A method for measuring winding temperature of transformer

A technology of winding temperature and measurement method, which is applied in the directions of thermometers, thermometers, and heat measurement using electrical/magnetic components directly sensitive to heat, which can solve the problems that affect the indication temperature display of the meter, few practical applications, and difficult maintenance. , to achieve the effect of reducing maintenance workload, accurate and reliable calculation, and reducing maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

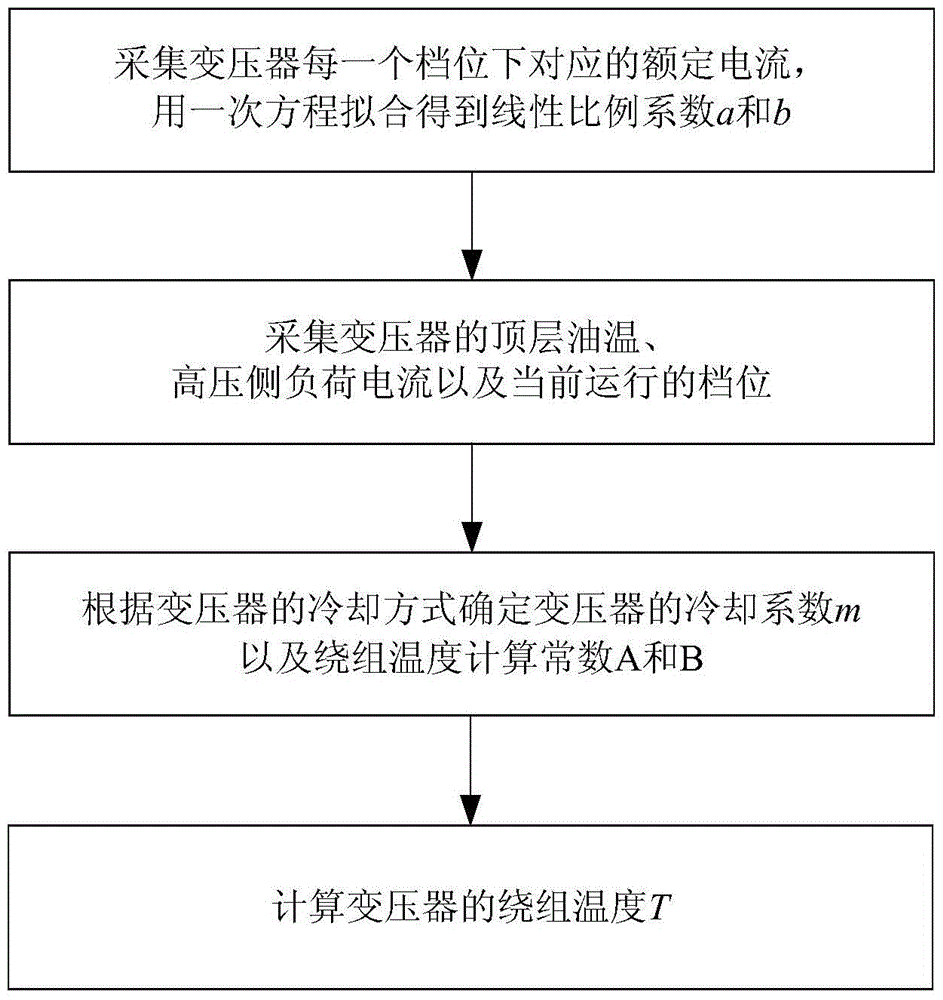

[0023] Such as figure 1 As shown, the implementation steps of the method for measuring the winding temperature of a transformer in this embodiment are as follows:

[0024] 1) Collect the rated current corresponding to each gear of the transformer, and obtain the linear proportional coefficients a and b according to the corresponding rated current under each gear with the linear equation shown in formula (1);

[0025] Ie=aD+b (1)

[0026] In the formula (1), Ie represents the rated current, D represents the gear position, and a and b represent the linear proportional coefficients respectively.

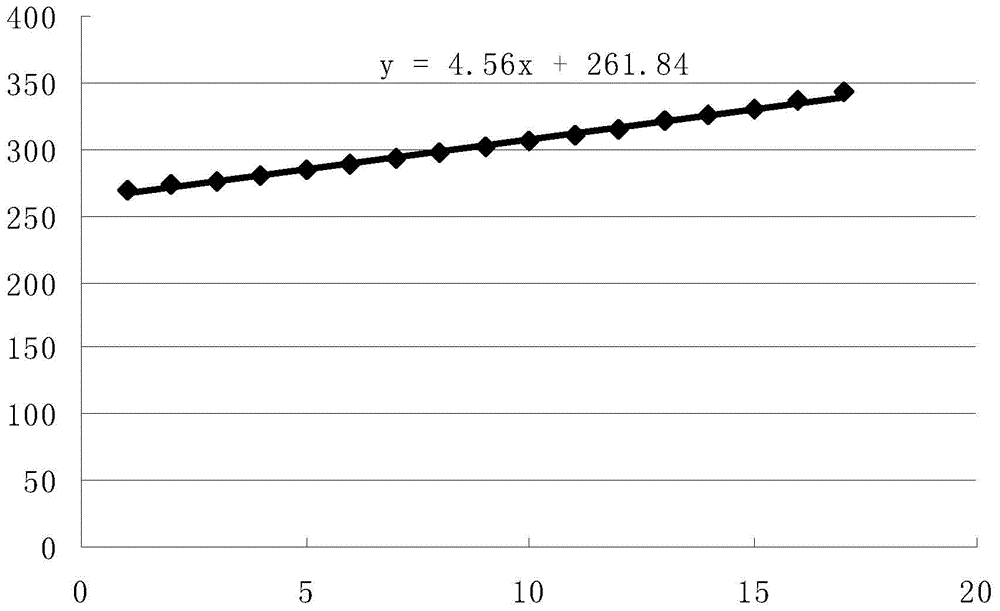

[0027] Taking the 2# main transformer of the Mocheng Transformer of Yueyang Power Supply Company as an example, the relationship of the rated current corresponding to each gear of the 2# main transformer of the Mocheng Transformer is shown in Table 1. Table 1: The relationship table of rated current corresponding to each gear of Hucheng Transformer 2# main transformer.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com