System and method for automatic location assignment of wheels equipped with pressure sensors

A pressure sensor, equipped with technology, applied in the field of wheel position of the wheel, can solve the problem of adding hardware and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

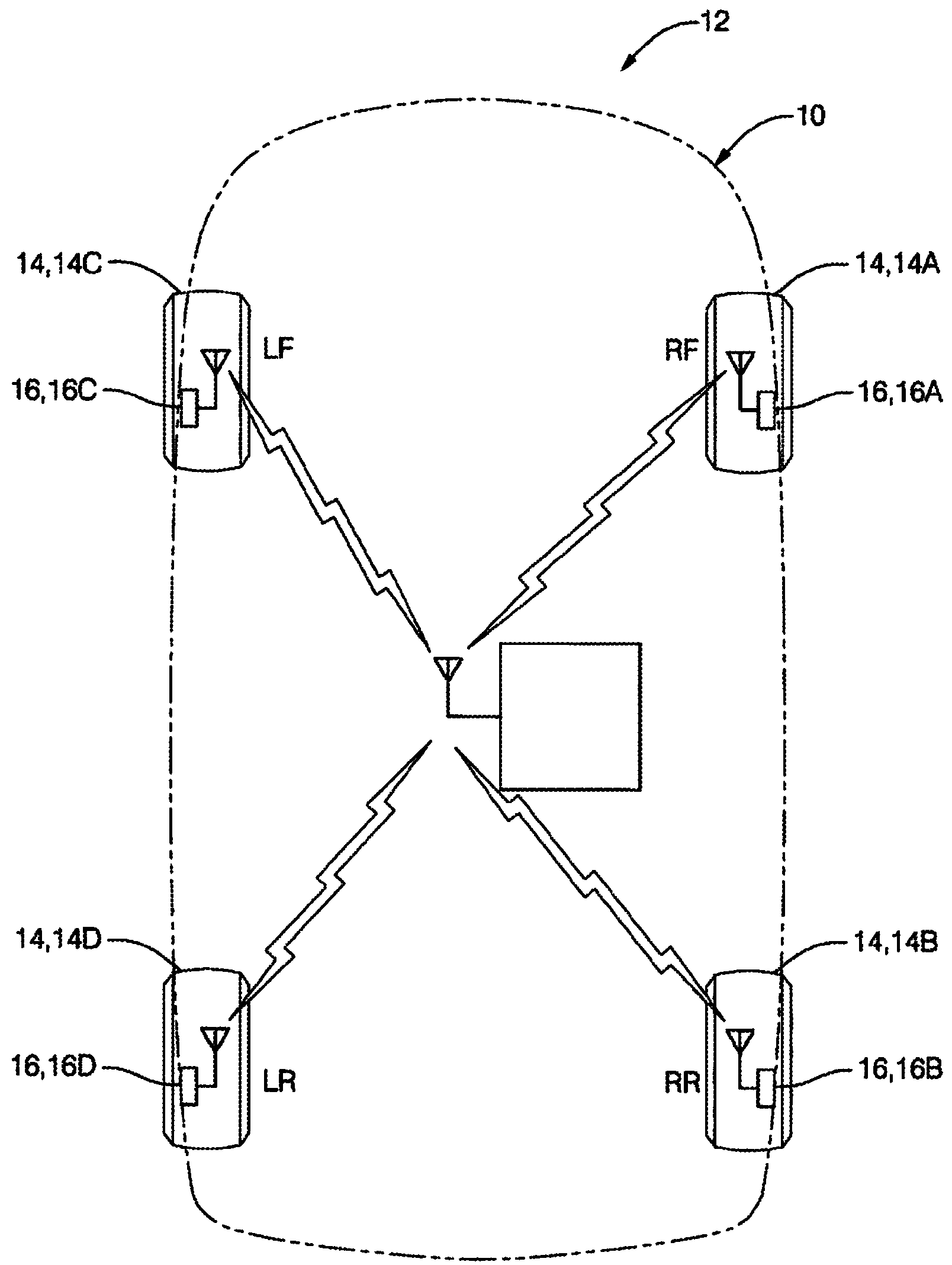

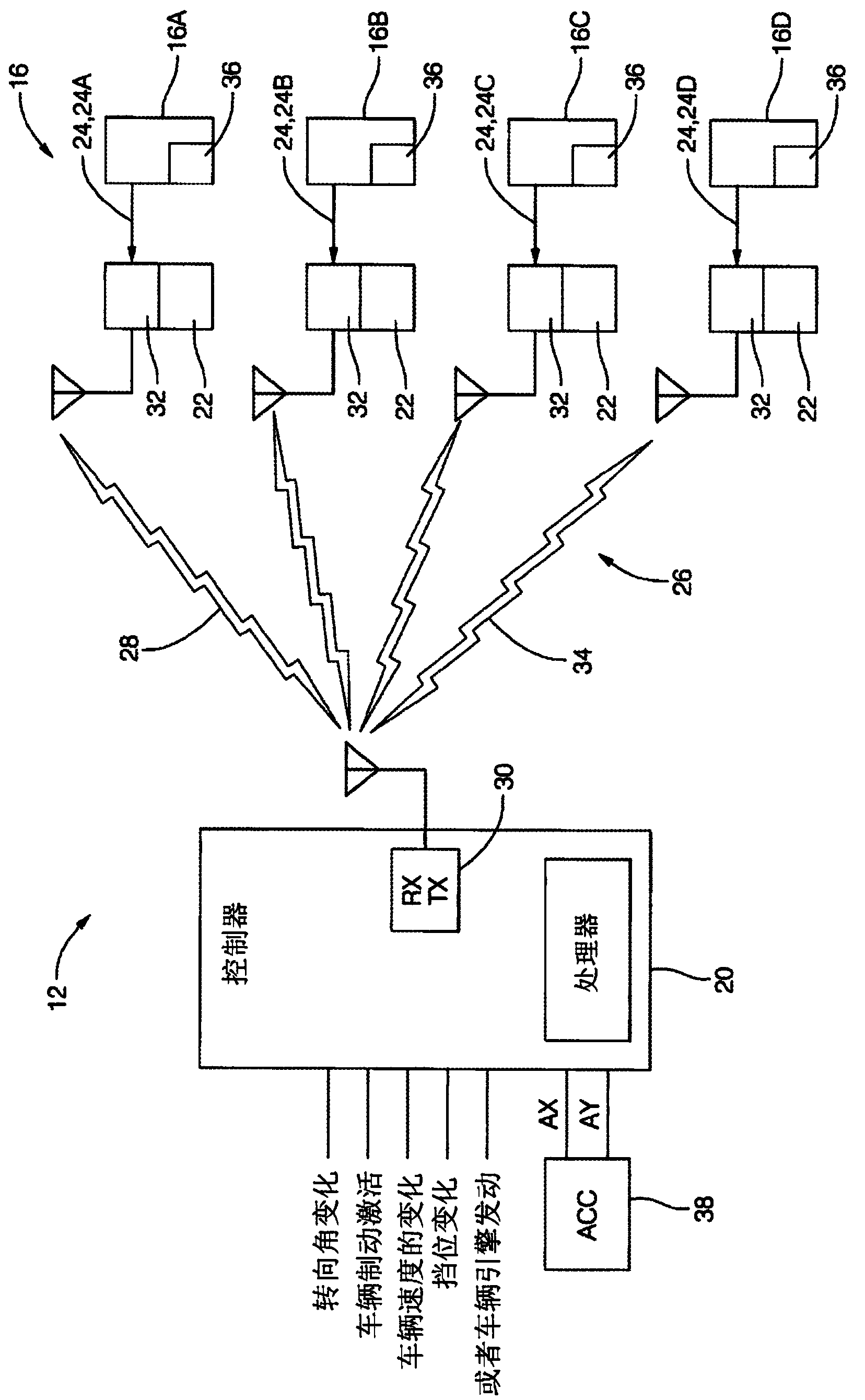

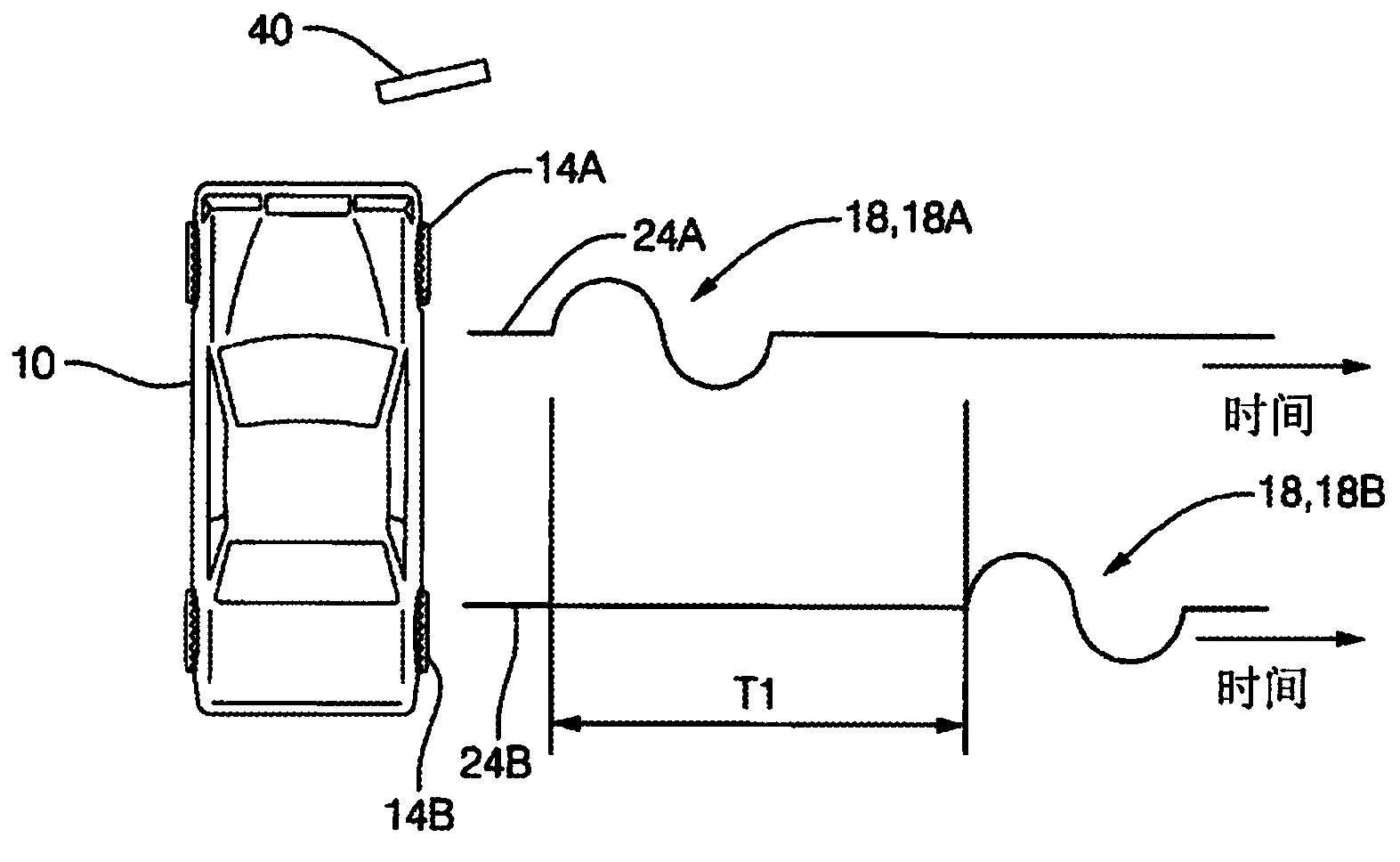

[0016] A tire pressure monitoring system and method is described herein that uses changes or fluctuations in tire pressure to determine the vehicle's wheel position (e.g., front right (RF), rear right (RR), front left (LF), and rear left (LR) ). Generally speaking, a proper change in tire pressure is short-lived in a natural state, usually caused by the vehicle turning or the vehicle driving through some uneven roads. The changes are analyzed and a comparison of these pressure changes from one wheel to another can be used to determine the wheel position. In this way, the wheel positions can be determined by the system without manual programming or other intervention by a service technician or vehicle owner, ie, the system has an automatic wheel position assignment feature. The system and method overcomes the long-standing problem of automating wheel position identification without adding undesired vehicle expense and avoids possible human error by eliminating manual assignmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com