Yarn leading device for flat knitting machine

A technology of threading and flat knitting machines, applied in textiles and papermaking, weft knitting, knitting, etc., can solve problems such as easy thread breakage, low labor efficiency, and machine alarms, and achieve the effect of changing structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

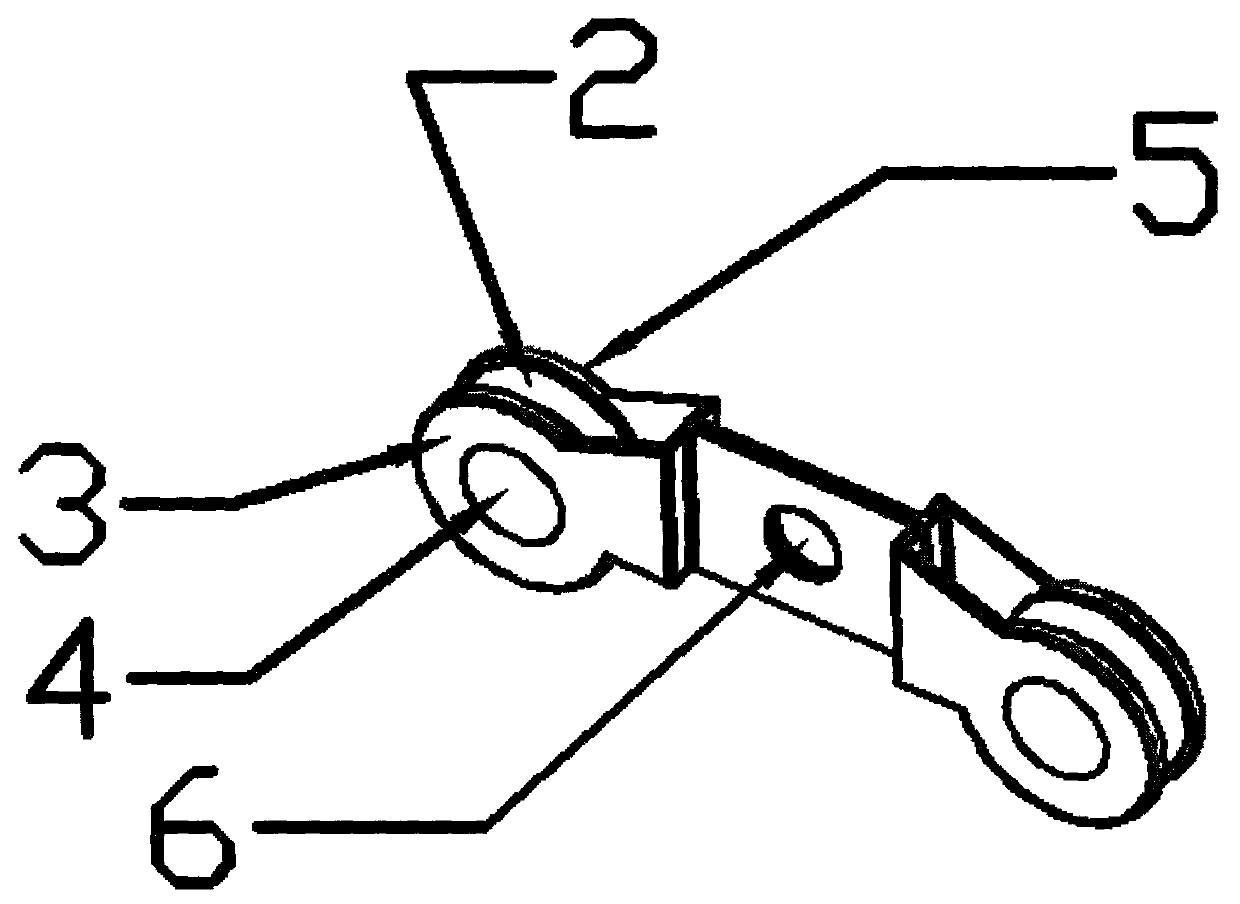

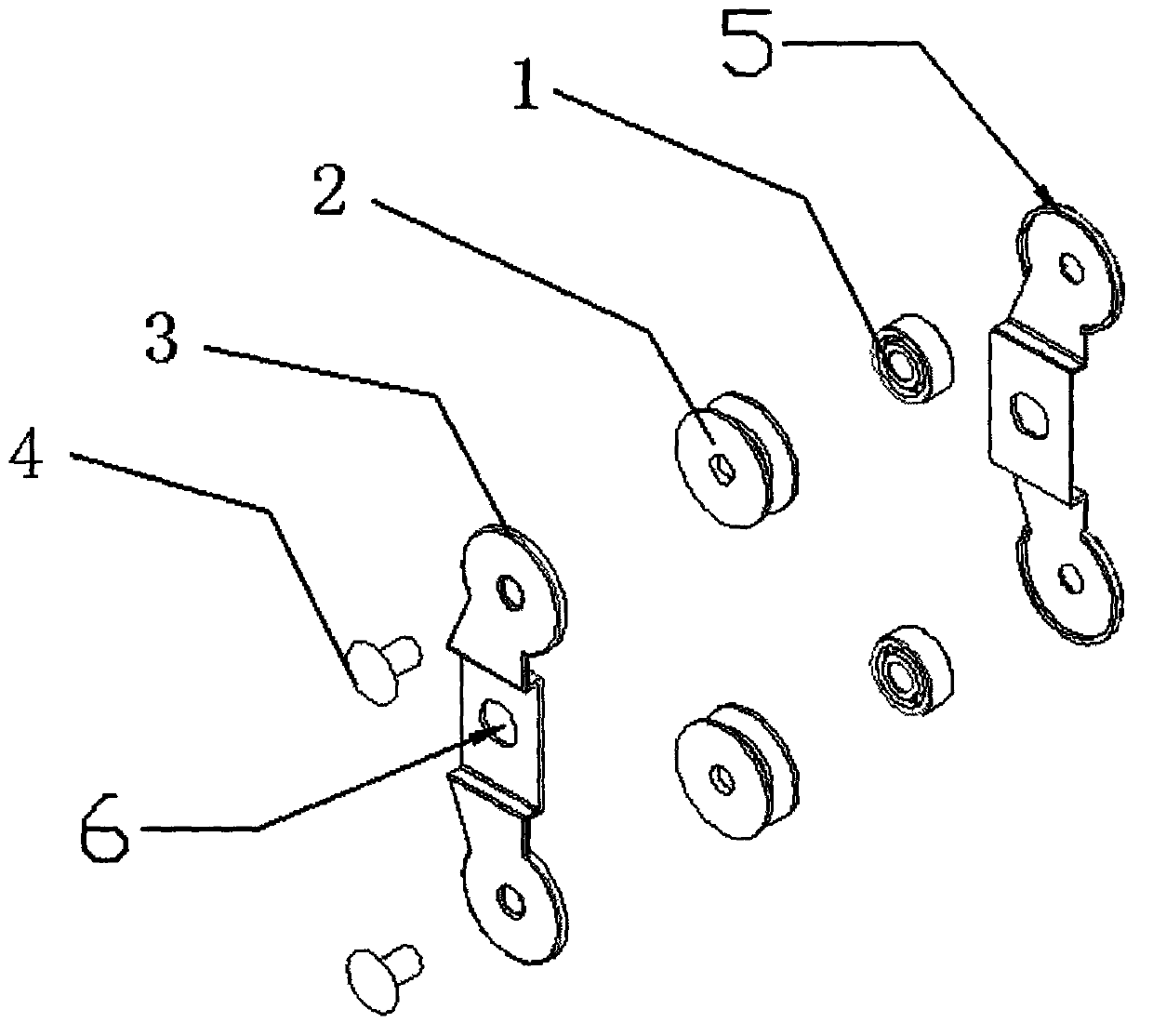

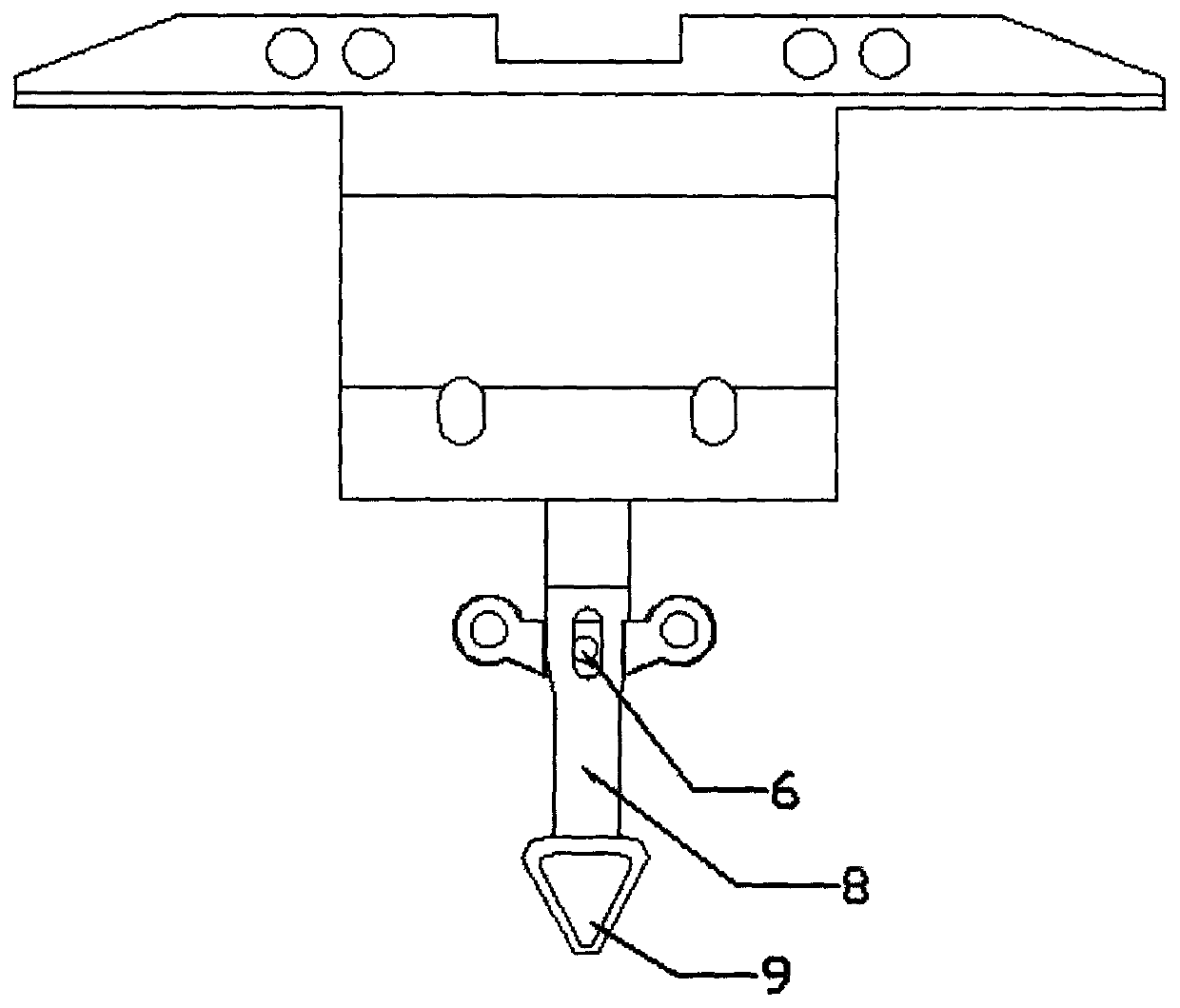

[0009] A lead wire device of a flat knitting machine comprises a bearing (1), a roller (2), a bracket one (3), a bracket two (5), and a pin (4); the bearing (1) is installed in the roller (2); Described roller (2) is installed on support one (3) and support two (5) two ends, and pin (4) is fixed by riveting support one (3), roller (2), support two (5); Support one (3), support two (5) are fixed on the flat knitting machine yarn feeder (8) by fixing hole (6), described support one (3), support two (5) two ends have surrounding rollers (2 ), the two ends of the support one (3) and the two ends of the support two (5) are concave and circular and are precisely combined with the roller (2), so that the yarn cannot be entangled; the roller (2) ) is designed with a U-shaped smooth wire groove, which is finely polished and uninterrupted; the yarn reaches the needle plate of the flat knitting machine through the roller and the yarn feeder opening (9) to achieve the function of leading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com