3d printer working status online monitoring device

A 3D printer, working state technology, applied in measurement devices, computer control, instruments, etc., can solve the problems of inconvenient operation, inability to provide intuitive and accurate feedback information for operators, and failure to provide operators with the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

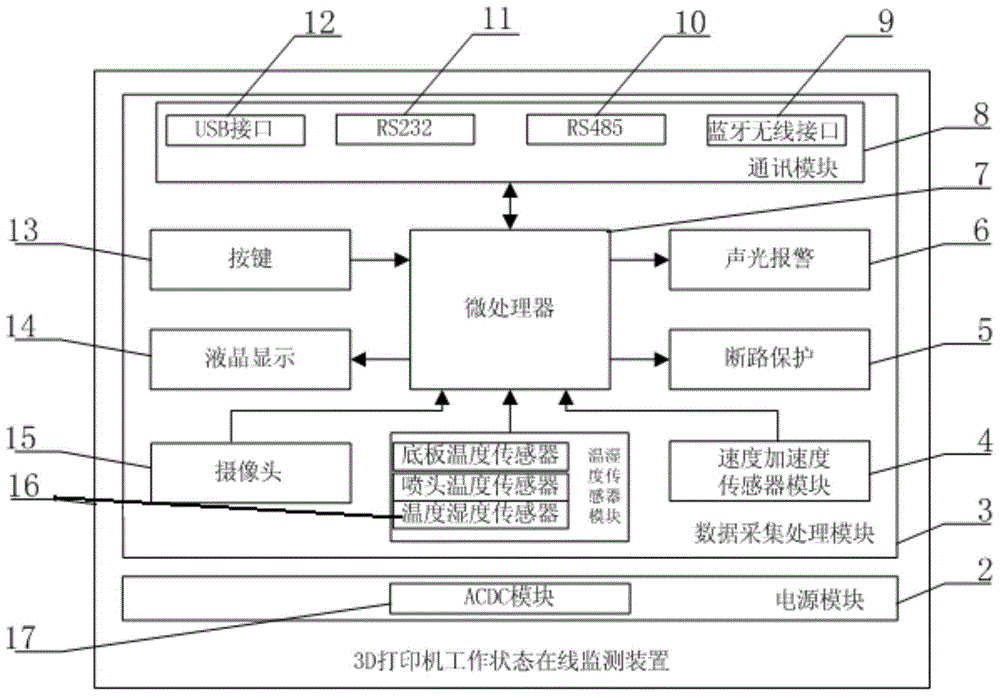

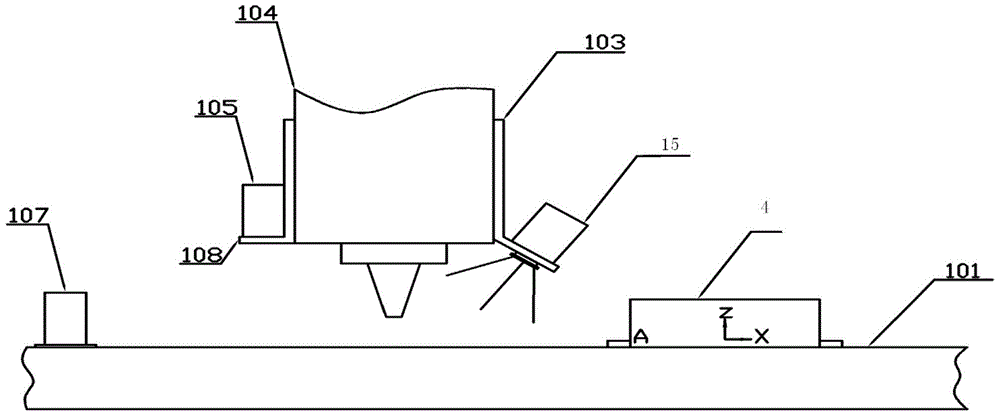

[0030] Such as figure 1 As shown, the online monitoring device for the working state of the 3D printer of the present invention includes a power supply module 2 and a data collection and processing module 3 .

[0031] The power supply module includes an ACDC module 17, which supplies power to the device and is independent of the 3D printer power supply.

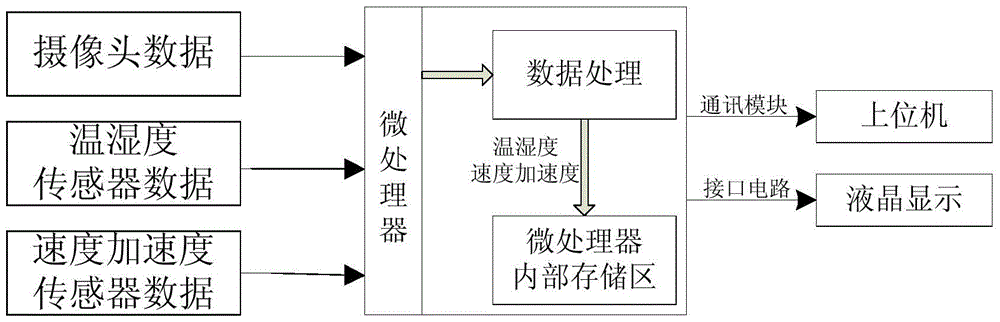

[0032] The data acquisition and processing module includes a microprocessor 7, a communication module 8, a camera 15, a temperature and humidity sensor module 16, a speed acceleration sensor module 4, an audible and visual alarm module 6, an open circuit protection module 5, a liquid crystal display 14, and a key input module 13.

[0033] The communication module provides USB interface 12, RS232 interface 11, RS485 interface 10 and Bluetooth wireless interface 9 respectively. The microprocessor transmits data to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com