Water heater

A technology for water heaters and water pipelines, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low water preheating efficiency, users need to wait, and water users need to wait, etc., to achieve rapid heating, The effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

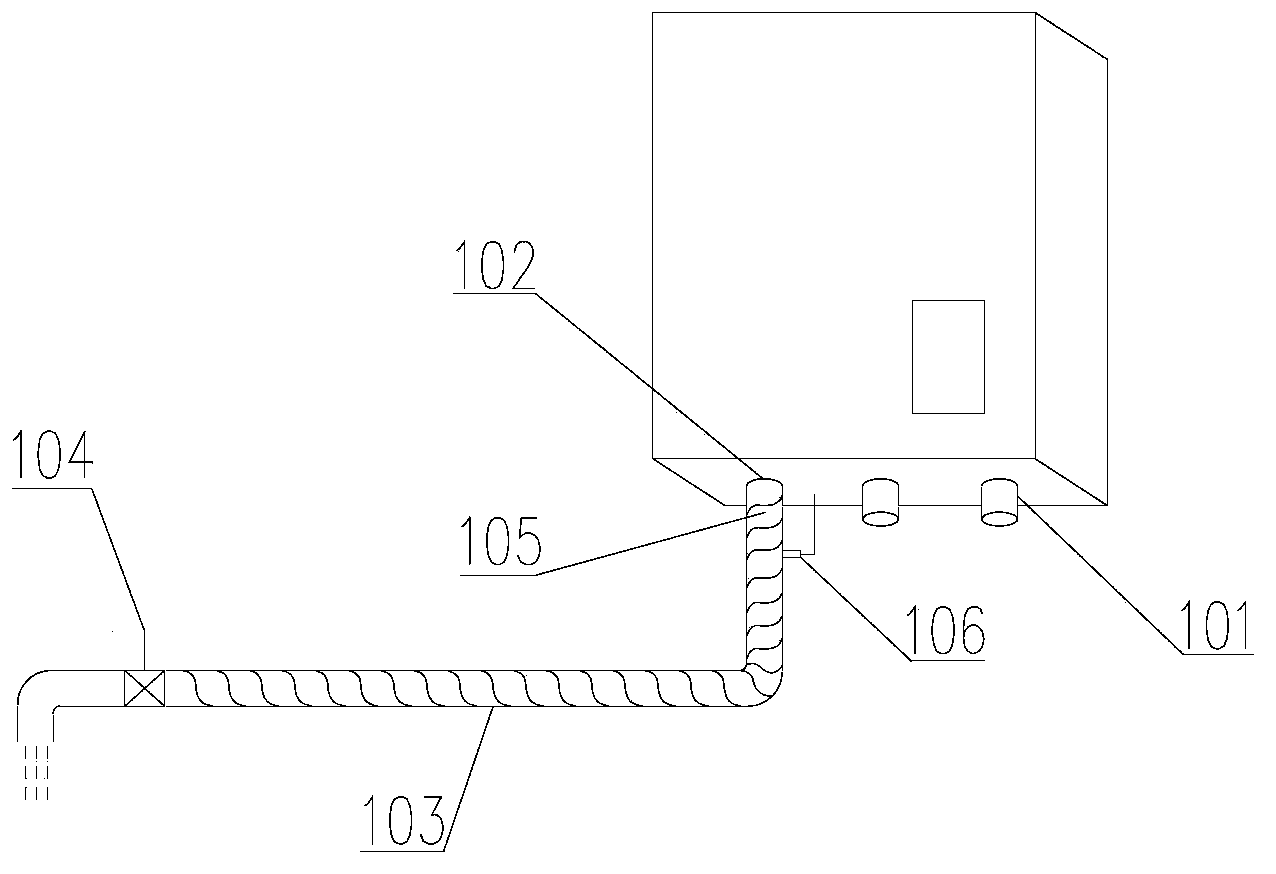

[0028] Such as figure 1 As shown, the water heater in this embodiment is a gas water heater, which includes a water inlet 101, a water outlet 102, and a water pipeline 103 connected to the water outlet 102, and a water valve 104 is provided at the water outlet end of the water pipeline 103; Because the existing water heater needs to discharge the cold water in the water pipeline 103 before use, it will cause waste of water resources and require users to wait. To solve this problem, in this embodiment, a heating device 105 is provided on the water pipeline 103, and the heating device 105 is an electric heating wire or an electric heating belt, which is used to heat the water in the water pipeline, so that the user can Hot water can be obtained when the water heater is turned on, which avoids the waste of cold water before and reduces the waiting time of users.

