A method for cleaning objects before electroplating

A technology for objects and cleaning tanks, applied in the field of cleaning technology, can solve the problems of high processing costs, reduced economic benefits, and difficult sewage treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

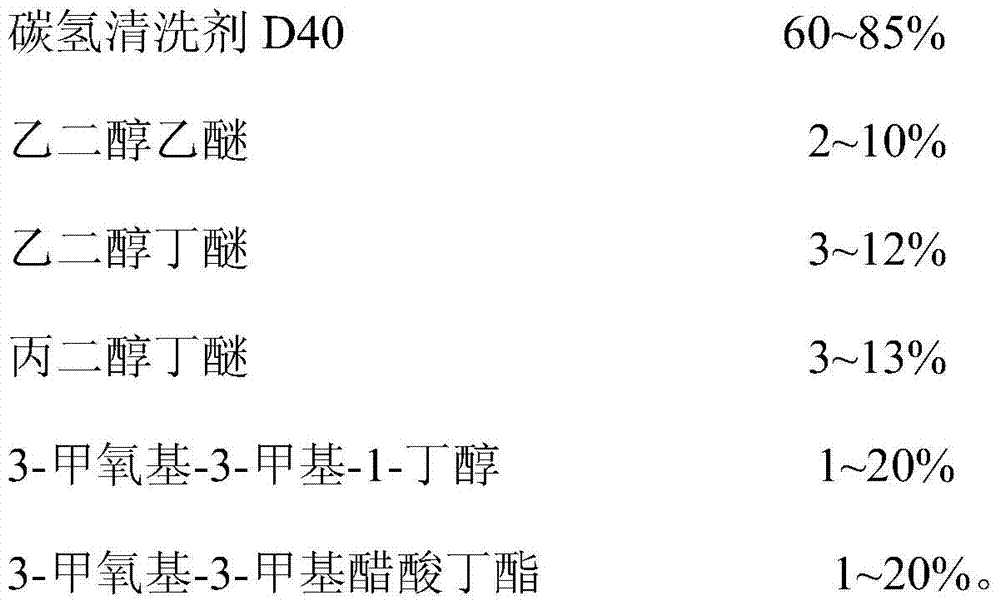

Method used

Image

Examples

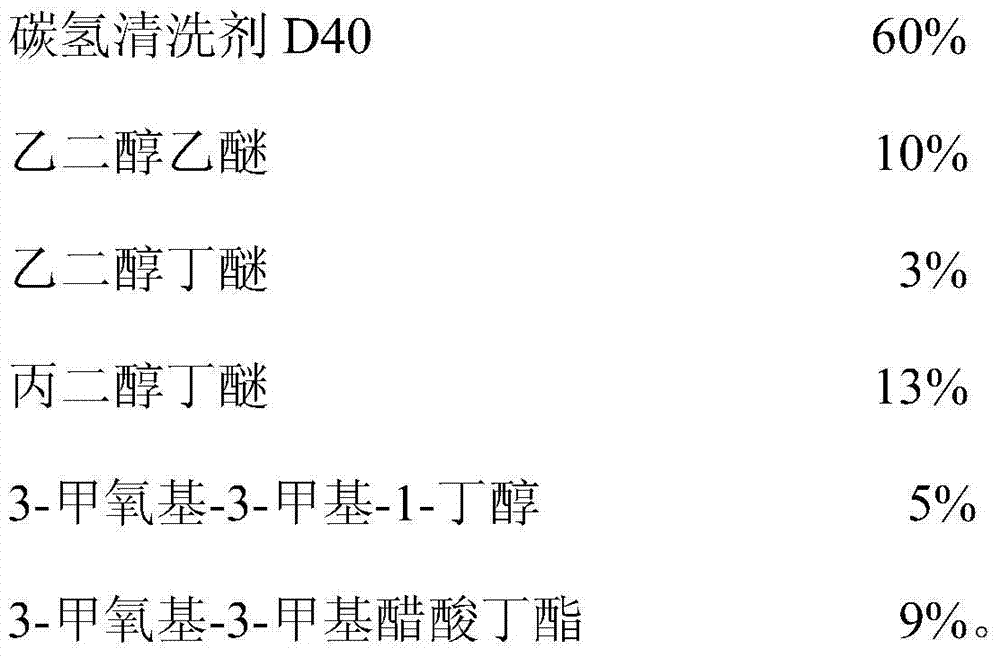

Embodiment 1

[0035] A method for cleaning an object before electroplating of the present invention comprises the following processing steps:

[0036] Degumming: immerse the object in the first cleaning tank containing the degumming agent for ultrasonic cleaning for 3 minutes, and control the temperature of the degumming agent in the first cleaning tank to 80°C;

[0037] Remove water-soluble dirt: transfer the objects in the first cleaning tank and immerse them in the second cleaning tank filled with wax removal water for 3 minutes, and control the temperature of the wax removal water in the second cleaning tank to 90°C;

[0038] Rinsing: Transfer the objects in the second cleaning tank and immerse them in the third cleaning tank filled with tap water for rinsing for 3 minutes, and control the temperature of the tap water in the third cleaning tank to 75°C;

[0039] Remove oil-soluble dirt: transfer and immerse the objects in the third cleaning tank into the fourth cleaning tank containing ...

