Lapper

A technology of the lasting machine and the driving mechanism, which is applied in the field of sewing machines, can solve the problems of inconvenient use and complicated design of the transmission mechanism, and achieve the effect of convenient operation and simplified mechanical transmission parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to further have a clear and detailed understanding and understanding of the structure, use and characteristics of the present invention, the preferred embodiments are now cited, and detailed descriptions are as follows in conjunction with the accompanying drawings:

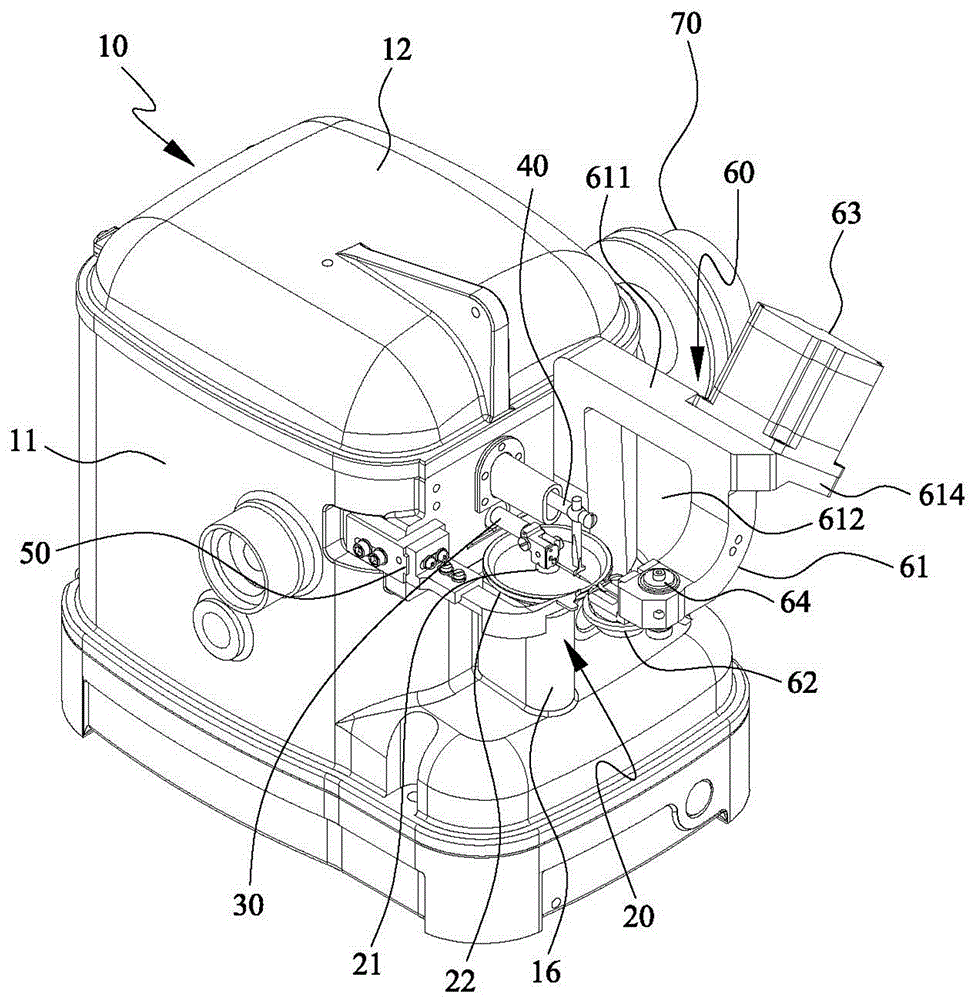

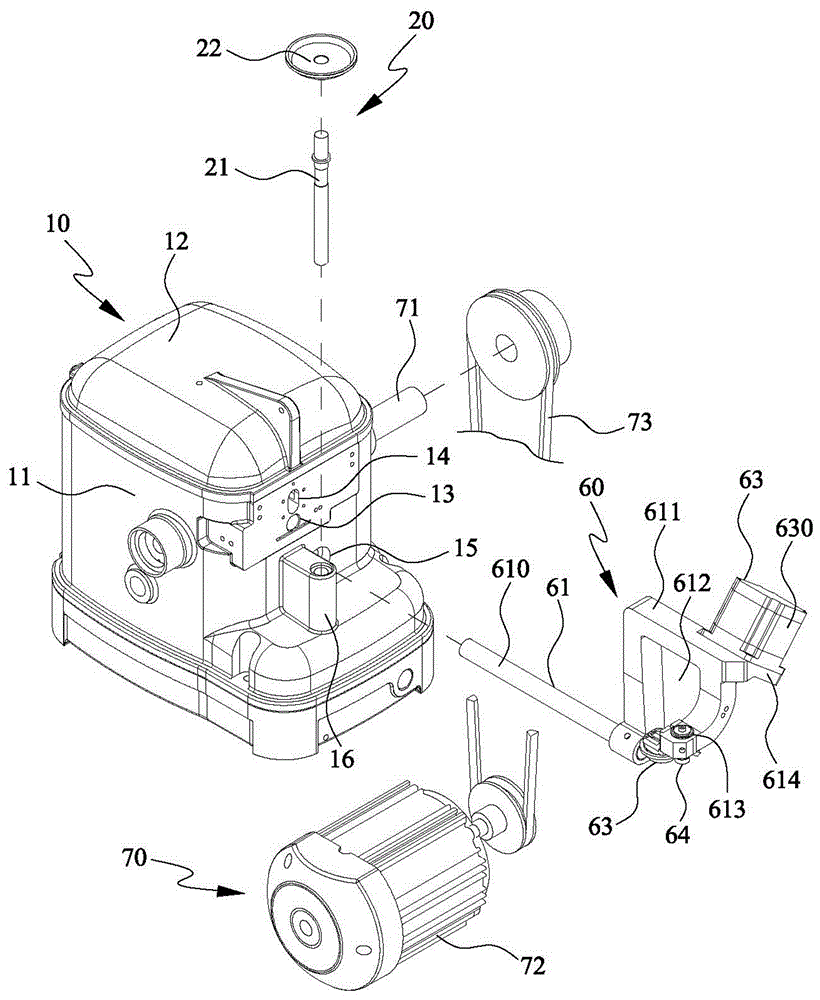

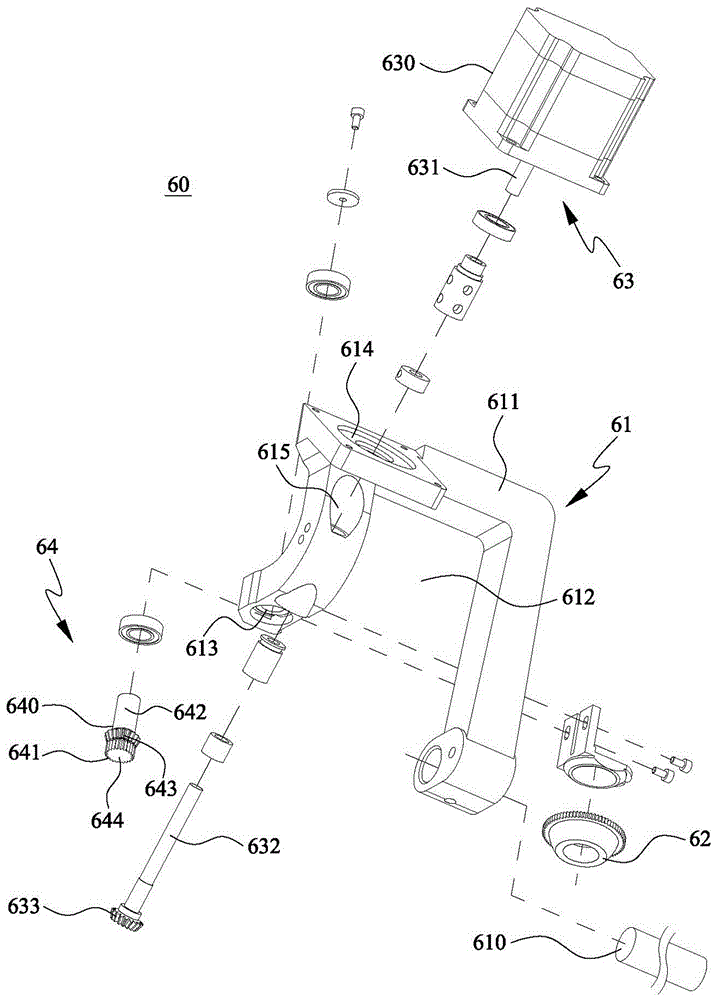

[0079] see figure 1 and figure 2 As shown, the lasting machine of the present invention is mainly a sewing machine for sewing the edges on both sides of the sole. The blocking mechanism 50, a lubricating mechanism (not shown), a feeding moving mechanism 60 and a first driving mechanism 70 are jointly formed.

[0080] Since the key part of the present invention is that the above-mentioned feeding moving mechanism 60 adopts an independent driving source, and other parts are all the same as the traditional lasting machine, for the convenience of showing the characteristics of the present invention, the figure 2 The components are simplified without showing the internal structures of the above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com