A special detection device for feeding bottles

A detection device and milk bottle technology, which is applied in the directions of measuring devices, instruments, scientific instruments, etc., can solve the inconvenience of self-inspection and inspection units of milk bottle manufacturers, easy damage to the bottle body, poor adaptability and versatility of the clamping device, etc. problem, to achieve the effect of convenient performance testing, convenient pulling resistance performance and puncturing performance testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

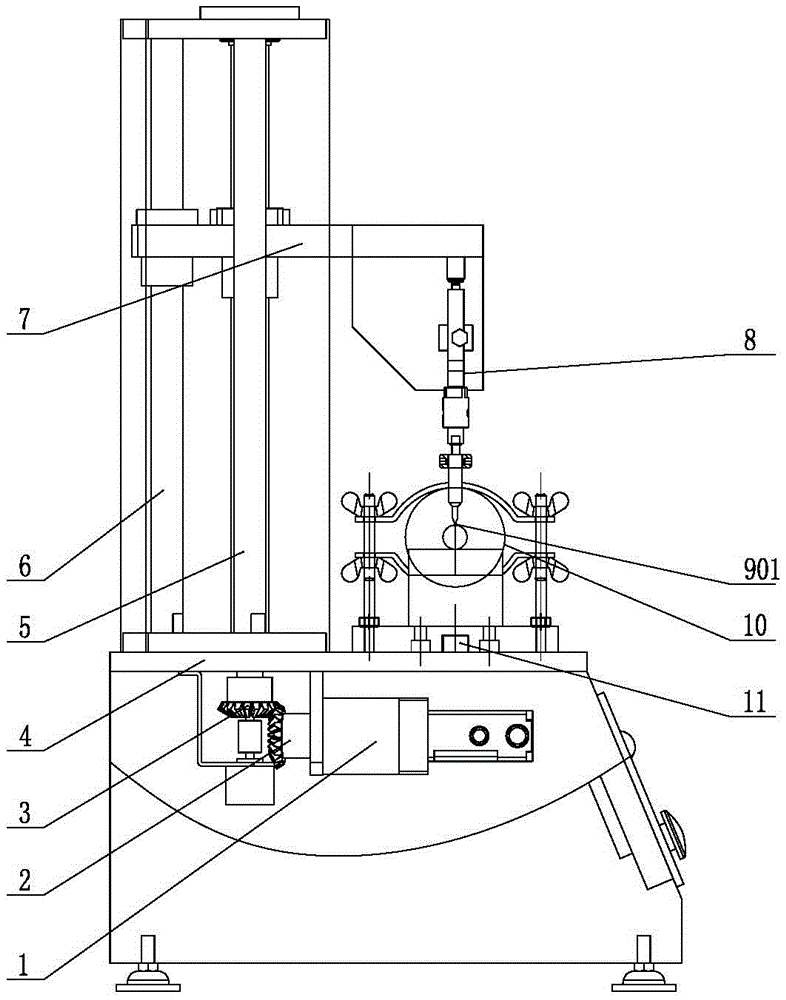

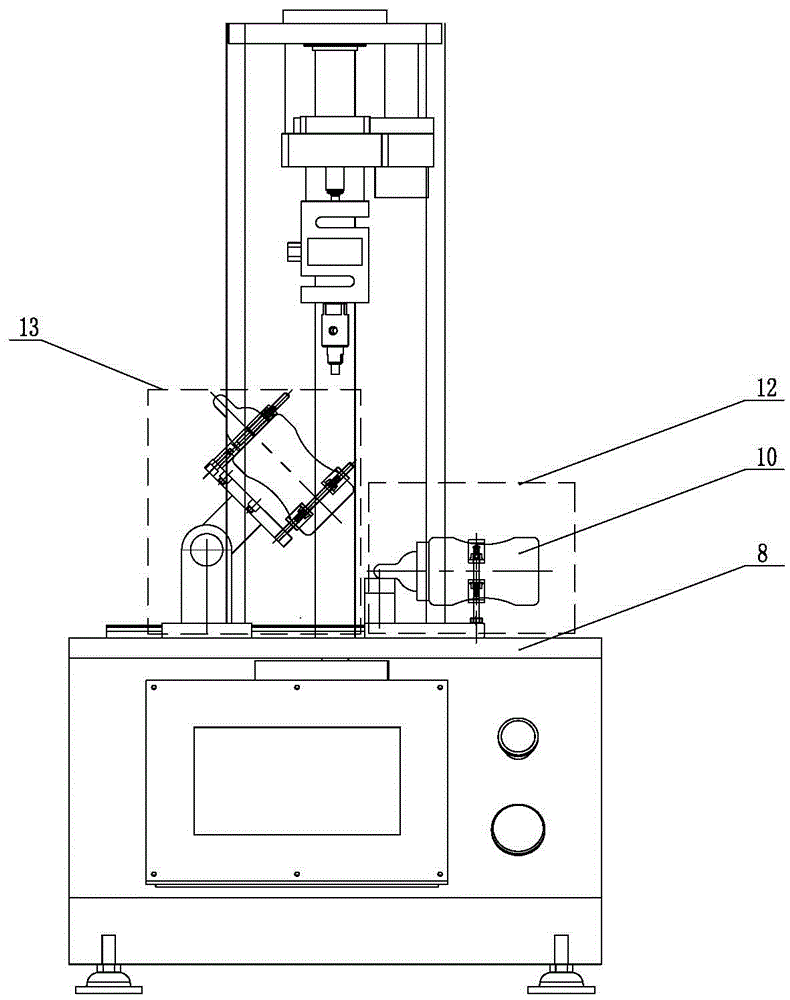

[0021] Such as figure 1 , figure 2 and Figure 4 — Figure 7 Shown is the special detection device for feeding bottles according to Embodiment 1 of the present invention, including a workbench 4, and the lower side of the workbench 4 is provided with a bevel gear 1 2 and a bevel gear 2 3 meshing with each other, and the bevel gear 1 2 is horizontally arranged and the input end is connected to the The motor 1 is connected, the bevel gear 2 3 is vertically arranged, and the end of the gear shaft of the bevel gear 2 3 is fixed with an upwardly extending screw shaft 5; the upper side of the workbench 4 is provided with a vertical guide rail 6, and the vertical guide rail 6 is slidingly connected to