Fireproof and insulating light composite glass magnesium board and its preparation method

A composite glass-magnesium board, refractory and thermal insulation technology, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of no economic value, waste of resources, narrow application range, etc., to achieve sustainable development, avoid manual errors, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

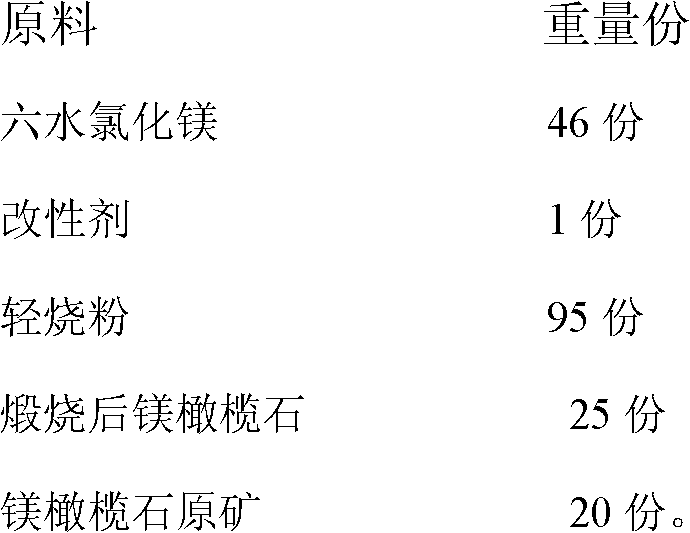

[0069] A fire-resistant and heat-preserving lightweight composite glass magnesium board, which is prepared from the following raw materials in parts by weight:

[0070]

[0071]

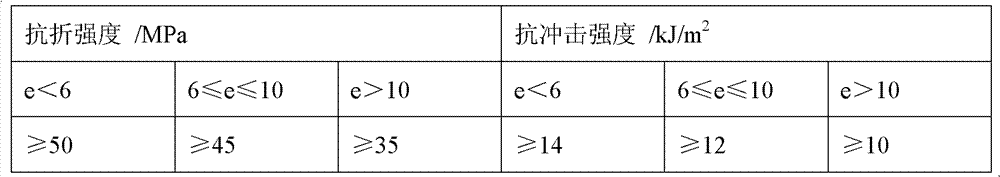

[0072] A method for preparing a refractory and heat-insulating lightweight composite glass magnesium board, the steps of which are:

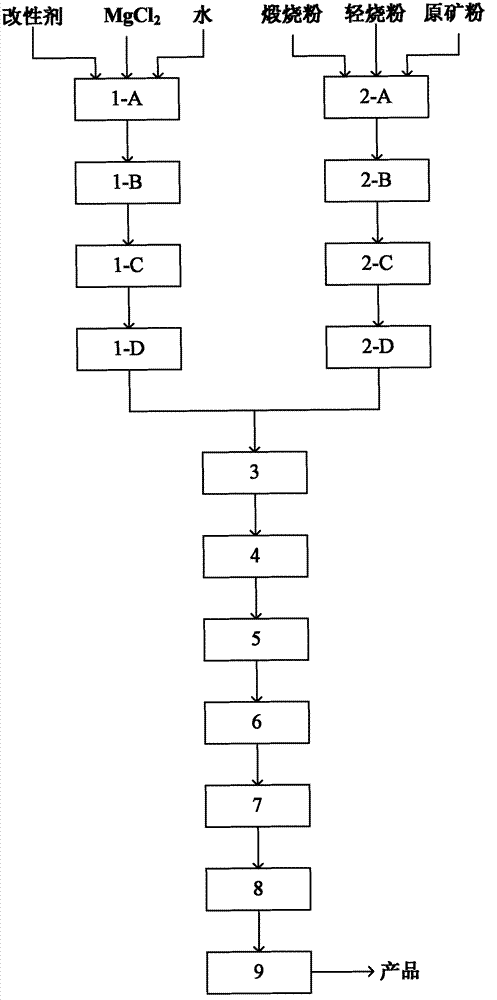

[0073] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0074] 1. Use 50 parts of magnesium chloride hexahydrate (magnesium chloride content ≥ 44%) in Golmud, Qinghai, measure (1-A), dissolve in 50 parts of water (1-B, 1-C), measure its Baume degree, and prepare into a 22% liquid (1-D), and then add modifier phosphoric acid or sodium tripolyphosphate or sulfate or aluminate to form a liquid mixture, measure the physical properties of the liquid, and measure it. Grind forsterite raw ore powder and calcined ore powder until its fineness reaches 0.08mm square hole sieve residue is less than 10%, of which forste...

Embodiment 2

[0094] A fire-resistant and heat-preserving lightweight composite glass magnesium board, which is prepared from the following raw materials in parts by weight:

[0095]

[0096] A method for preparing a refractory and heat-insulating lightweight composite glass magnesium board, the steps of which are:

[0097] 1. Use magnesium chloride hexahydrate (magnesium chloride content ≥ 44%) (step 1-A) from Golmud, Qinghai, dissolve it in a dissolution tank, measure its Baume degree, prepare 22% liquid (1-B), and then add modified Phosphoric acid or sodium tripolyphosphate or sulfate or aluminate is used to form a liquid mixture, and the physical properties of the liquid are measured for metering (steps 1-C, 1-D).

[0098] 2. Grinding the calcined ore powder until its fineness reaches 0.08mm square hole sieve residue is less than 10%, wherein the MgO content in the calcined ore powder is ≥40%. Weigh the calcined ore powder and lightly calcined powder (with MgO content of 80-85%, and...

Embodiment 3

[0119] A fire-resistant and heat-preserving lightweight composite glass magnesium board, which is prepared from the following raw materials in parts by weight:

[0120]

[0121] A method for preparing a refractory and heat-insulating lightweight composite glass magnesium board, the steps of which are:

[0122] 1. Use magnesium chloride hexahydrate (magnesium chloride content ≥ 44%) (step 1-A) in Golmud, Qinghai, dissolve in a dissolving tank, measure the Baume degree of the solution, prepare a 22% solution (step 1-B), and then add One of the modifier phosphoric acid or sodium tripolyphosphate or sulfate or aluminate forms a liquid mixture, and the physical properties of the liquid are measured for metering (steps 1-C, 1-D).

[0123] 2. Grind the forsterite raw ore powder until its fineness reaches a 0.08mm square hole sieve residue of less than 10%, wherein the MgO content in the raw ore powder is ≥36%. Weigh forsterite raw ore powder and lightly burned powder (MgO content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com