Apparatus for forming complex nanoparticle film and method for forming nanoparticle film using same

A nano-particle and multi-component technology, which is applied in the field of nano-particle film forming devices of multi-component system, can solve the problems such as the limitation of the installation position of metal materials, the difficulty of adjusting the particle diameter and particle amount, and the configuration of metal materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

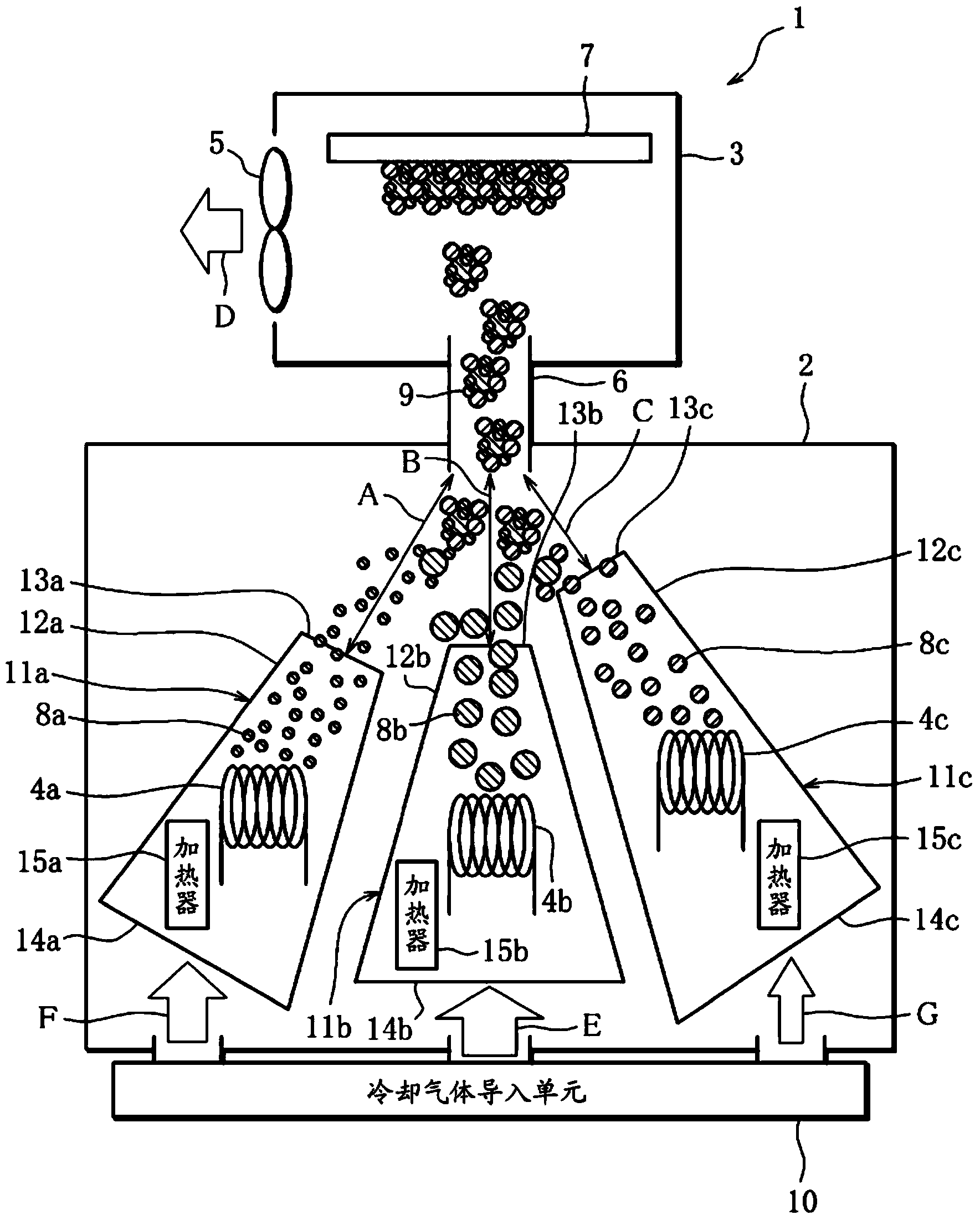

[0031] Such as figure 1 As shown, the nanoparticle film forming apparatus 1 of the present invention has a production chamber 2 and a film formation chamber 3 . A plurality of metal materials (three metal materials 4 a to 4 c in the drawing) are arranged in the production chamber 2 . The generation chamber 2 is used to generate multi-component nanoparticles (alloy nanoparticles) 9 in which the nanoparticles 8a to 8c of the metal materials 4a to 4c are bonded. For the metal materials 4a to 4c, for example, metal wires made of magnesium, nickel, or alloys thereof can be used. A cooling gas introduction unit 10 is installed in the generation chamber 2 , and a cooling gas is introduced from the cooling gas introduction unit 10 .

[0032] An exhaust unit (vacuum fan in the drawing) 5 is installed in the film forming chamber 3, and the film forming chamber 3 is evacuated by the exhaust unit 5 (arrow D direction). The production chamber 2 is connected to the film formation chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com