A spring force value sensor for tensile testing machine

A tensile testing machine and spring force technology, which is applied in the measurement of elastic deformation force by measuring gauges, etc., can solve the problems of narrow sensor range and unsuitable for anchor chain tensile testing machine, etc. High linearity and high repeatability, the effect of improving the anti-overload capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

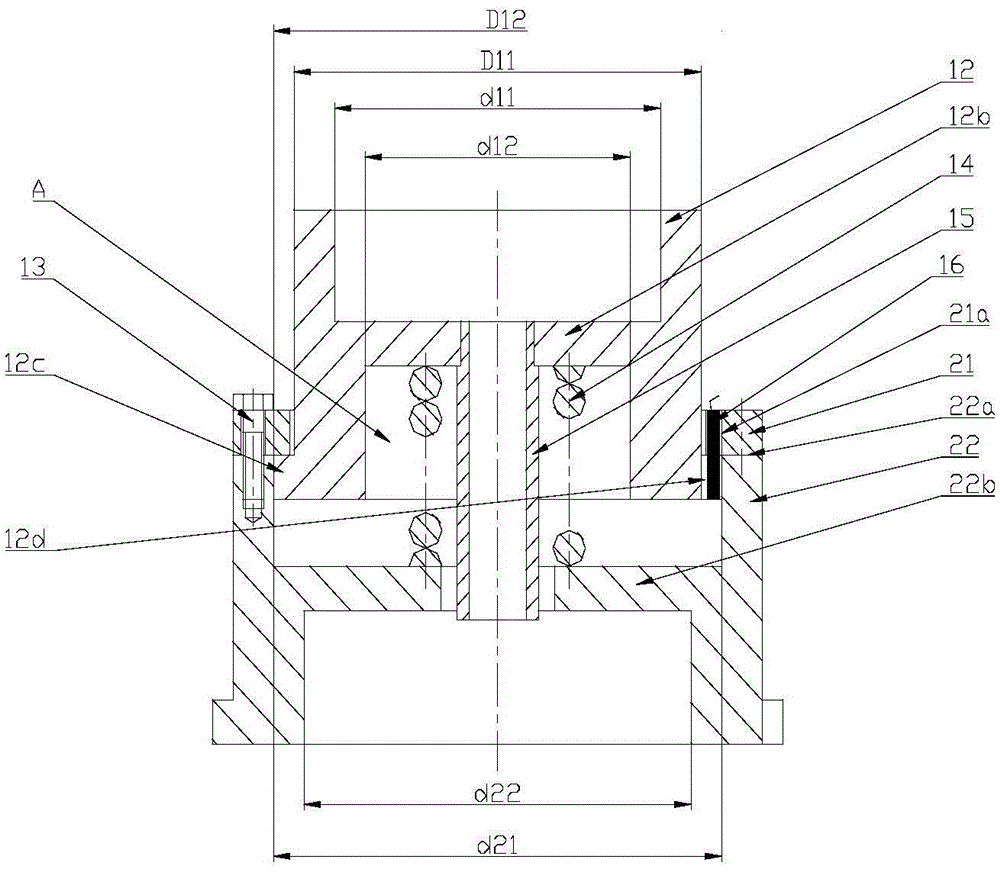

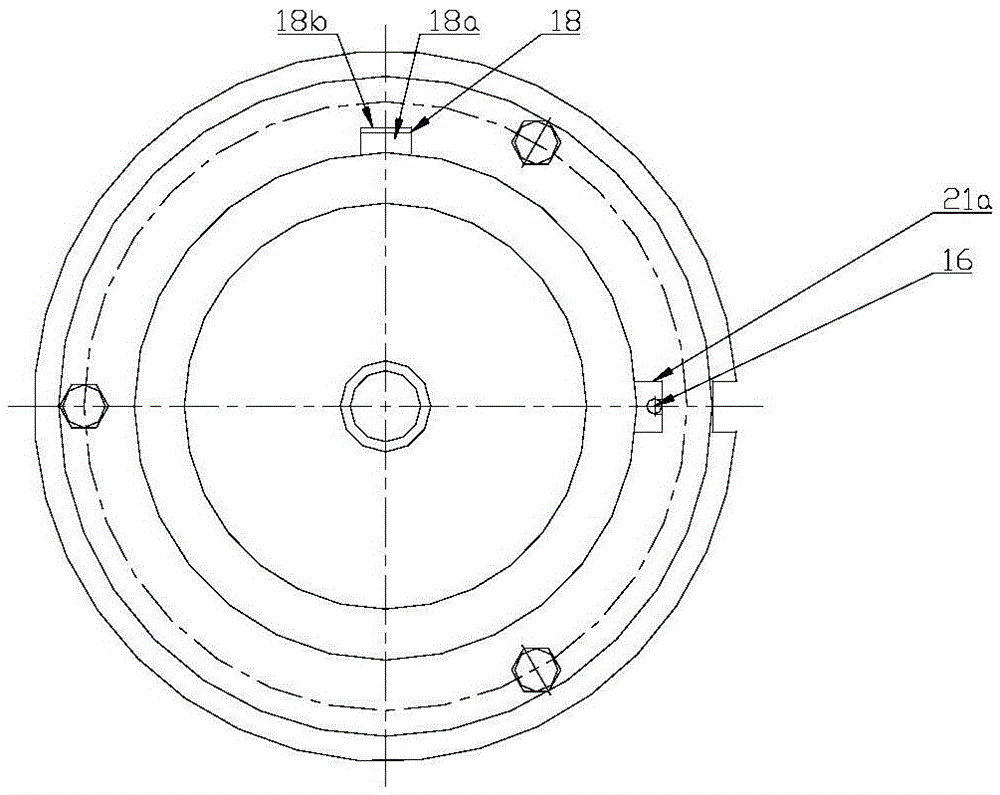

[0014] Below in conjunction with accompanying drawing, the present invention will be further described:

[0015] Such as figure 1 with figure 2 Shown is a spring force value sensor of a tensile testing machine of the present invention, comprising an upper pressure cylinder 12, a lower pressure cylinder 22, a disc spring 14, a limit flange 21, a displacement sensor 16 and a guide 18, the The upper pressure cylinder 12 and the lower pressure cylinder 22 have the same structure as a circular cylinder, and a partition 12b is provided in the middle of the cylinder 12 to divide the cavity of the cylinder 12 into upper and lower cavities. There is an annular flange 12c with a notch 12d, and the annular flange 12c is embedded in the upper cavity of the lower pressure cylinder 22 to form a closed pressure chamber A; the disc spring 14 is placed in the pressure chamber A The limit flange 21 is also provided with a notch 21a, which corresponds to the notch 12d on the flange 12c, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Preload force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com