Sprue bush and manufacturing method therefor

A manufacturing method and runner technology, which are applied in the directions of additive manufacturing, process efficiency improvement, energy efficiency improvement, etc., can solve the problems of time increase, difficult cooling and solidification, and difficult cooling and solidification of molten resin raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

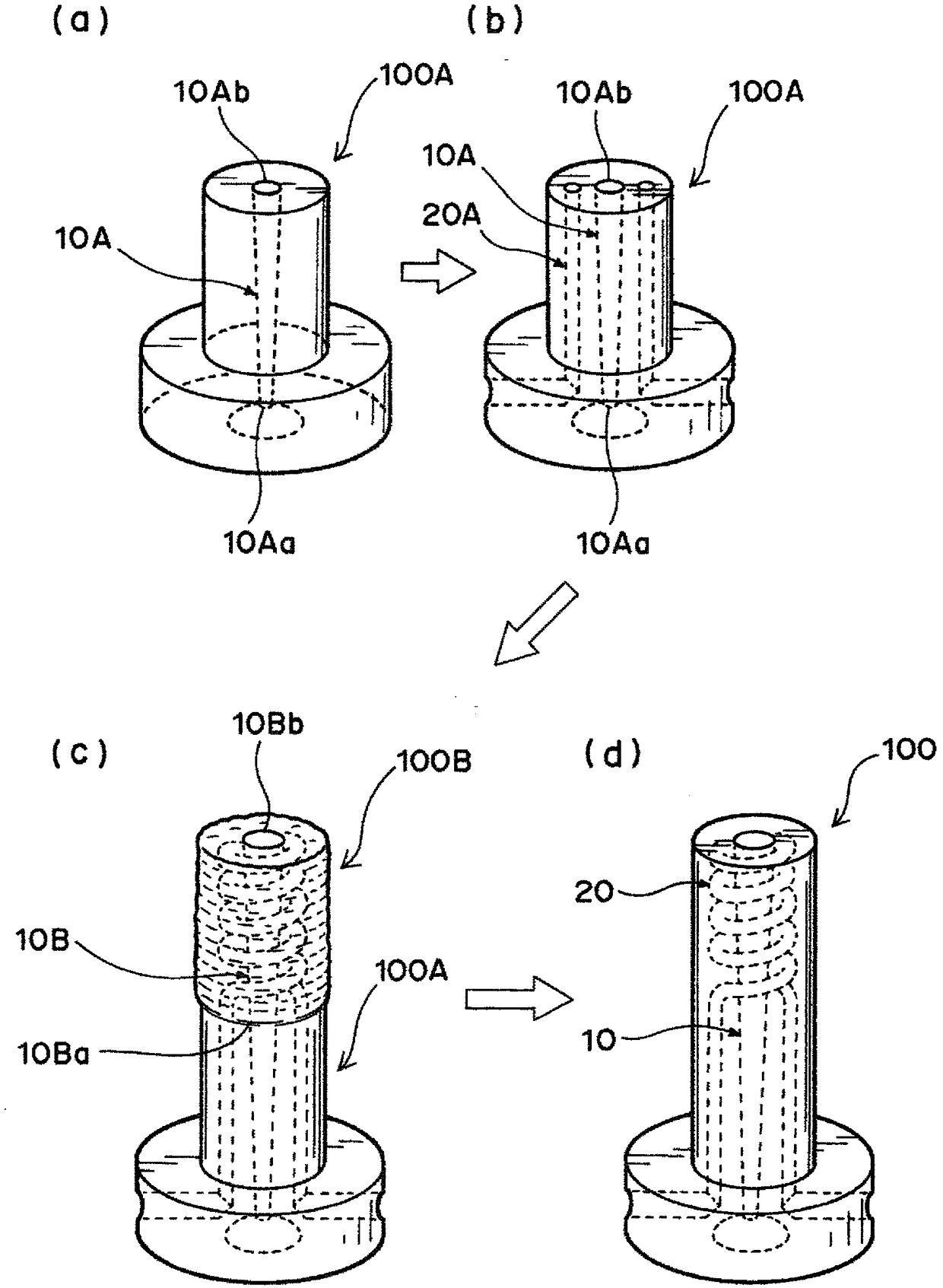

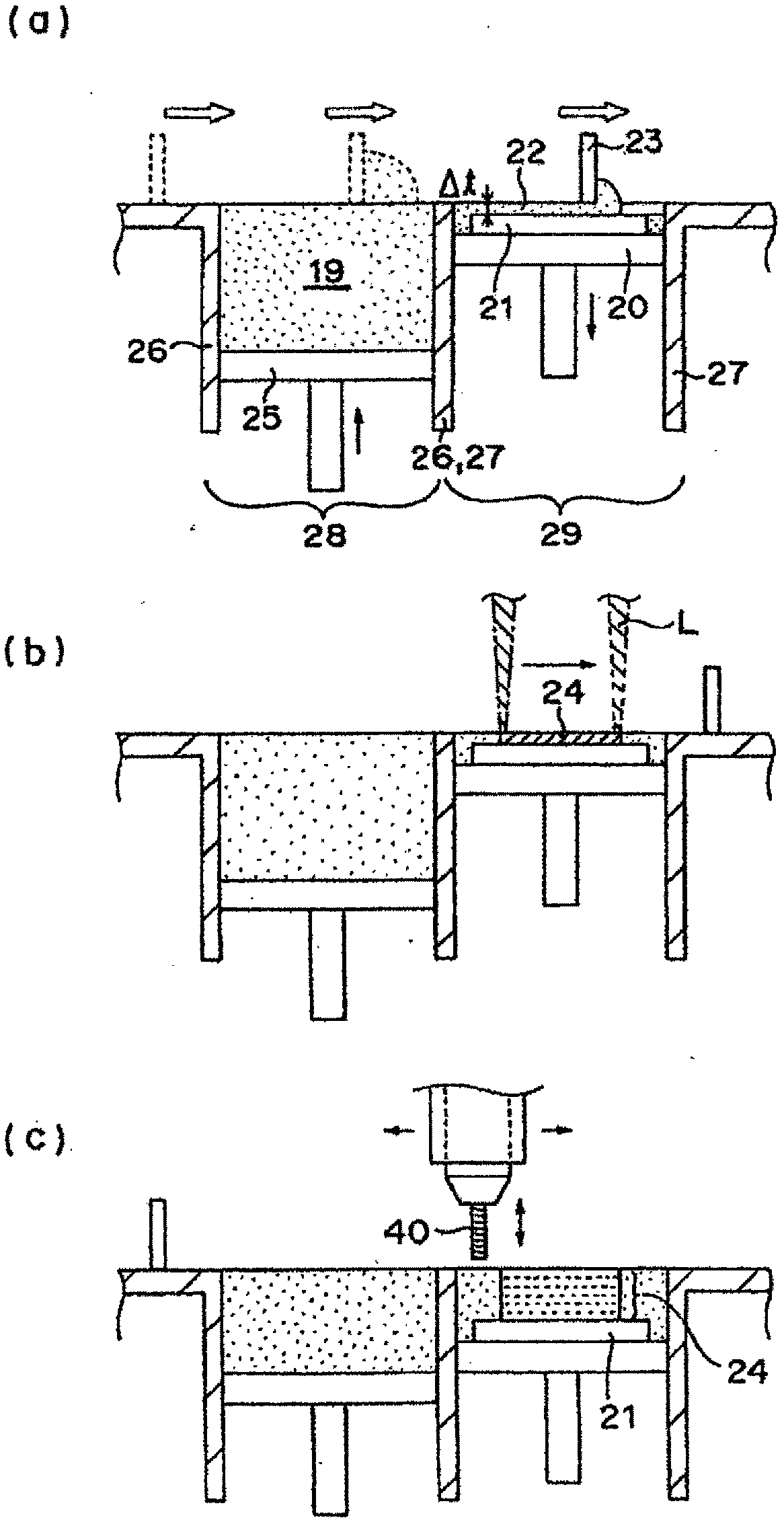

[0039] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings. The shape and size of each element in the drawings are merely examples, and do not reflect actual shapes and sizes.

[0040] The present invention is based on the technical idea of constituting the finally obtained sprue sleeve by at least two parts (base part and molding part). The "base" mentioned here essentially refers to the existing sprue bushing. Since the base is essentially an existing sprue bushing, the base can be used as a part for injection molding without providing another part (molded part) on the base main body. Nevertheless, the present invention is characterized in that the finally obtained sprue sleeve is intentionally formed by at least two parts (base and profile).