Embodiment 2

[0056] A method for cleaning an object before electroplating of the present invention comprises the following processing steps:

[0057] Degumming: immerse the object in the first cleaning tank containing the degumming agent for ultrasonic cleaning for 4 minutes, and control the temperature of the degumming agent in the first cleaning tank to 70°C;

[0058] Remove water-soluble dirt: transfer the objects in the first cleaning tank and immerse them in the second cleaning tank filled with wax removal water for 4 minutes of ultrasonic cleaning, and control the temperature of the wax removal water in the second cleaning tank to 80°C;

[0059] Rinsing: Transfer the objects in the second cleaning tank and immerse them in the third cleaning tank filled with tap water for rinsing for 4 minutes, and control the temperature of the tap water in the third cleaning tank to 65°C;

[0060] Remove oil-soluble dirt: transfer and immerse the objects in the third cleaning tank into the fourth cl...

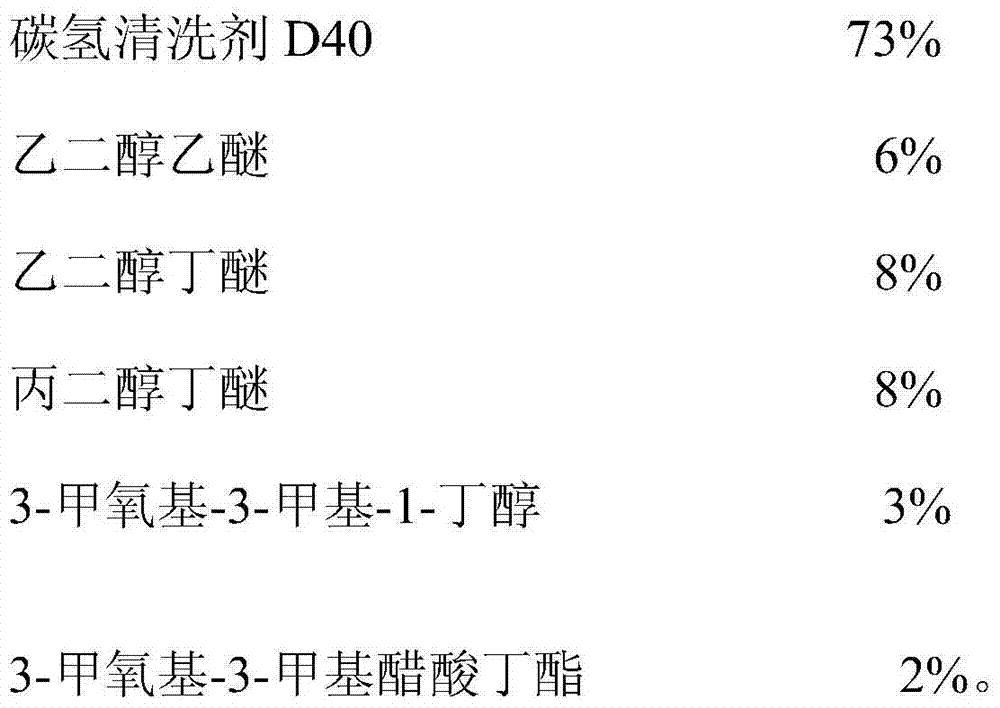

Embodiment 3

[0077] A method for cleaning an object before electroplating of the present invention comprises the following processing steps:

[0078] Degumming: immerse the object in the first cleaning tank equipped with a degumming agent for ultrasonic cleaning for 5 minutes, and control the temperature of the degumming agent in the first cleaning tank to 60°C;

[0079] Remove water-soluble dirt: transfer the objects in the first cleaning tank and immerse them in the second cleaning tank filled with wax removal water for ultrasonic cleaning for 5 minutes, and control the temperature of the wax removal water in the second cleaning tank to 70°C;

[0080] Rinsing: Transfer the objects in the second cleaning tank and immerse them in the third cleaning tank filled with tap water for rinsing for 5 minutes, and control the temperature of the tap water in the third cleaning tank to 55°C;

[0081] Remove oil-soluble dirt: transfer and immerse the objects in the third cleaning tank into the fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com