Vibration alarming system for full-automatic washing machine

A fully automatic washing machine and alarm system technology, applied in the field of washing machines, can solve problems such as danger, large vibration and noise of the washing machine box, and movement of damaged washing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

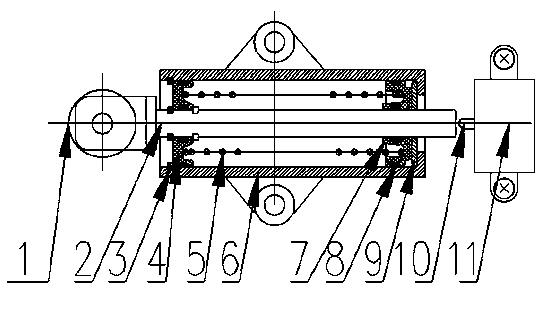

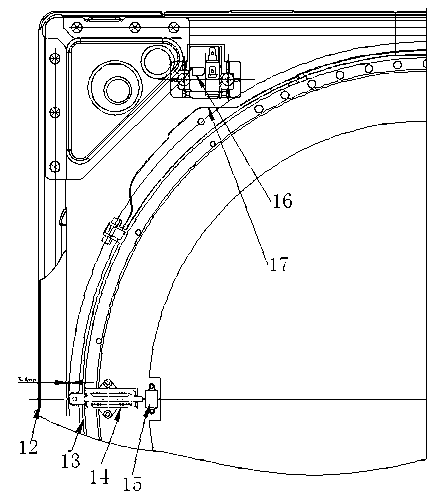

[0022] The invention is applicable to wave wheel washing machines, drum washing machines and stirring washing machines. The present invention will be further described below in conjunction with accompanying drawing:

[0023] Such as Figure 1-Figure 2 As shown, several vibration alarm systems are respectively installed at the place where the gap between the outer tub of the washing machine and the cabinet is the smallest, or where the vibration amplitude of the outer tub of the washing machine is the largest. A vibration alarm system for a fully automatic washing machine includes a safety bar assembly 14 and a micro switch assembly 15 located on one side of the safety bar assembly 14 .

[0024] Specifically, the safety rod assembly 14 includes a safety rod 2 , a safety rod seat 6 , a first sealing ring 4 and a second sealing ring 7 . The first sealing ring 4 and the second sealing ring 7 are located in the middle of the safety bar seat 6 , and a return spring 5 is fixedly ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com