A method of hoisting and transporting round stone columns with inner steel pipes

A technology of round stone pillars and inner steel pipes, which is applied to the field of inner steel pipe hoisting and transportation of round stone pillars, can solve problems such as breaking or pulling of round stone pillars, and breaking of round stone pillars, and achieves the effects of improving safety and reducing the probability of breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

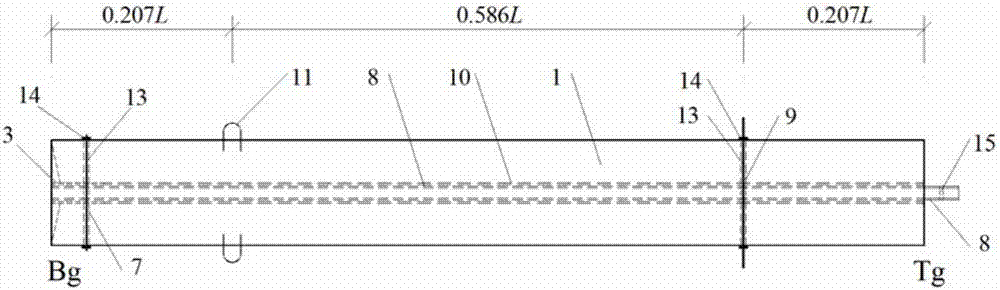

[0067] The present invention will be further described below in conjunction with drawings and embodiments.

[0068] This embodiment is to transport and hoist a round stone column with length L=10000mm, diameter D=750mm, and stone material is artificial marble. Allowable tensile stress of artificial marble [σ] = 8.0MPa, bulk density ρ = 0.0000238N / mm 3 .

[0069] First, determine whether the boulder column can be transported and hoisted by the method of the present invention through calculation:

[0070] According to the use conditions of the present invention, the method of the present invention can be used for transportation and hoisting.

[0071] Transport and hoist according to the following steps:

[0072] Step 1. Make a boulder column with lifting components

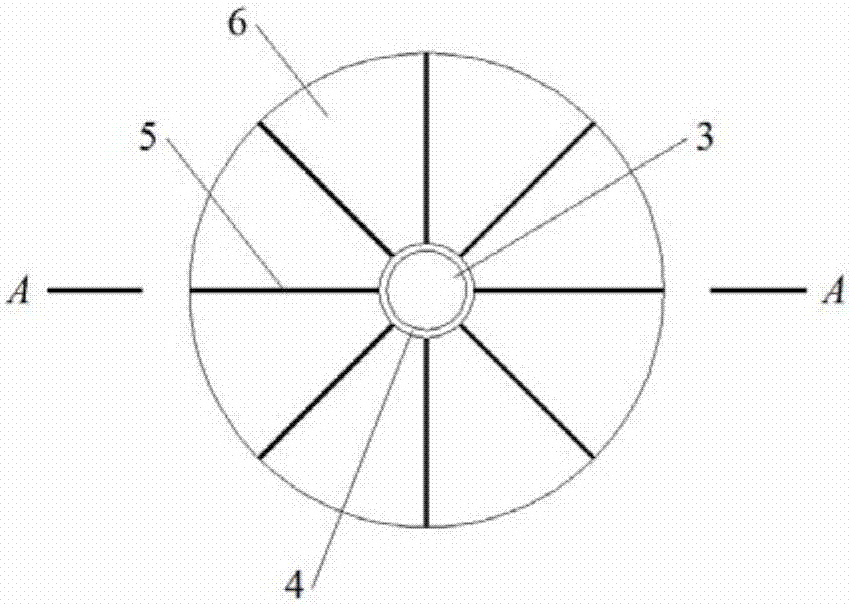

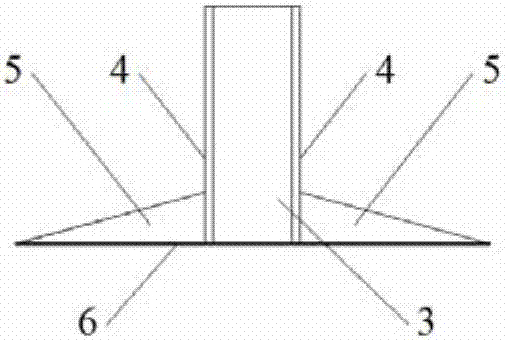

[0073] combine Figure 1 to Figure 3 , when using the template to make the round stone column 1, a hoisting assembly consisting of the bottom steel plate 3, the steel wire rope limit reinforcement 11, the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com