Chiller or heat pump with a falling film evaporator and horizontal oil separator

A technology of oil separator and heat pump, which is applied in the field of refrigerator or heat pump with falling film evaporator and horizontal oil separator, which can solve the problems of destruction, expensive, increased damage filter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

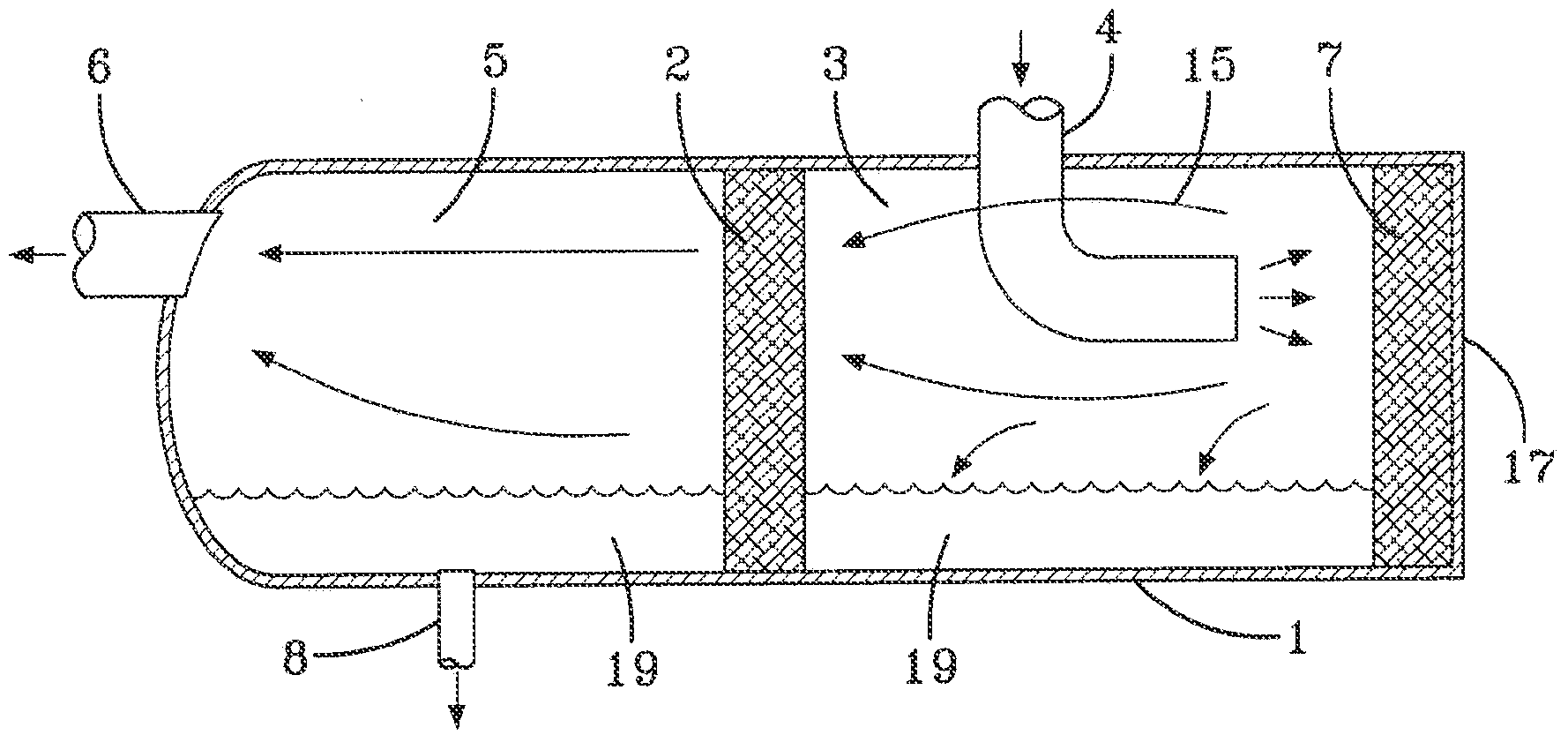

[0027] figure 2 A horizontal vessel 1 is shown with a filter mat 2 which divides the vessel longitudinally into two spaces: a main space 3 with an inlet 4 to receive discharge from the compressor; and a secondary space 5 with an outlet 6 communicates with an inlet of a condenser (not shown). In an example embodiment, the inlet 4 receives the compressor discharge, in which the gas and oil mixture 15 entering the separator vessel 1 may be arranged for in the main space 3 at one end of the vessel 1 Provides shock separation. Furthermore, a second filter mat 7 may be arranged on or near the end 17 of the container 1 where the impact occurs, to limit liquid re-entrainment of the gas discharged from the compressor after it collides with the end of the container.

[0028] In this arrangement, as figure 2 As further shown, the oil separated from the gas is allowed to move freely from the primary space 3 to the secondary space 5 . In one embodiment, the filter mat 2 is fitted acros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com