Method for determining a filling quantity

A filling volume, purpose technology, applied in non-mechanical driven clutches, clutches, fluid driven clutches, etc., can solve problems such as injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

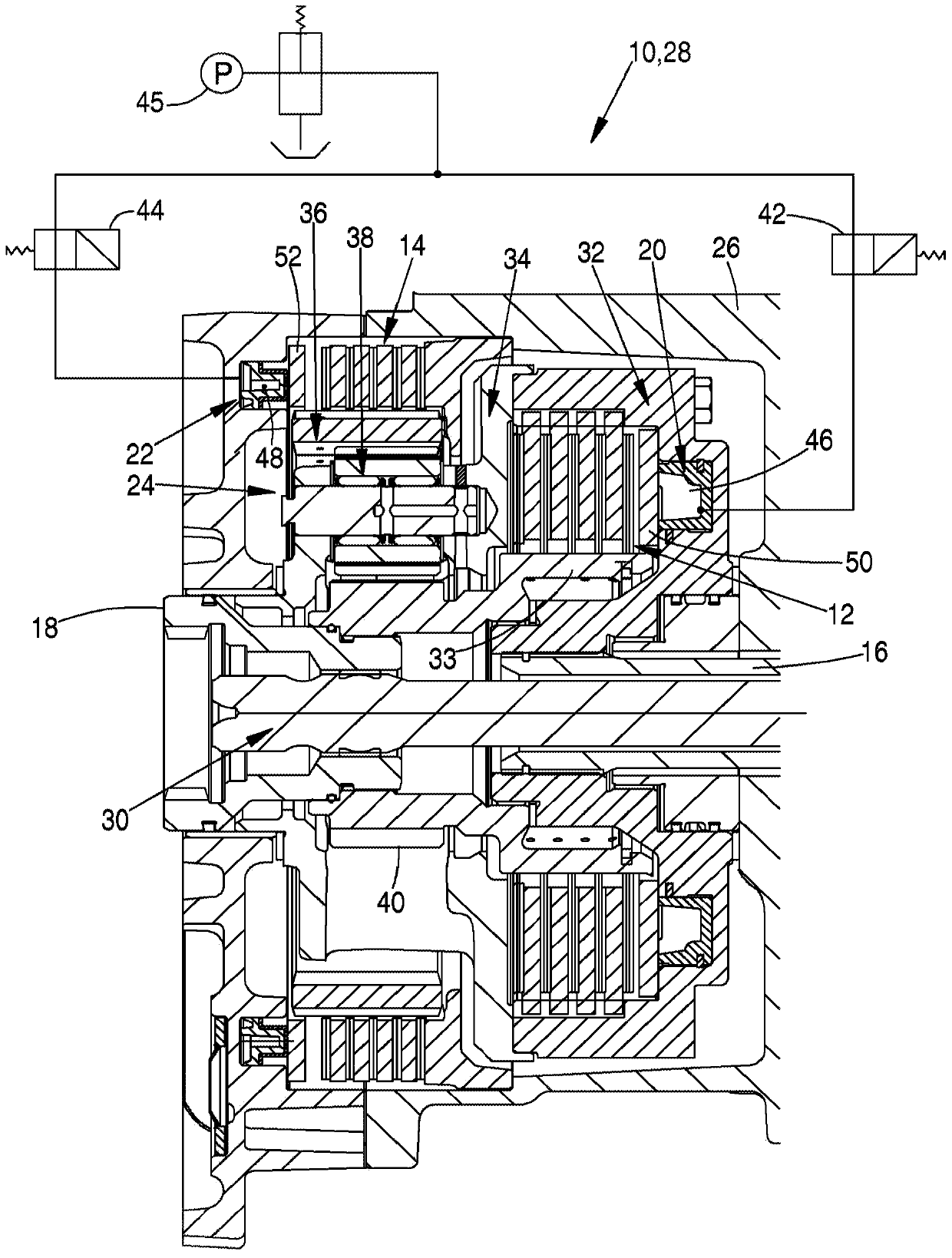

[0019] figure 1 A clutch device 10 of an agricultural utility vehicle is shown, which is designed as a reversing unit 28 and is arranged in a housing 26 . Both the input shaft 16 and the output shaft 18 are designed as hollow shafts. A shaft 30 , not described in further detail, runs inside the input shaft 16 and the output shaft 18 for example for driving a power take-off shaft of a utility vehicle.

[0020] The input shaft 16 is connectable in driving engagement with the output shaft 18 via a forward clutch 12 such that both shafts 16 , 18 have the same direction of rotation. The forward clutch 12 is here designed as a multiplate clutch. The outer plate support 32 is connected to a planetary support 34 of a transmission stage 24 designed as a double planetary gearing. The hollow gear 36 of the double planetary gear can be locked relative to the housing 26 via the reverse clutch 14 (also called reverse brake). The reverse clutch is also designed as a multi-plate clutch. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com