Metal mask plate for solid-state dye sensitized solar cell electrode evaporation

A solar cell and metal mask technology, which is applied in the field of metal masks, can solve problems such as uneven electrode thickness and mask deformation, and achieve the effects of reducing manufacturing difficulty, shortening distance, and reducing the risk of edge color mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

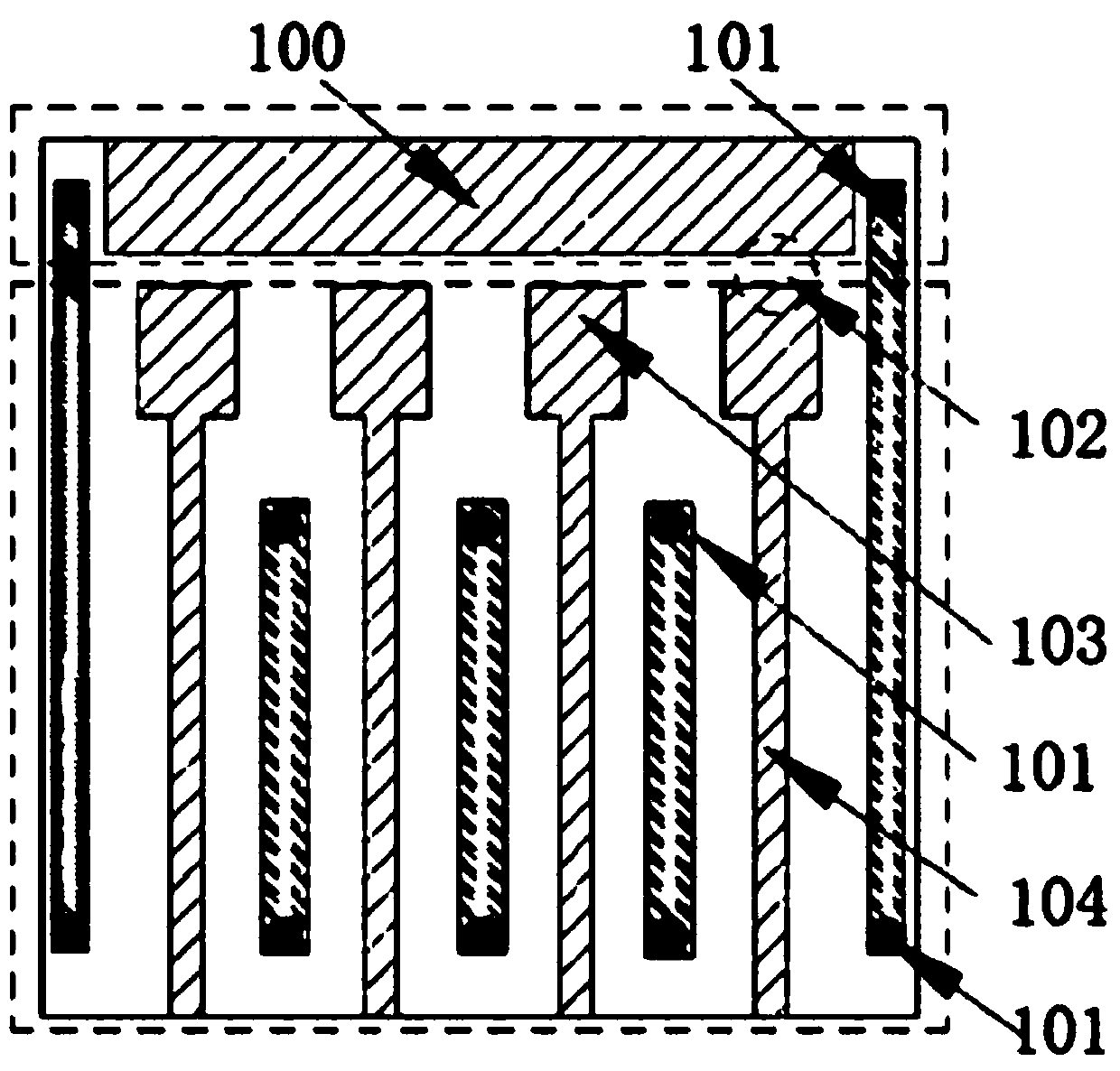

[0019] Such as figure 1 As shown, a mask plate used for electrode evaporation of solid-state dye-sensitized solar cells includes a first area and a second area, and the first area and the second area include an evaporation area and a non-evaporation area. area, 100 is the first vapor deposition rectangular area, 101 is a fixed small hole, and there are rib support members between the small holes, which shortens the distance between the cathode and the transition area, 102 is the gap between the first area and the second area, and 103 is The evaporation rectangular area in the second area, 104 is a transition area.

[0020] There are 2-3 fixed holes between the slits, 1-4 fixed holes on the edge of the first zone and the second zone, and the distance between the fixed holes and the rectangular area of the second zone is 2mm-3mm. The thickness of the plate body is about 300-500μm, the distance between each column of small holes in the slit is 3mm-8mm, the length of the ribbed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Edge width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com