horizontally set up and down Arm 7, the lifting arm 7 is provided with an internally threaded hole matched with the thread of the screw shaft 5, the lower side of the lifting arm 7 is connected with a side force transmission sense 8 and a test head connected to the load cell 8, the t...

Embodiment 2

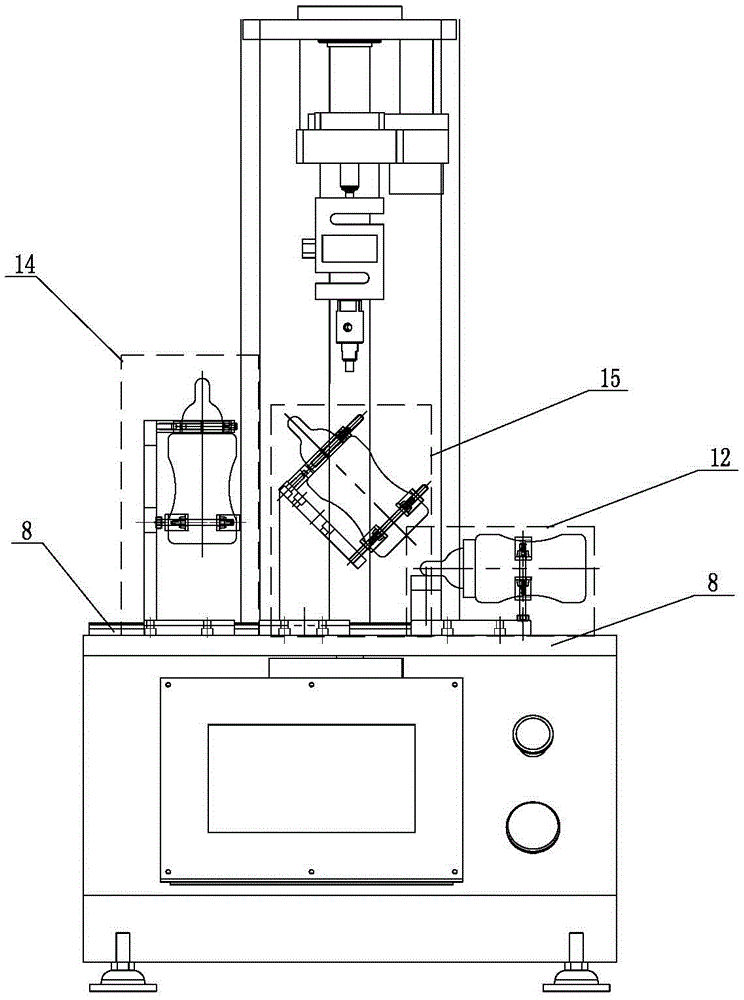

[0026] Such as figure 2 , Figure 4 , Figure 5 , Figure 8 with Figure 9 Shown, be the feeding bottle special detection device of the invention embodiment 2 of the present invention, differ from embodiment 1 in that, as Figure 8 with Figure 9 As shown, in the present embodiment, the anti-pull test fixtures are respectively set as the anti-pull test fixture one 14 for clamping the feeding bottle in the vertical direction and the two 15 for the anti-pull test fixture for clamping the feeding bottle in the direction of 45 °, the anti-pull test Fixture one 14 comprises slide seat three 1401 that cooperates with horizontal guide rail 11, and the position of slide seat three 1401 on the horizontal guide rail can also be locked by bolts, and slide seat three 1401 is provided with vertical support plate one 1402, and support plate one The side of 1402 is respectively provided with paired square splint 2 1404 and paired arc splint 3 1403 for fixing the feeding bottle; The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com