AMOLED (Active Matrix Organic Light Emitting Display) metal mask plate

A mask and slit technology, applied in the field of organic light-emitting display, can solve problems such as narrow edge width, shorten the distance, reduce the risk of edge color mixing, and achieve the effect of narrowing the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

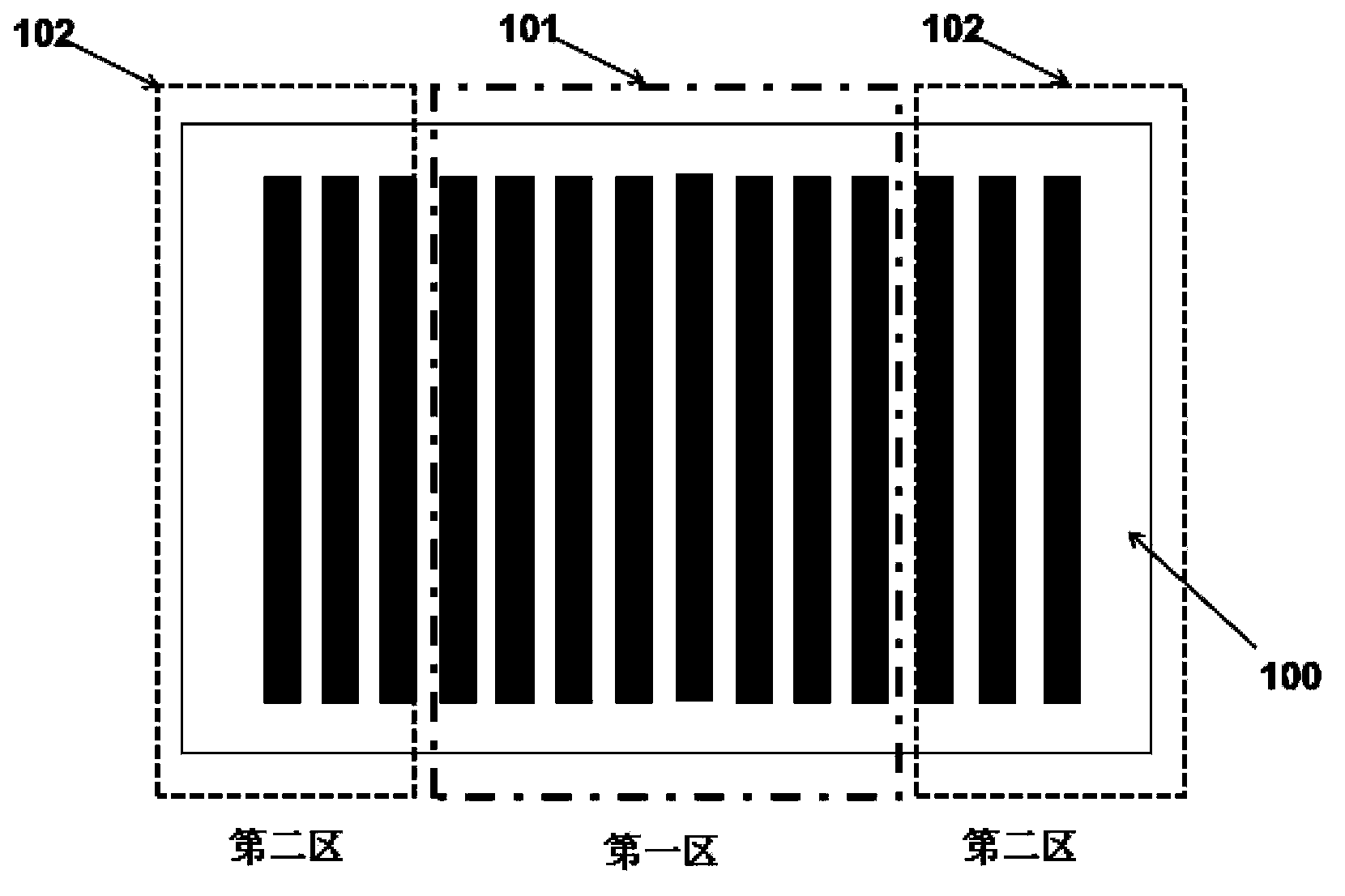

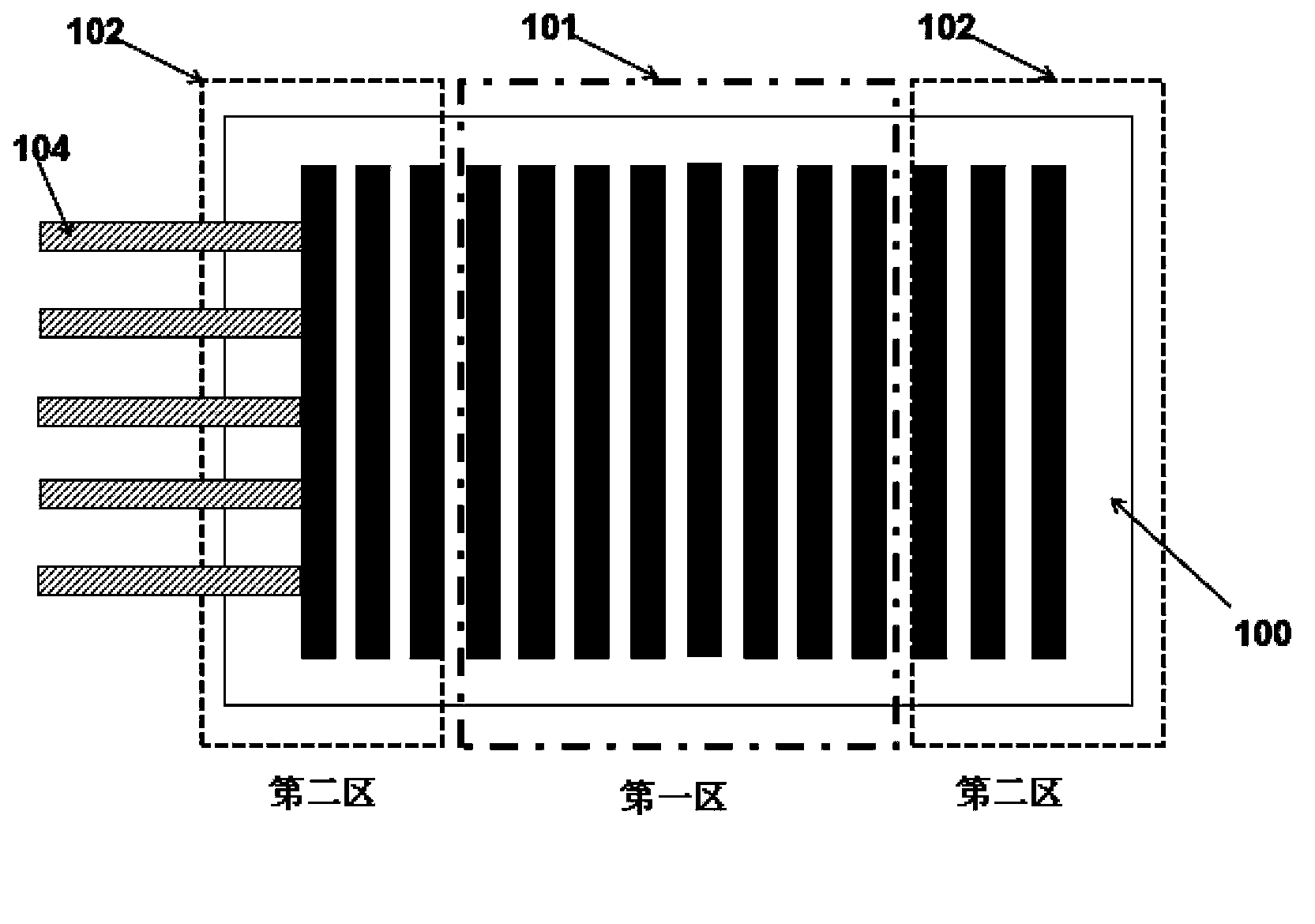

[0039] This embodiment provides a mask plate for AMOLED evaporation, please refer to image 3 , image 3 It is a schematic diagram of the mask plate according to the first embodiment of the present invention, and the mask plate includes:

[0040] Bottom member 200, and a first area and a second area located on the bottom member 200, the first area corresponds to the display area of AMOLED, the second area corresponds to the transition area of AMOLED, and the second area is set at the second The left and right sides of a zone;

[0041] A plurality of left and right parallel slits 201 provided on the bottom member 200 and penetrating the bottom member 200 are provided in the first region, wherein the plurality of slits 201 have a predetermined length and extend in a vertical direction, the The slit 201 is used for vapor deposition of color pixels in the AMOLED display area;

[0042] Four rows of rectangular small holes 202 are arranged in the second area, and rib suppo...

