End cap of lamp tube and lighting device using the end cap

A technology for lighting devices and end caps, which is applied in the direction of lighting devices, lighting auxiliary devices, components of lighting devices, etc., and can solve the problems of increasing the volume of lighting devices, high production costs, and unfavorable safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

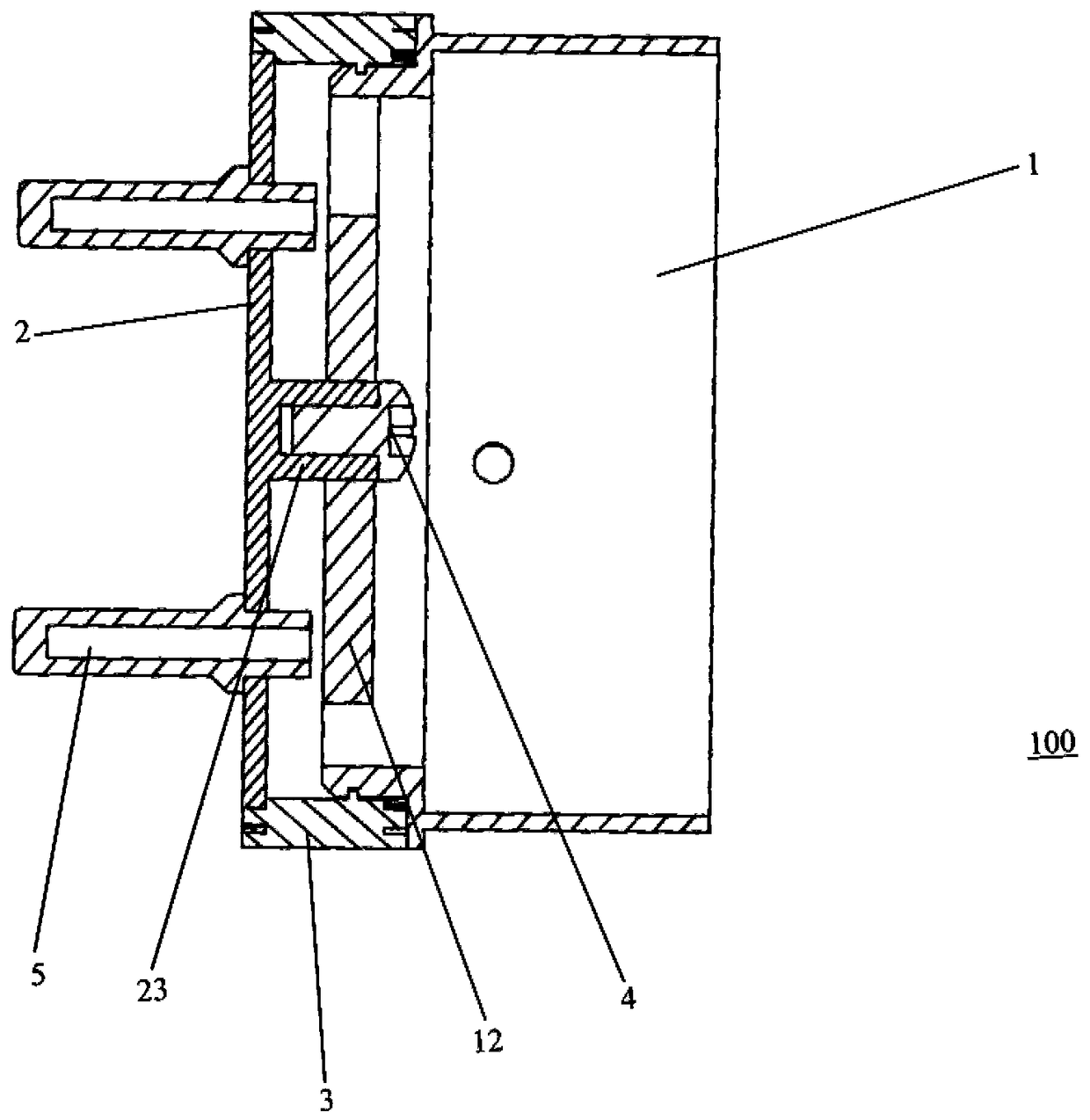

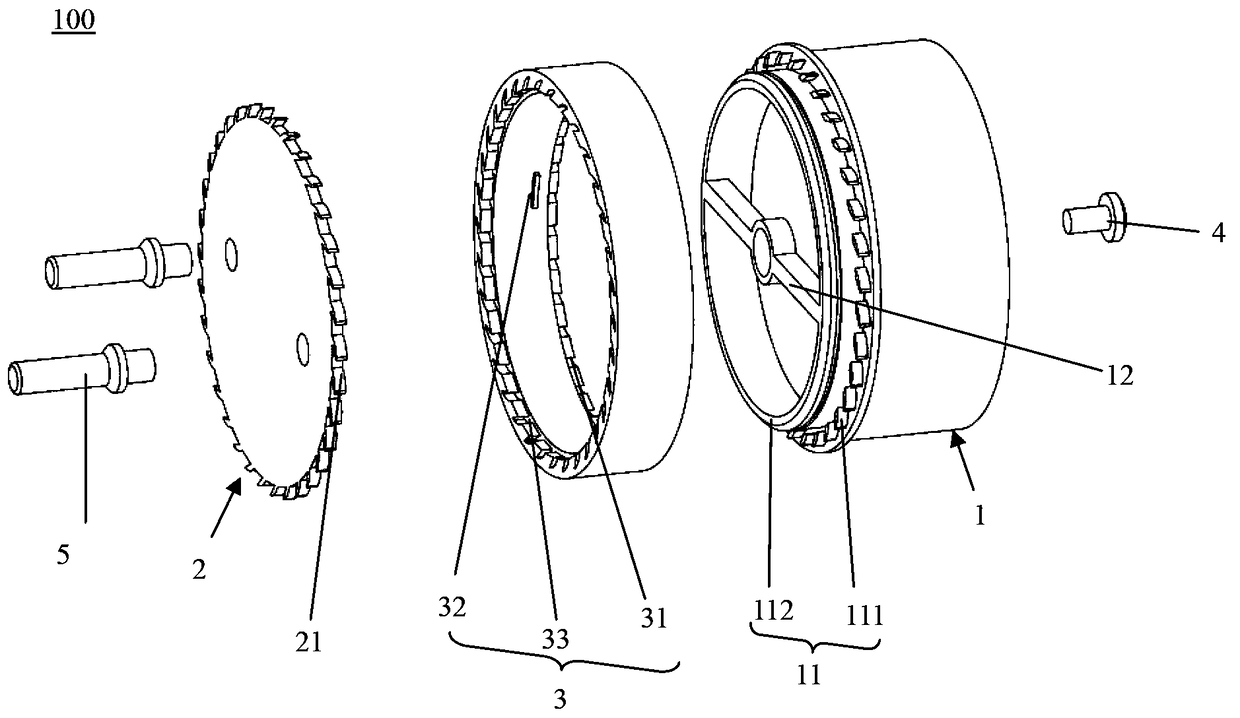

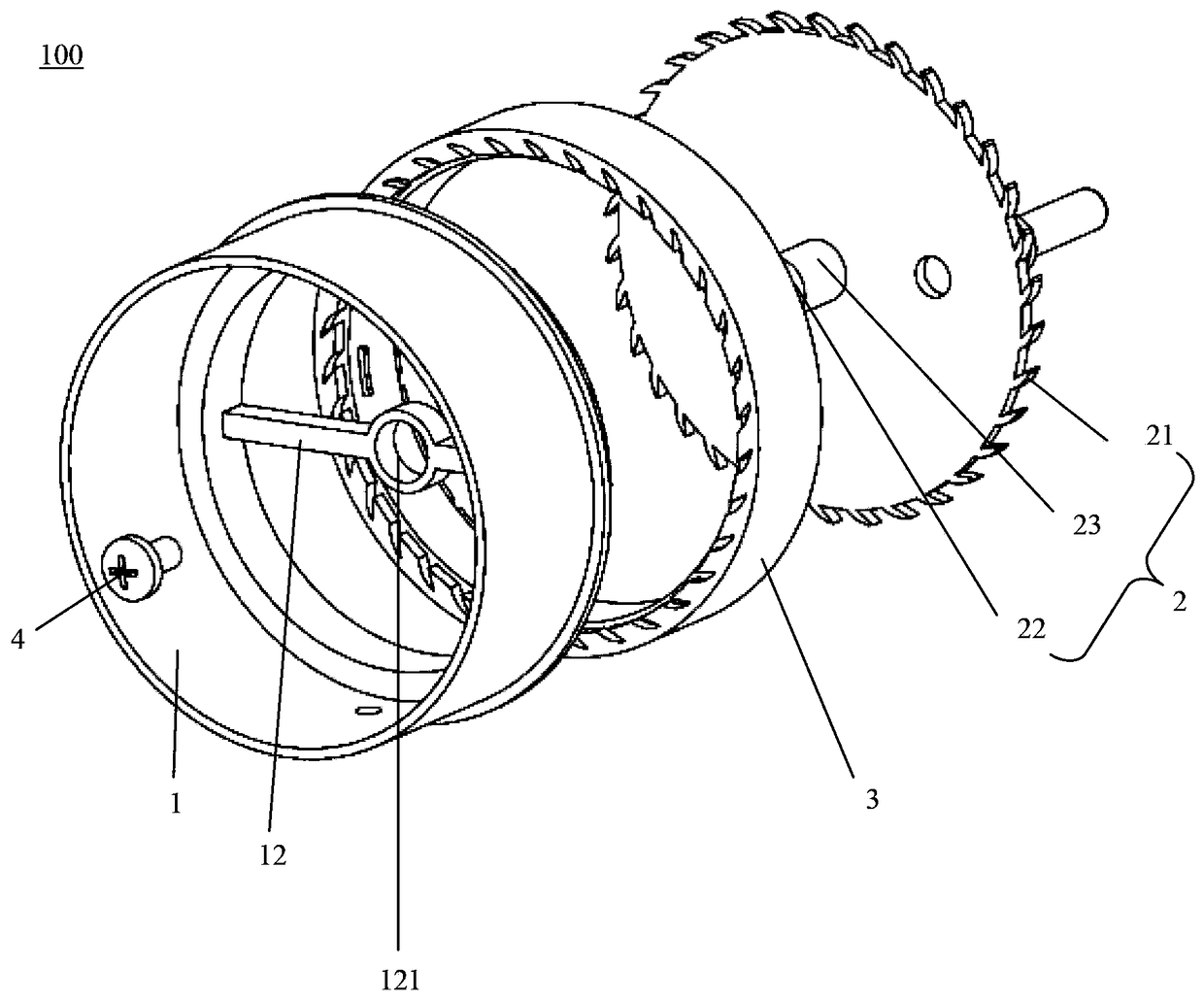

[0028] According to an embodiment of the present invention, the designed end cap 100 has main parts such as an assembly ring 1, a rotating ring 3 and a cover plate 2, such as figure 1 as shown, figure 1 is a cross-sectional view of an end cap 100 according to the present invention. It can be seen from the figure that the end cover 100 includes an assembly ring 1 , a rotating ring 3 and a cover plate 2 sequentially in the axial direction, and the purpose of assembling the end cover 100 can be realized by connecting the above three main parts to each other. Wherein, a support beam 12 is provided in the end cover 100, and a through hole is also provided on the support beam 12. In addition, a cylindrical rotating shaft 23 is also designed on the cover plate 2, so that the bolt 4 passes through the through hole and The rotating shaft 23 is connected to realize the purpose of connecting the assembly ring 1 , the rotating ring 3 and the cover plate 2 . The structure of the end cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com