Detachable prong adjusting tool

A detachable and fork-tooth technology, applied in the direction of lifting devices, etc., can solve the problems of placing items in predetermined positions, being unable to use forklifts, and reducing production efficiency, so as to improve utilization rate, reduce labor cost input, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] The reference signs and components involved in the accompanying drawings are as follows:

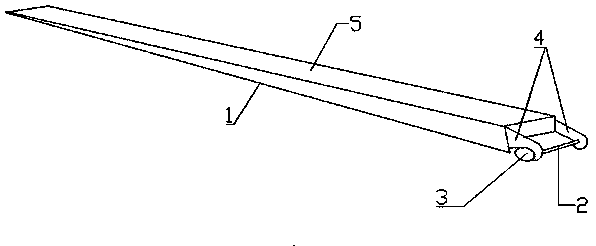

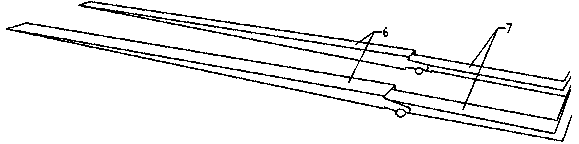

[0017] 1. Bottom plate 2. Fixed pin 3. Lock nut 4. Fixed ear plate

[0018] 5. U-shaped groove 6. Fork cover 7. Fork tines

[0019] as attached figure 1 And attached figure 2 As shown, a detachable fork tine adjustment tooling, including a fork cover 6. The fork cover 6 is welded by the bottom plate 1 and the U-shaped groove 5, and the fork cover 6 has the same shape as the fork tine 7 of the forklift, and can be set on the fork tine 7 and completely encase the fork truck tine 7 , and be fixed on the fork tine 7 roots in the form of a bolt. The length of described pallet fork cover 6 is 2500mm, and width is 174mm, and the height of pallet fork cover 6 opening ends is 95mm. The open end of the fork sleeve 6 is welded with two f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap