One-way self-locking shear force connector for stacked beams

A self-locking, shear-resistant technology, applied in the direction of construction and building construction, can solve the problems of increasing the size of floor beams and ceiling beams, poor overall mechanical properties, and inapplicable seismic requirements, etc., to improve the stiffness of stacked beams , good overall mechanical properties, simple and reliable construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, a one-way self-locking type shear force connector for a stacking beam as an embodiment of the present invention will be described based on the drawings.

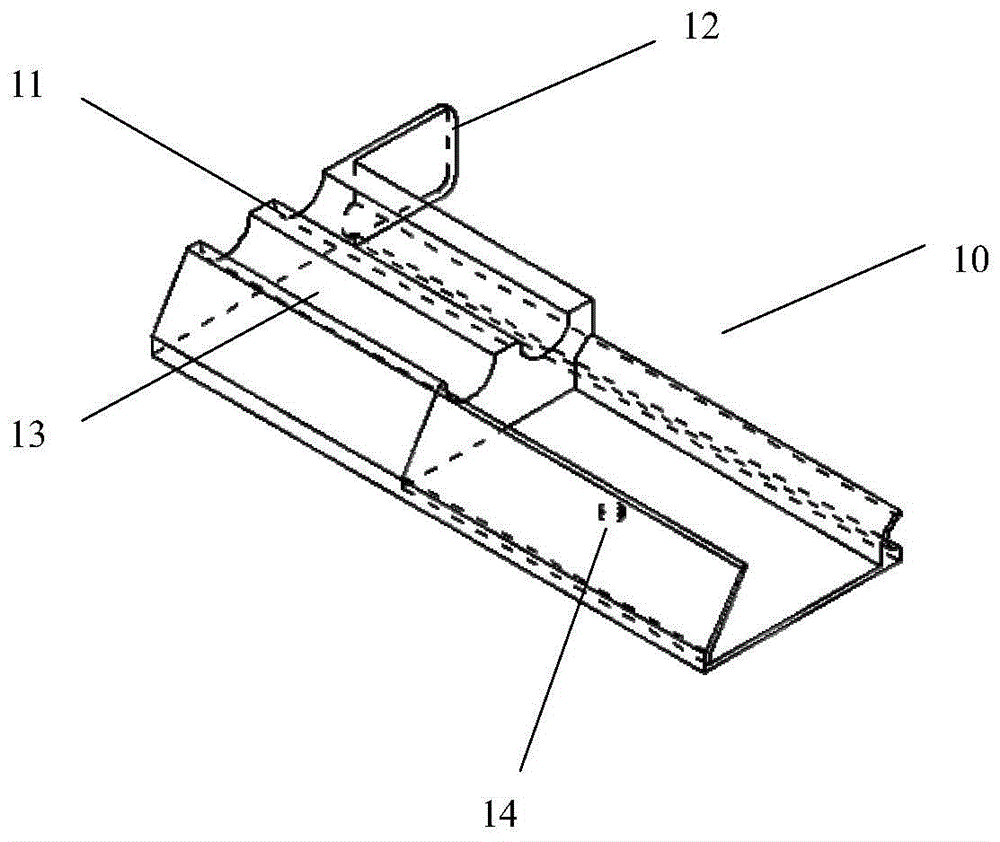

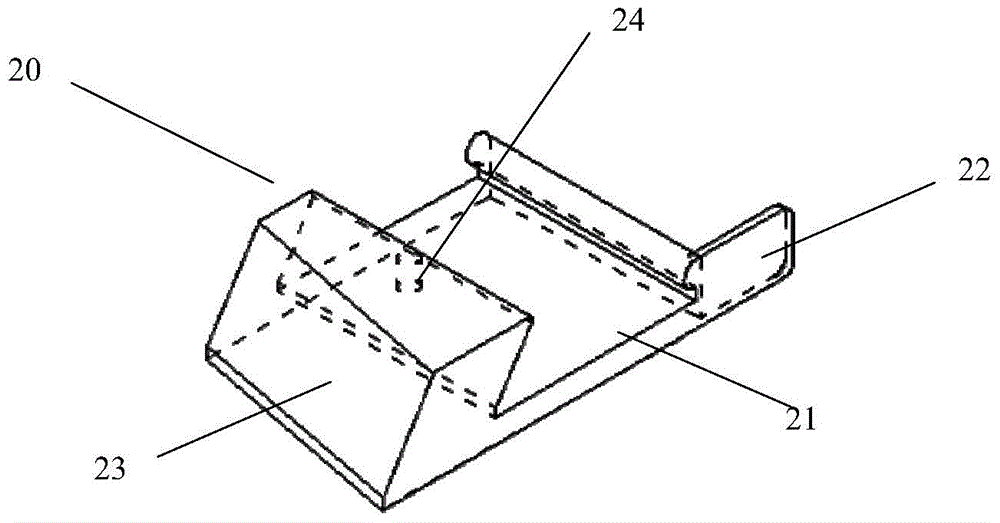

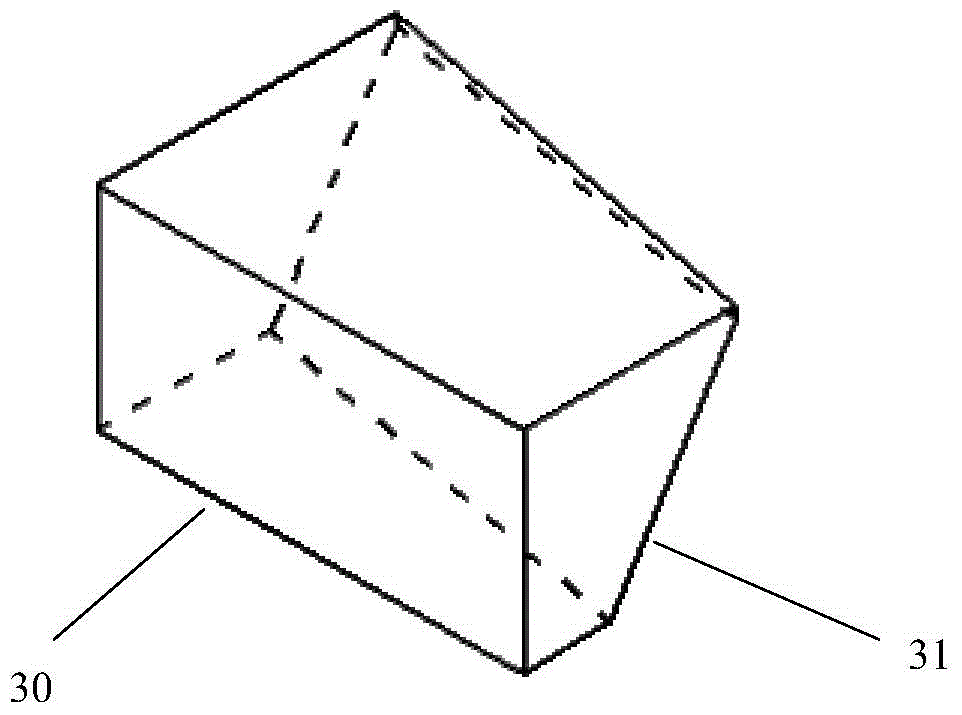

[0042] figure 1 It is a three-dimensional schematic diagram showing the fixed guide rail of the one-way self-locking shear force connector of the stacking beam. figure 2 It is a three-dimensional schematic diagram showing the sliding part of the one-way self-locking shear force connector of the stacking beam. image 3 It is a three-dimensional schematic diagram showing the fixed engaging block of the one-way self-locking shear force connector of the stacking beam. Figure 4 It is a schematic diagram showing the installation position of the one-way self-locking shear force connector of the stacking beam. Figure 5 It is a schematic diagram showing the installation direction of the one-way self-locking shear force connector of the stacking beam. Figure 6 It is a schematic perspective view showing a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com