Pre-mixing device of continuous dough mixer

A technology of pre-mixing and kneading machine, which is applied in the direction of mixing/kneading with vertical installation tools, which can solve the problems of uneven mixing of mixed ingredients and water, affecting the processing quality of instant noodles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

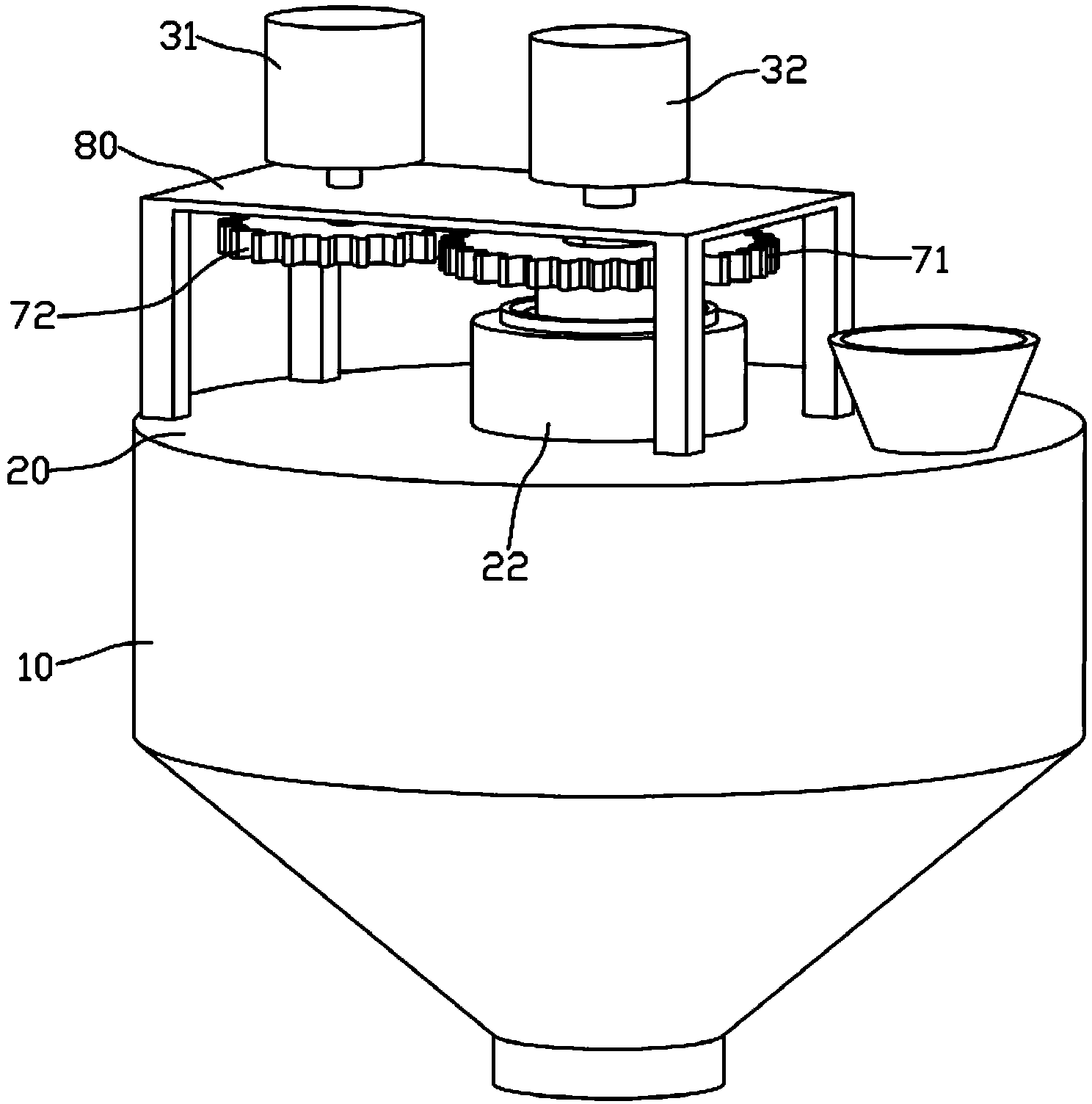

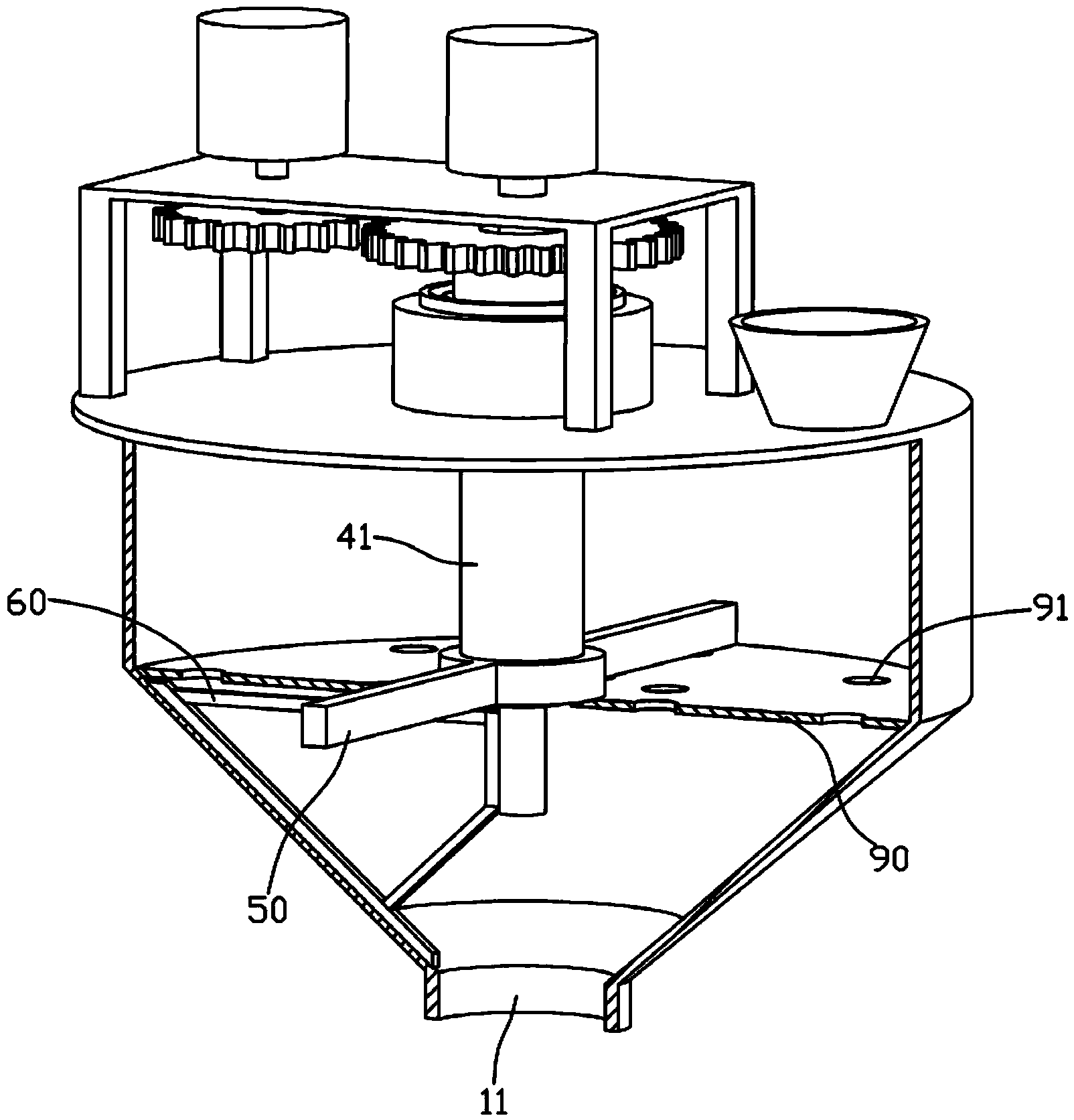

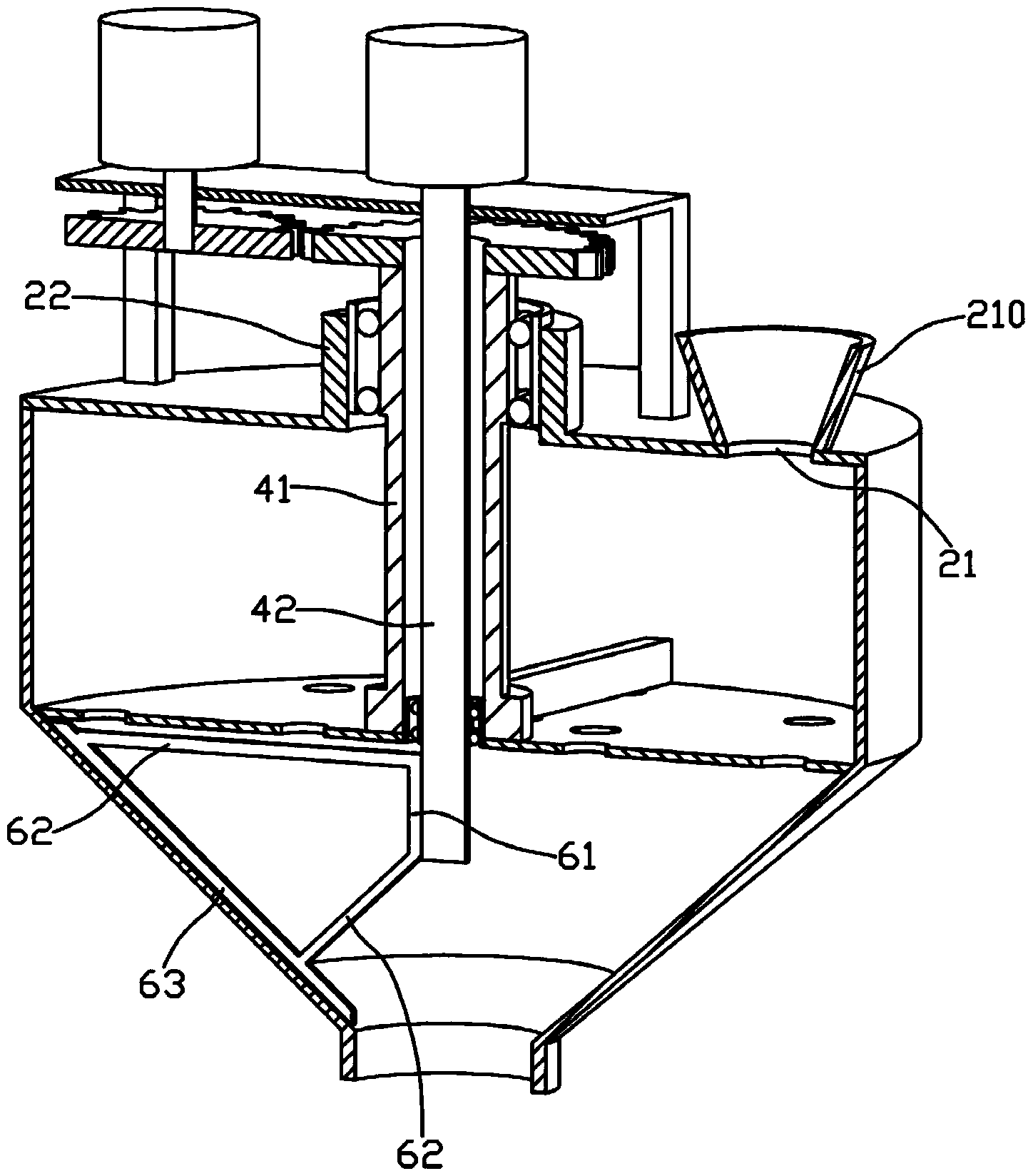

[0025] Such as figure 1 As shown, a pre-mixing device of a continuous dough mixer includes a mixing drum 10, a top cover 20 installed at one end of the mixing drum 10, a support plate 80 installed on the top cover 20, and a support plate installed on the support plate 80. Motor one 31, the driving gear 72 that is installed on the motor one 31 rotating shafts, the driven gear 71 that is installed on shaft one 41, described top cover 20 central places are provided with bearing seat 22, as image 3 As shown, the first shaft 41 is movably installed in the bearing housing 22 through bearings, the first shaft 41 is perpendicular to the top cover 20 and inserted into the mixing drum 10 . Such as figure 2 As shown, a scraper 50 is installed at the end of the first shaft 41 entering the mixing drum 10 , the scraper 50 is perpendicular to the first shaft 41 , and the free end of the scraper 50 is close to the inner wall of the cylindrical part of the mixing drum 10 .

[0026] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com