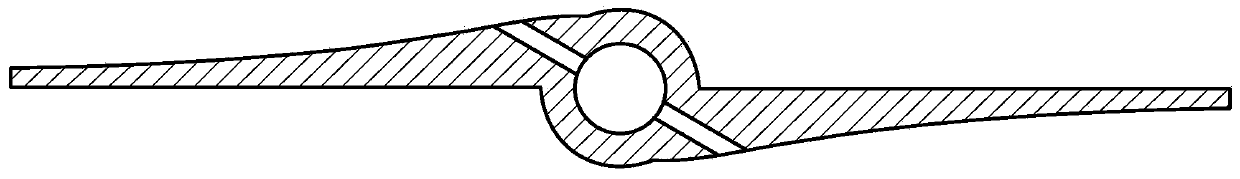

[0012] Specific implementation mode two: as figure 2 and image 3 As shown, the number of blades of the rotary supercavitation evaporator 1 in this embodiment is two. Such a design can ensure the dynamic and static balance of the rotating blades, and at the same time, there is a large space between the blades to form a large-sized supercavitation. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: as figure 2 and image 3 As shown, the blade in this embodiment is a wedge-shaped blade, and the cross-section of the blade from the center to the edge is tapered from large to small. With such a design, the length of the cavitation can reach the maximum at different radii, so that the supercavitation with the largest size can be obtained to increase the water vapor production. Other compositions and connections are the same as those in Embodiment 1 or 2.

specific Embodiment approach 4

[0014] Embodiment 4: The cyclone separator described in this embodiment is a gas-liquid separator. In such a design, the water droplets entrained in the steam extraction process are separated and converged to the source water droplet collection tank 6, and the steam and non-condensable gas flow to the condenser 7 through the upper outlet of the cyclone separator 5. Other components and connections are the same as those in the third embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com