Loading system for applying vertical loads based on geotechnical centrifuge

A geotechnical centrifuge and vertical load technology, applied in soil material testing, material inspection products, etc., can solve the problems of difficult to guarantee system operation reliability, wear of worm gear, poor anti-interference ability, etc. Take convenient, effective and high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

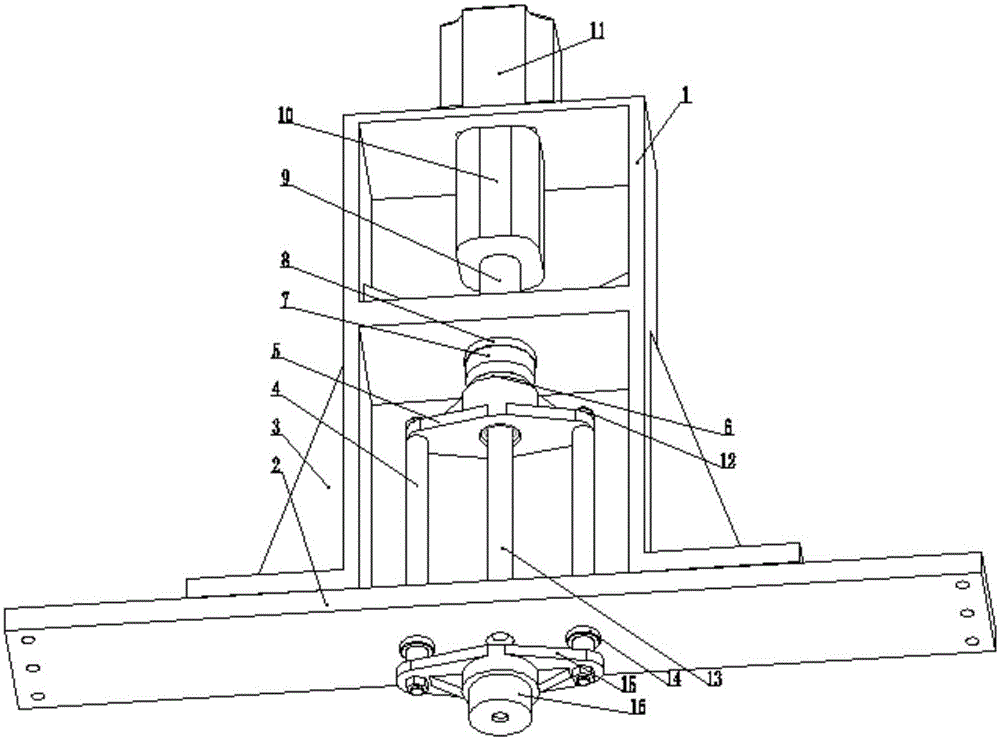

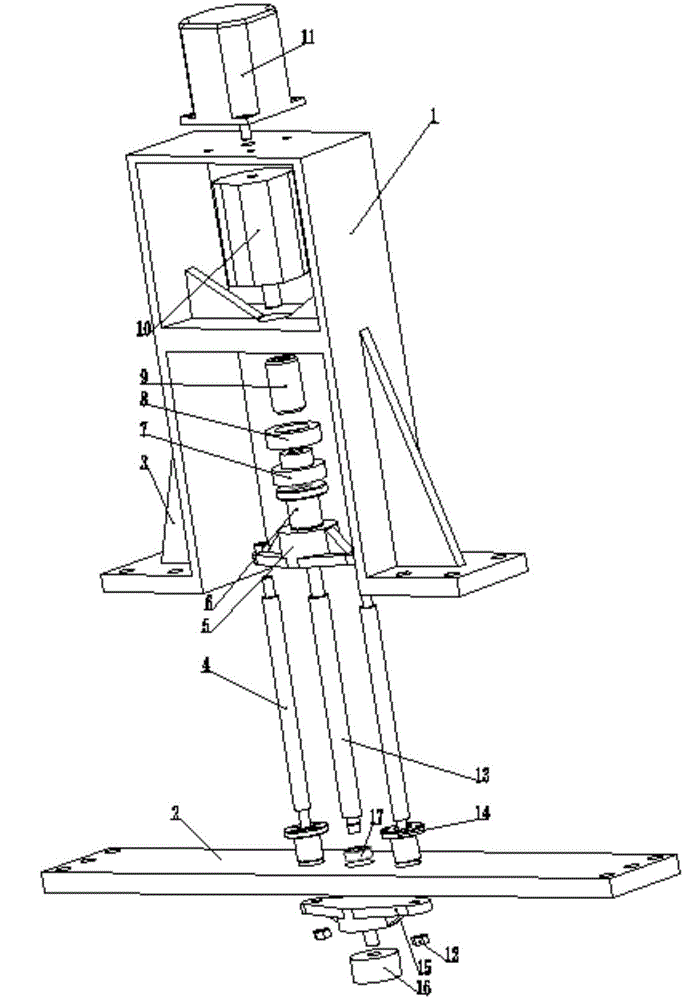

[0025] Further description will be made below in conjunction with the embodiments and accompanying drawings.

[0026] The present invention is based on the loading system of geotechnical centrifuge, and its work process is as follows: stepper motor 11 obtains the control signal command that is sent by controller, just rotates into speed reducer 10 and shaft coupling 9 and transmits rotation to screw mandrel 13, rotates After the screw nut 6 becomes a linear motion, the screw nut 6 passes the linear motion through the screw nut base 5 and the thrust rod 4 to push the sensor thrust seat 15 and the pressure sensor 16 to move downward (load). The pressure sensor 16 acts directly on the model, so as to achieve the purpose of loading. The controller monitors the magnitude of the applied load in real time. When the load requirement is met, the controller sends an instruction to the motor 11 to stop loading; Initial position to prepare for the next loading job.

[0027] In the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com