[0029] The above-mentioned electric heating belt is a strip structure with electric heating wires inside, and the el...

Embodiment approach 2

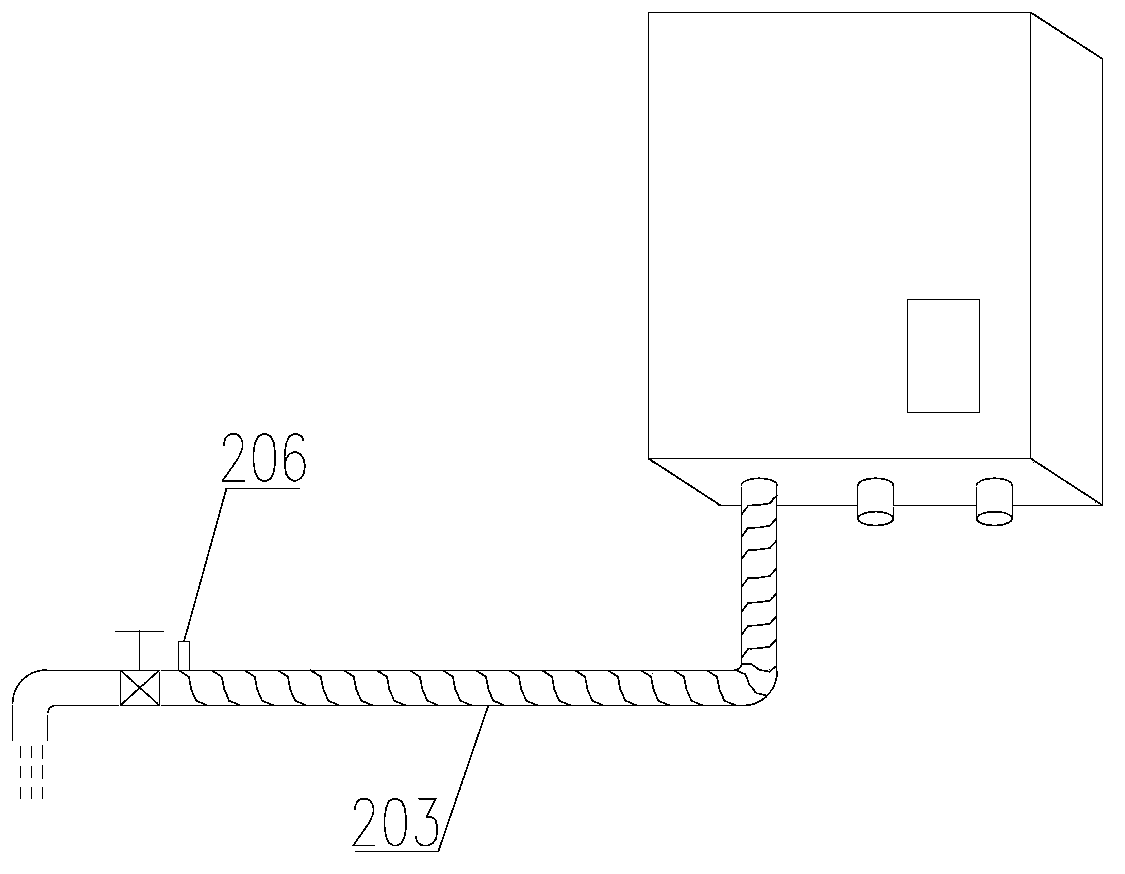

[0037] Such as figure 2 As shown, in this embodiment, the temperature sensor 206 is arranged near the water outlet end of the water pipeline 203. Since the temperature sensor 206 is arranged near the water outlet end of the water pipeline 203, the detected water temperature information is closer to The water temperature to be used by the user further improves the accuracy of controlling the water temperature in the water pipeline 203 . In this embodiment, except that the location of the temperature sensor is different from that of the first embodiment, other structures are the same as those of the first embodiment.