no. 2 example

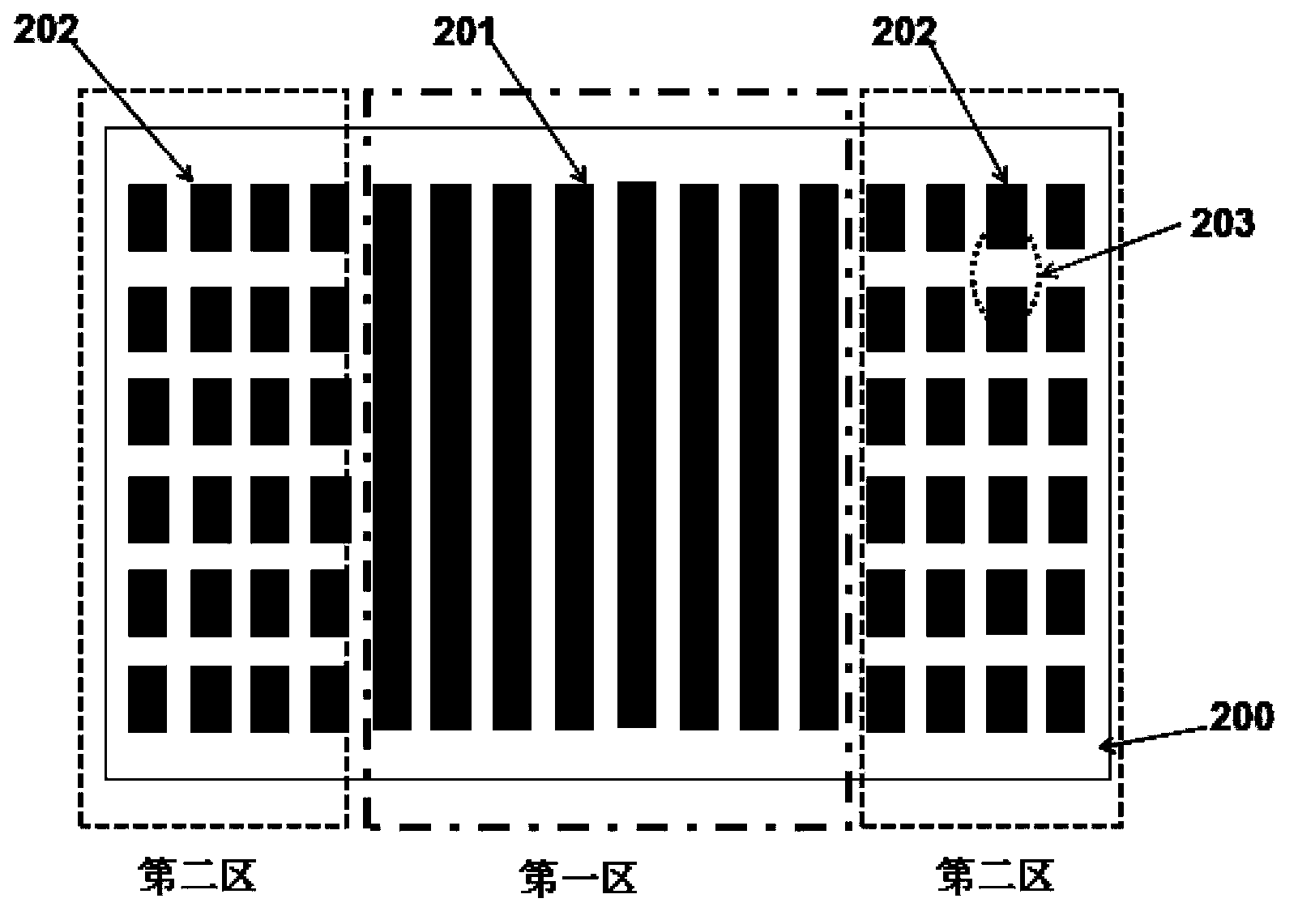

[0054] The second embodiment of the present invention has been optimized on the basis of the first embodiment. For details, please refer to Figure 4 , Figure 4 It is a schematic diagram of the mask plate of the second embodiment of the present invention. Compared with the first embodiment, the second embodiment is better than the first embodiment in that: a region 304 of a cathode via hole is provided in the second region 302 .

[0055] The area 304 where the cathode via hole is provided at least partly coincides with the area corresponding to the second area 302 , specifically, coincides with the area of the rib support part 303 , and is between the upper and lower small holes 302 of the corresponding rib support part 303 .

[0056] Compared with the scheme in the prior art, where the area of the cathode via hole must be set in the area other than the slit in the second area, in this embodiment, the area for setting the cathode via hole is set between two adjacent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com