Preparation method of metal protective coating

A metal protection and coating technology, which is applied in coatings, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as structural defects and complex processes of micro-arc oxidation coatings that cannot be fundamentally solved, and achieve structural changes Defects, simple operation, and the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

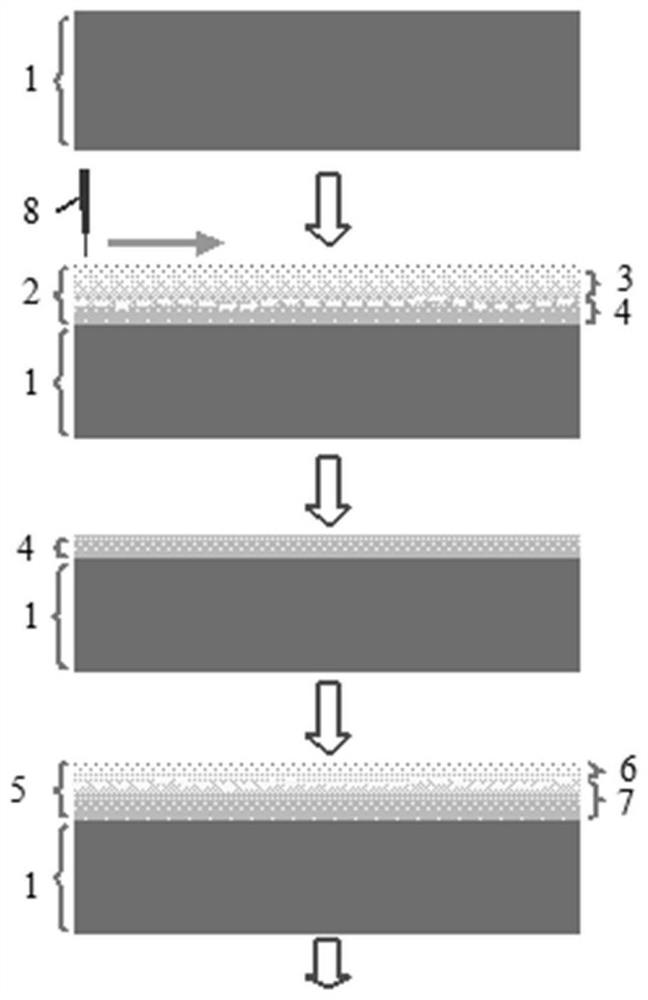

[0034] This embodiment provides a kind of method that adopts micro-arc oxidation technology to prepare metal protective coating, such as figure 1 shown, including the following steps:

[0035] (1) AZ31 magnesium alloy substrate 1 is subjected to a conventional micro-arc oxidation in the electrolyte;

[0036] The composition of the electrolyte is: 20g / L NaSiO 3 9H 2 O, 2g / L KOH, 2g / L NaF, 1g / L NaVO 3 2H 2 O.

[0037] The operating conditions of micro-arc oxidation are: the power supply adopts bipolar pulse power supply, constant current mode, pulse frequency is 500Hz, duty cycle is 20%, and current density is 10A / dm 2 , the circulating water cooling temperature is 20°C, and the oxidation time is 15min.

[0038] After a conventional micro-arc oxidation treatment, a micro-arc oxidation coating 2 is obtained on the surface of the AZ31 magnesium alloy substrate 1; the micro-arc oxidation coating 2 is composed of an inner dense area 4 and an outer loose area 3;

[0039] Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com