Single-sided corrugated plate type pulsating heat pipe

A technology of pulsating heat pipes and corrugated plates, applied in indirect heat exchangers, lighting and heating equipment, electrical components, etc., can solve problems such as complex processes, weak capillary action, and unsatisfactory heat transfer performance, and achieve wide source of materials , low price, excellent heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

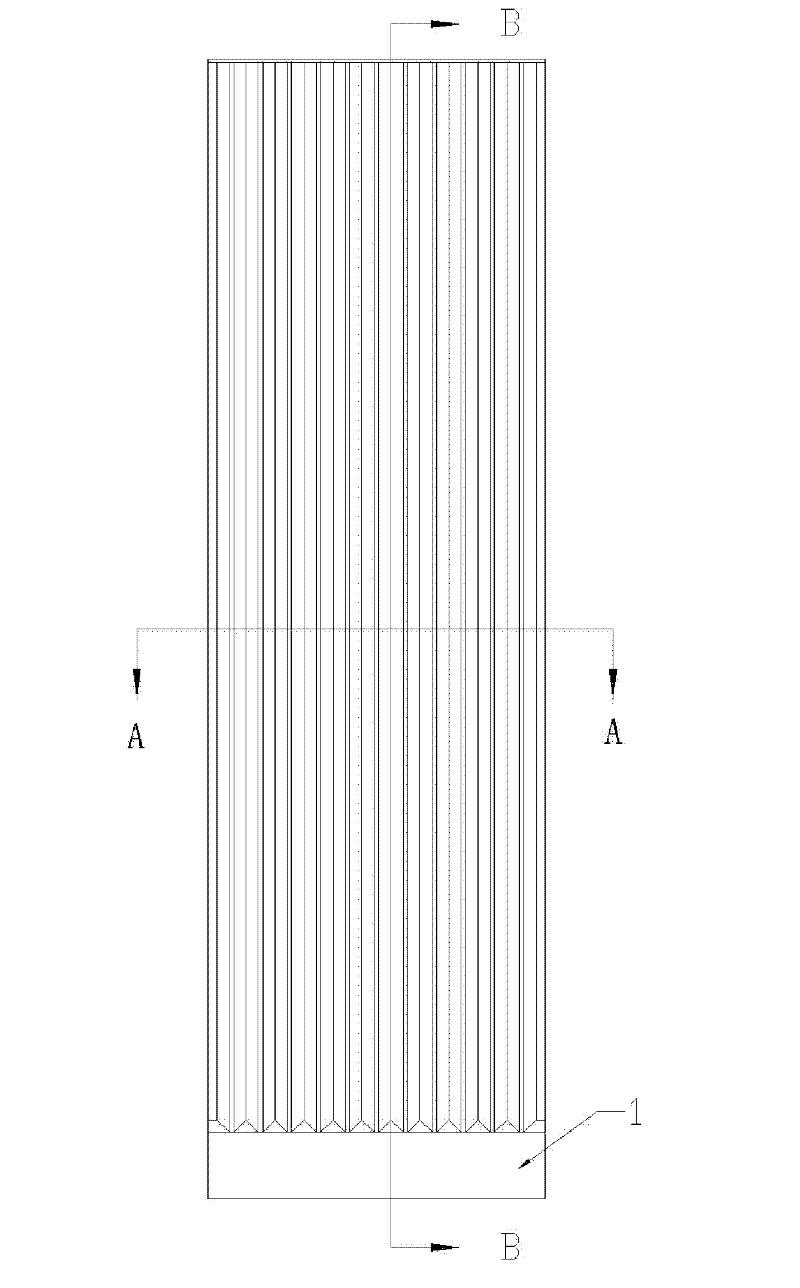

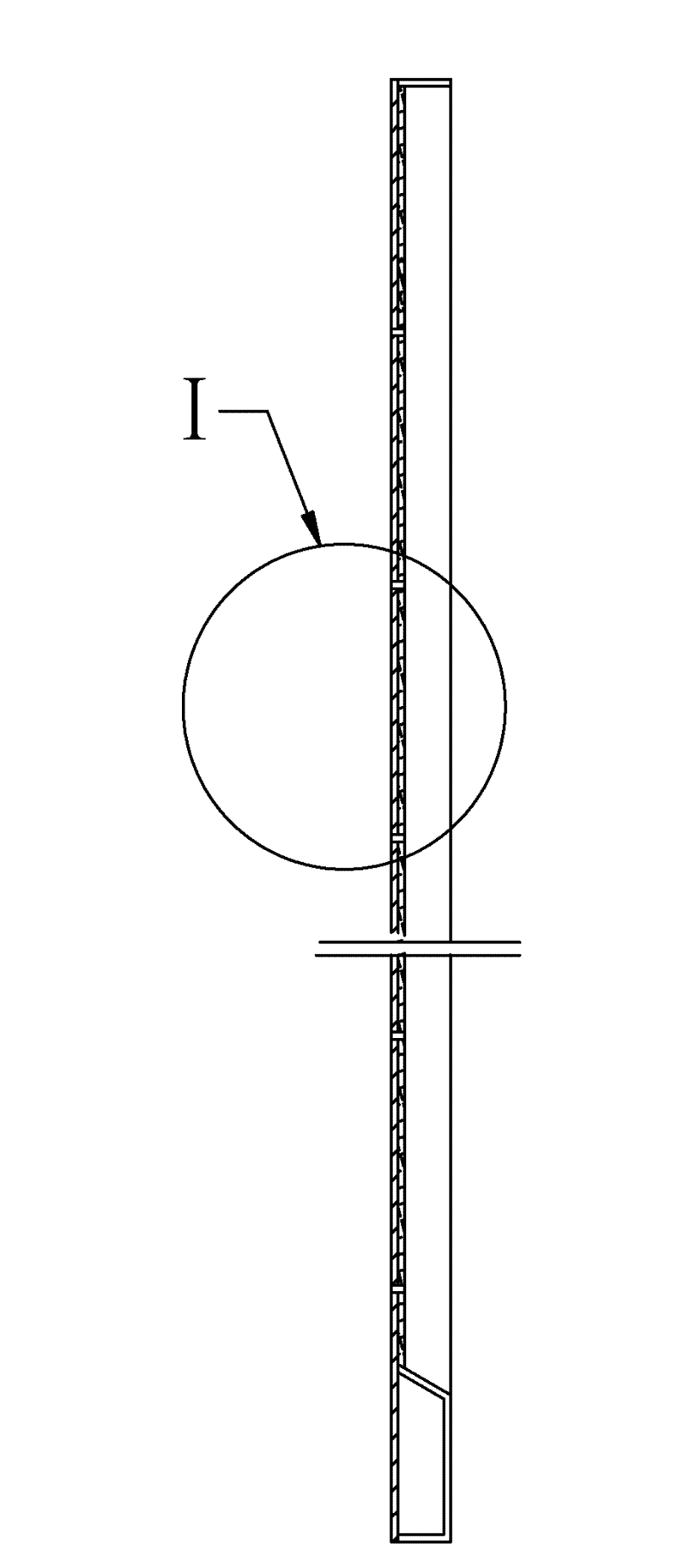

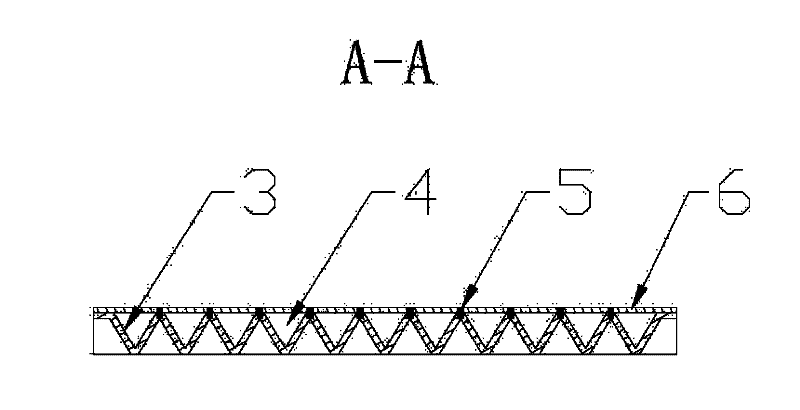

[0046] See attached figure 1 , 2 , 3, 4. The single-sided corrugated plate type pulsating heat pipe of the present invention includes a bottom plate 6, a wave plate 3, and a first communication cavity 1, and is characterized in that: the bottom plate 6 is a flat metal plate; one end of the bottom plate 6 is provided with a The first communication cavity 1 connected; the wave plate 3 is a curved plate formed by a periodic zigzag shape; the baffle plate is a flat metal plate; the two ends along the extending direction of the waves of the wave plate 3 and the The bottom plate 6 is sealed and connected, one end perpendicular to the extending direction of the wave of the wave plate 3 is sealed and connected with the first communication chamber 1, and the other end is sealed and connected with the bottom plate 6; the wave plate 3 is connected between two adjacent troughs A plurality of pulsating channels 4 perpendicular to the extension direction of the wave plate waves are formed...

Embodiment 2

[0049] See attached Figure 5 , 6 , the single-sided corrugated plate type pulsating heat pipe of the present invention includes a bottom plate 6, a wave plate 3, a first communication cavity 1, and a second communication cavity 2, and it is characterized in that: the bottom plate 6 is a plane metal plate; There is a first communication cavity 1 and a second communication cavity 2 that are sealed and connected with the bottom plate 6, and the wave plate 3 is a curved plate formed by a periodic zigzag shape; along the extension direction of the waves of the wave plate 3 Both ends are in sealing connection with the bottom plate 6, one end perpendicular to the extending direction of the waves of the wave plate 3 is in sealing connection with the first communication cavity 1, and the other end is in sealing connection with the second communication cavity 2, and the wave A plurality of pulsating channels 4 perpendicular to the extension direction of the waves of the wave plate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com