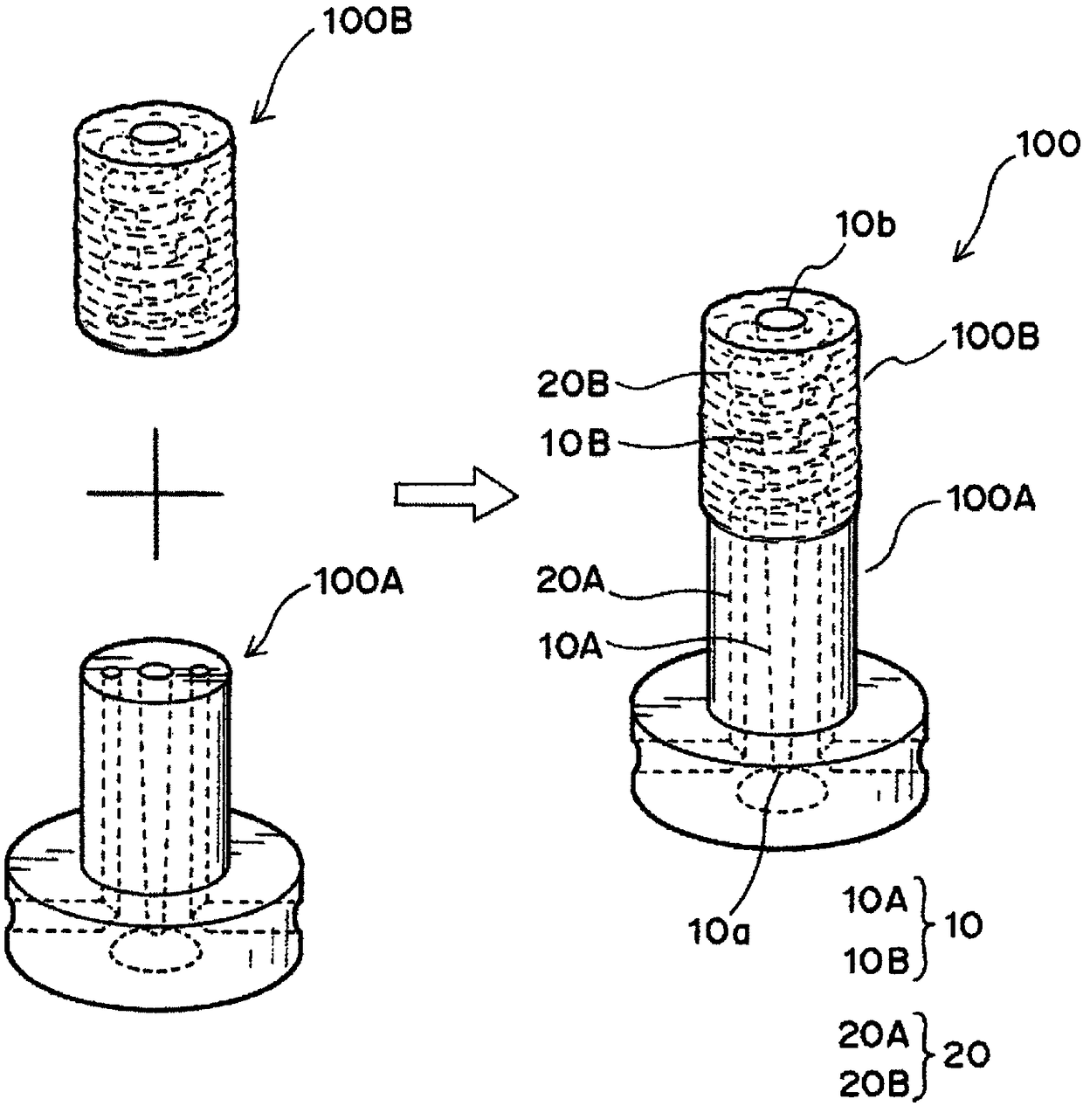

[0041] Such as figure 1 As shown, the sprue bushing 100 according to one embodiment of the present invention can be obtained by combining a base portion 100A and a moldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com