Embodiment approach 3

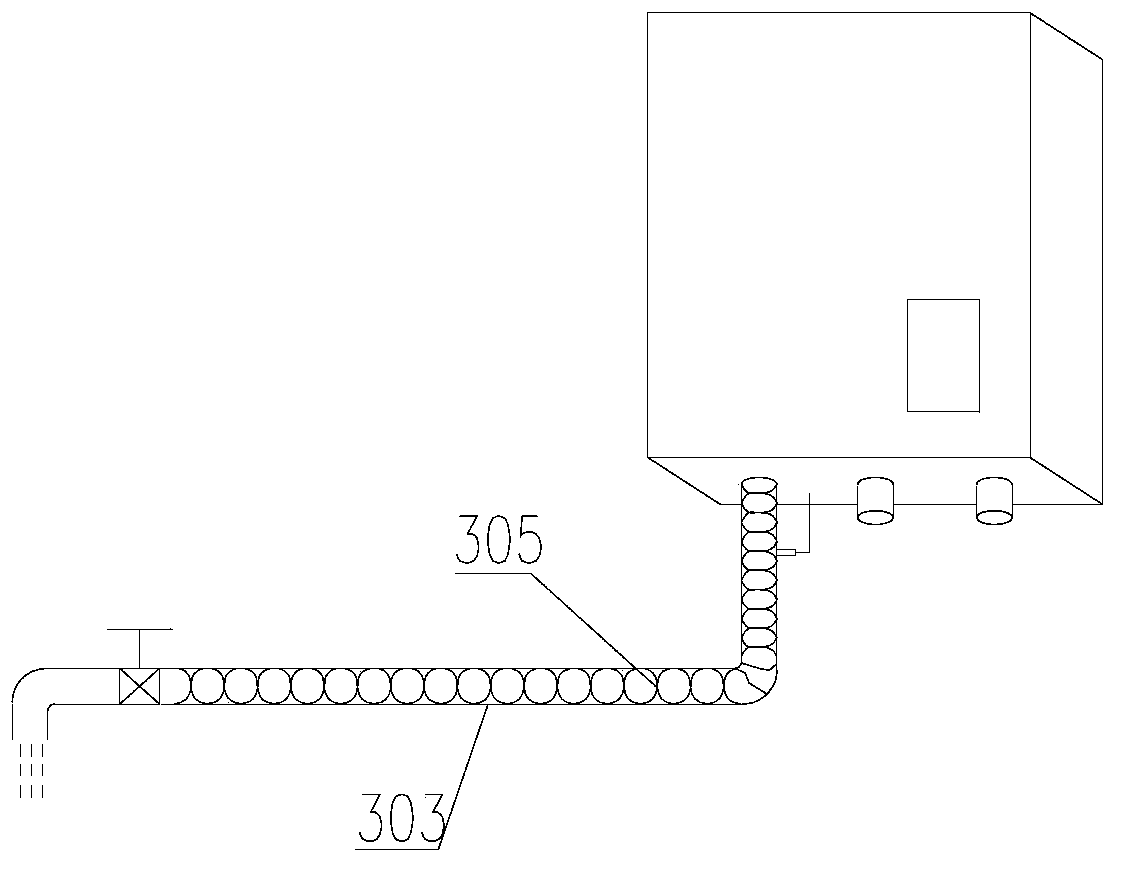

[0039] Such as image 3 As shown, in this embodiment, the heating device 305 is a grid-like structure formed by electric heating wires intersecting in a left-hand helix and a right-hand helix. The heating device 305 of this structure can heat the water in the water pipeline 303 higher efficiency. In this embodiment, except that the structure of the heating device is different from that of the first or second embodiment, other structures are the same as those of the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com