A multi-layer force value sensor and its measurement method for tensile testing machine

A tensile testing machine and sensor technology, applied in the direction of force/torque/work measuring instrument calibration/test, measuring device, measurement of elastic deformation force through measuring gauge, etc., can solve overload under-protection and narrow force sensor range and other problems, to achieve the effect of reducing the overall size, improving the anti-overload capability, and strengthening the anti-overload capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

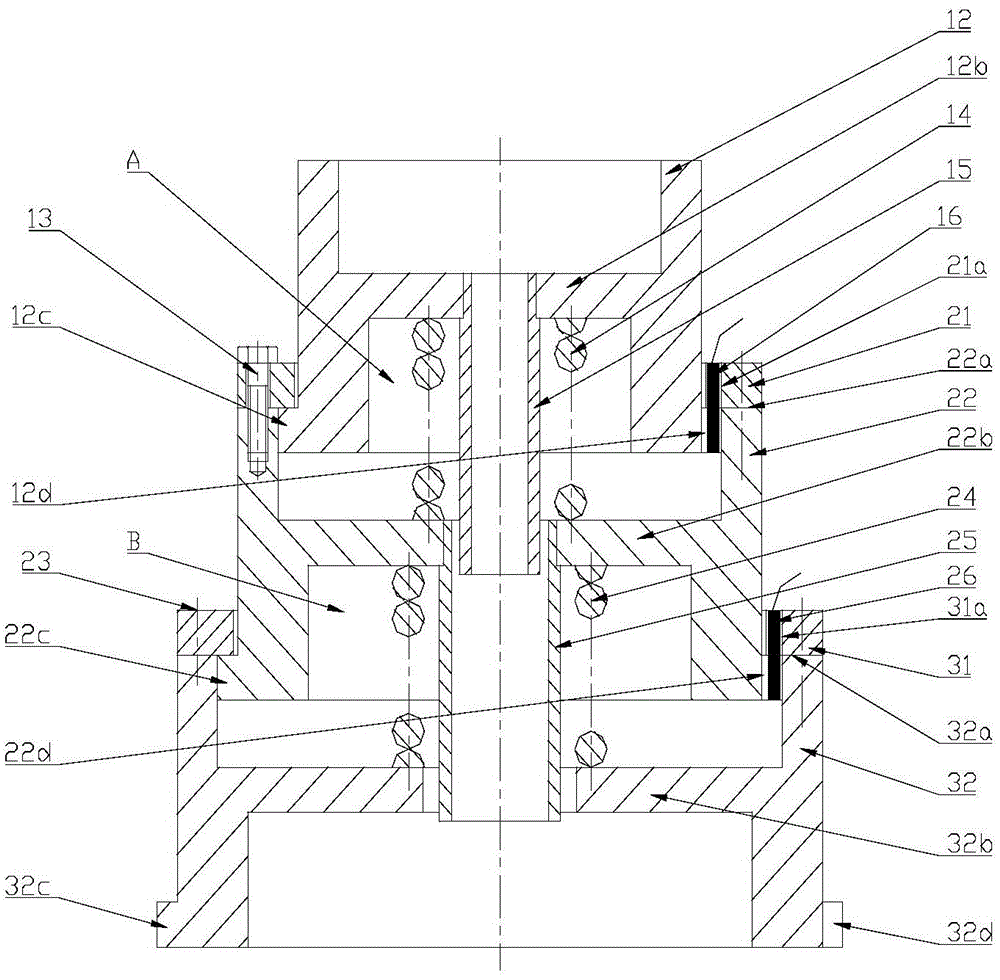

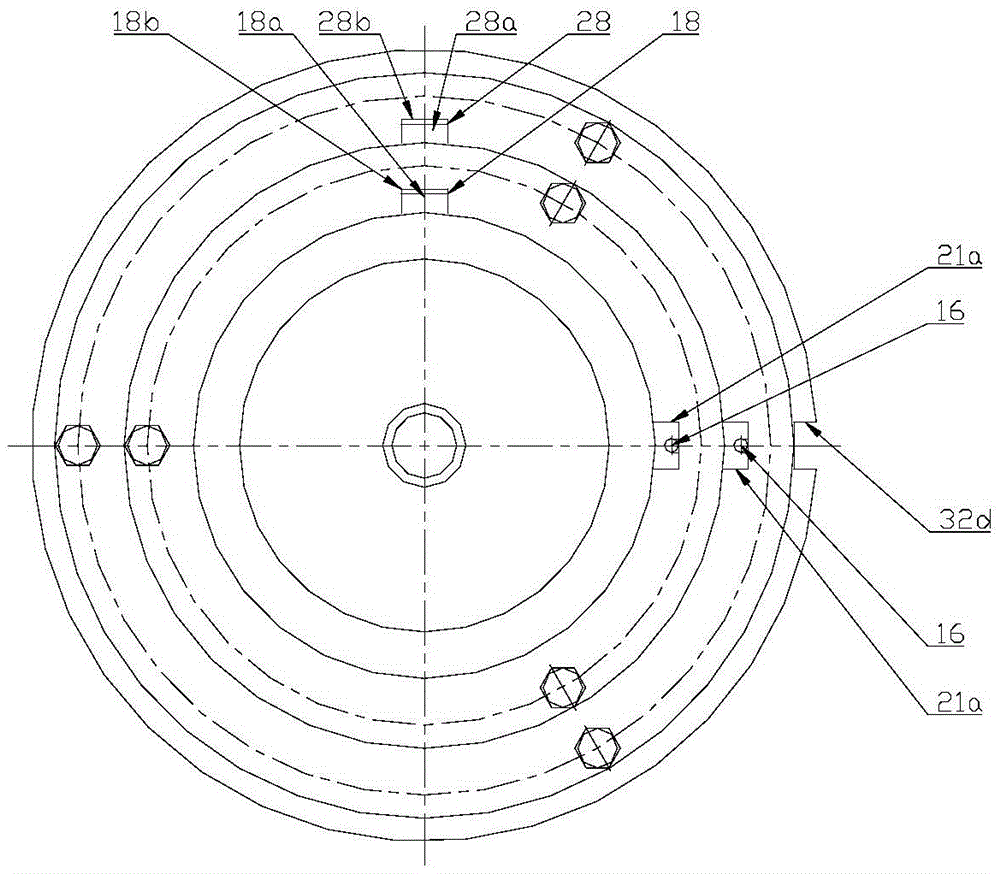

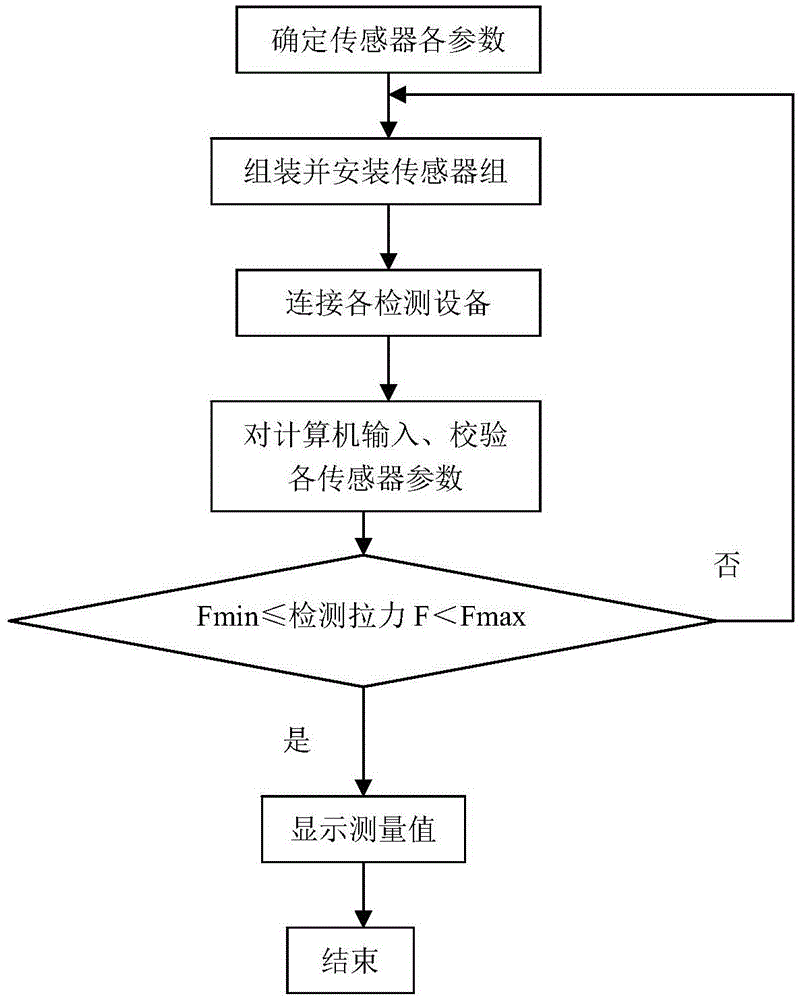

[0030] Such as Figure 1 to Figure 2 As shown, a force sensor for a tensile testing machine is composed of a pressure cylinder, an induction spring, a limit flange, a displacement sensor and a guide device. The pressure cylinder has three layers from top to bottom, that is, the pressure cylinder 12 . The annular flanges 12c, 22c, 32c of the ring flanges 12c, 22c are respectively embedded in the upper cavity of the pressure cylinder 22, 32, forming two closed pressure chambers A, B; Belleville springs 14, 24; the limit flanges 21, 31 are also provided with gaps 21a, 31a, corresponding to the gaps 12d, 22d on the ring flange, and fixed on the upper plane 22a, 22a of the pressure cylinder by screws 13, 23 32a; the two ends of the displacement sensors 16, 26 are respectively fixed in the gaps of 12d-21a and 22d-31a; the guides 18, 28 are the fixed keys 18a, 28a and The key ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com