Automatic assembly device for angle adjuster disc spring of automobile seat

An automatic assembly device and car seat technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as loud noise, personal injury of assembly workers, and collapse of coil springs, etc., to achieve low noise and save energy. The effect of removing physical labor and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

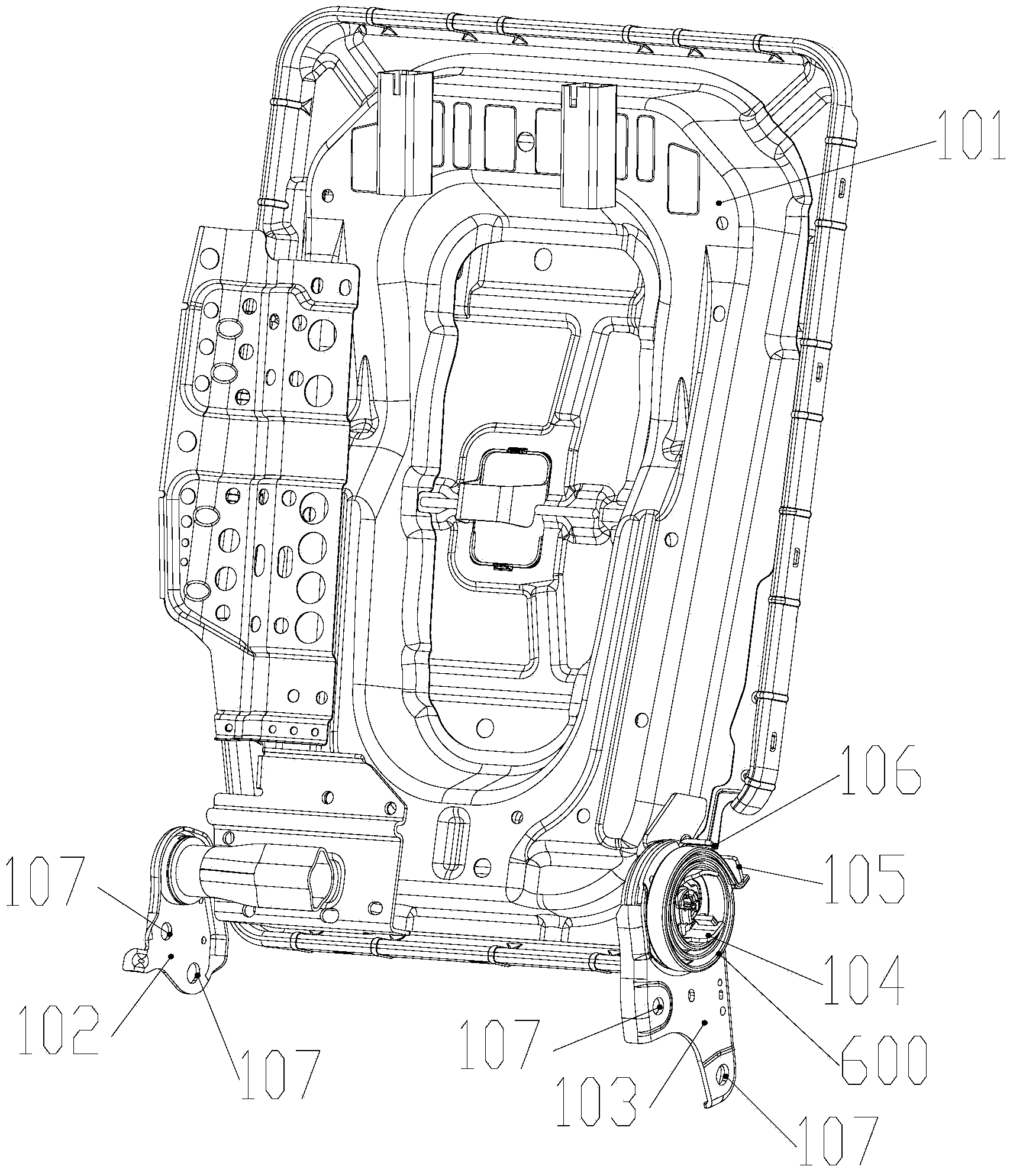

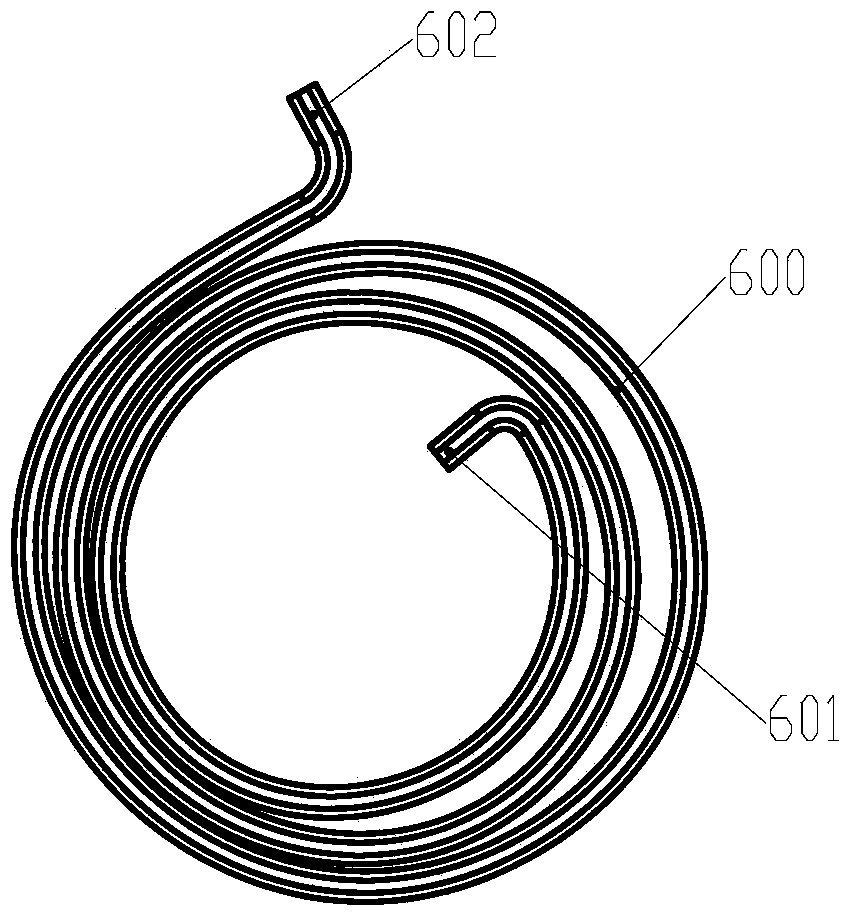

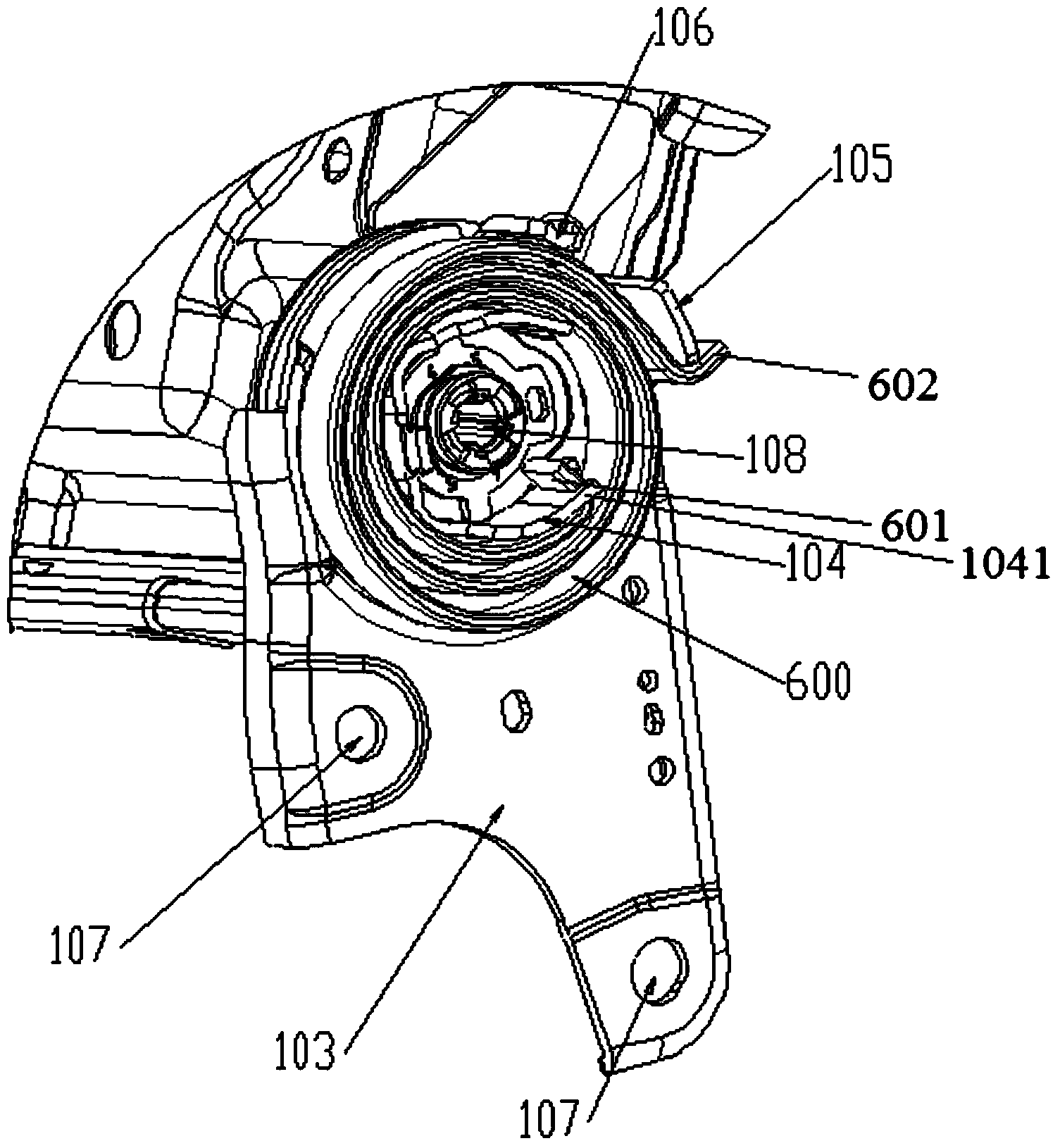

[0066] Such as Figure 1-3 As shown, in this embodiment, the seat back 100 of the automobile includes: a backrest body 101, a left ear plate 102 and a right ear plate 103 respectively located at the left and right ends of the lower part of the backrest body 101, and a coil spring arranged on the right ear plate 103 Inner card slot 104, coil spring outer support structure 105 and coil spring outer ring limiting structure 106, a plurality of positioning holes 107 arranged on the left ear plate 102 and the right ear plate 103 respectively (in this embodiment, left and right Two positioning holes 107 ) are respectively arranged on the ear plates 102 , 103 , and a backrest rotating shaft 108 passing through the right ear plate 103 vertically.

[0067] When the coil spring 600 is assembled in place on the seat back 100, it should be sleeved on the backr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com