Injection upper mould with cooling function and for CPU (Central Processing Unit) fan blade

A fan blade, injection molding technology, applied in the field of injection molding upper mold, can solve problems such as lowering the product qualification rate, and achieve the effects of convenient mold design, fast heating speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

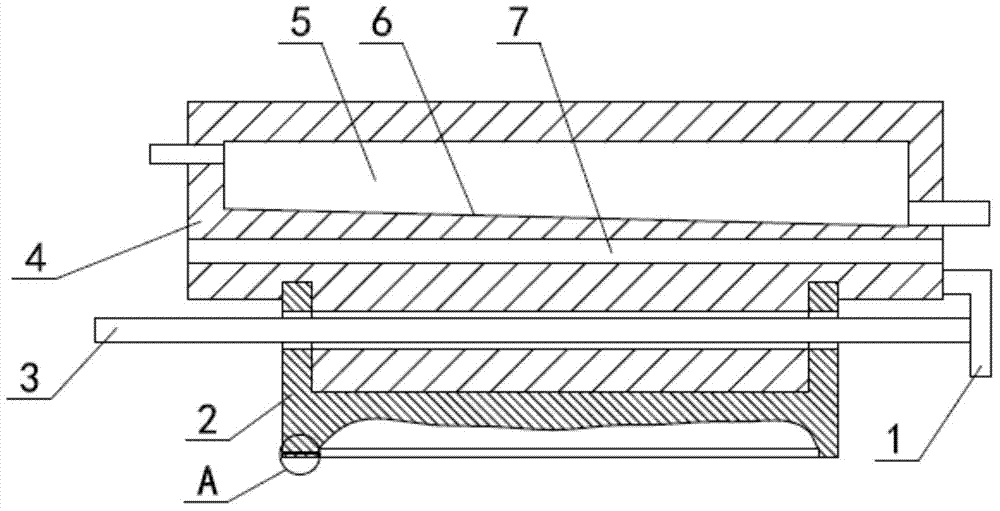

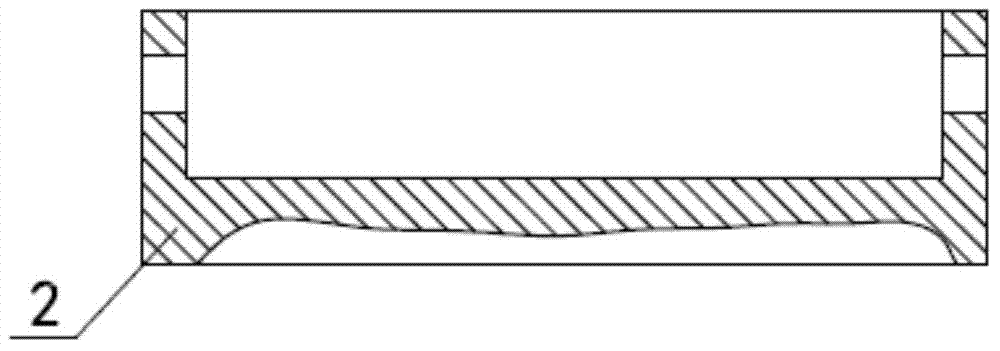

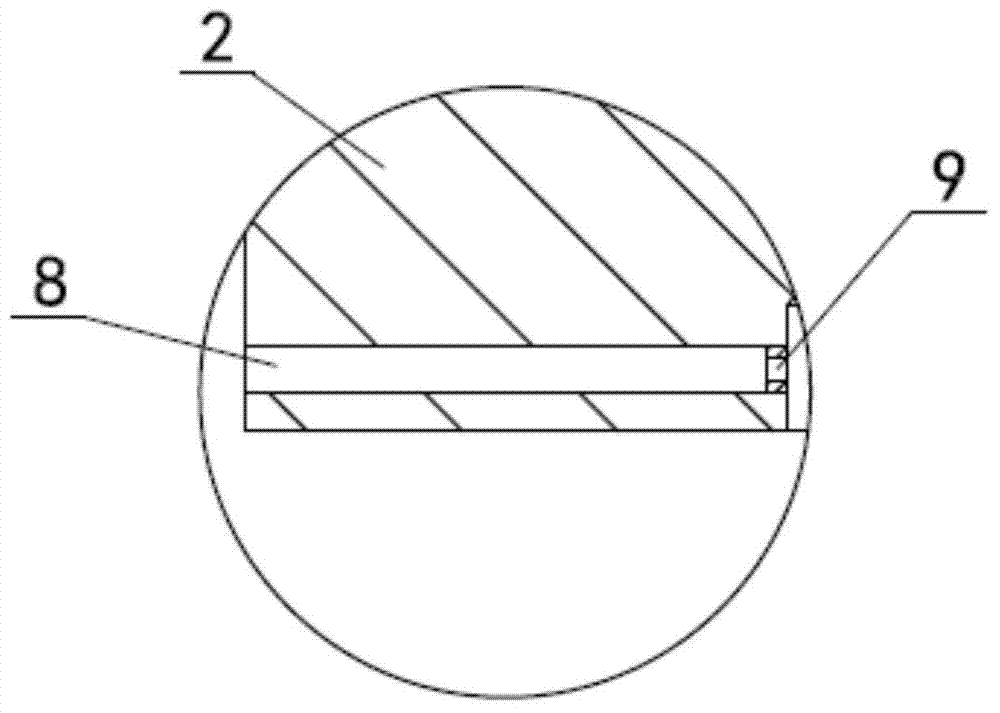

[0018] Such as figure 1 , figure 2 , image 3 As shown, the CPU fan blade is equipped with a cooled injection molding upper mold, including the upper mold body 2, the lower left part of the upper mold body 2 is horizontally provided with an injection molding channel 8, and a piece is provided on the upper part of the upper mold body 2 for heating the upper mold body 2. The heating aluminum block 4 is provided with a groove downward on the upper surface of the upper mold body 2, and the lower surface of the heating aluminum block 4 extends downward with a protrusion matching the groove. In the heating chamber 5 heated by steam, the heating aluminum block 4 on the left side of the heating chamber 5 is provided with a steam inlet, and the heating aluminum block 4 on the right side of the heating chamber 5 is provided with a steam outlet. The bottom surface of the heating chamber 5 is a left high On the lower right inclined surface 6, a cooling water chamber 7 is provided later...

Embodiment 2

[0022] This embodiment is changed on the basis of Embodiment 1, and the left exposed end of the connecting rod 3 is changed to 400 mm; the diameter of the connecting rod 3 is changed to 40 mm. Others are the same as embodiment one.

Embodiment 3

[0024] This embodiment is changed on the basis of Embodiment 1, and the left exposed end of the connecting rod 3 is changed to 500 mm; the diameter of the connecting rod 3 is changed to 50 mm. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com