Coating device, coating system and coating method for coating frame sealant

A technology of coating device and coating method, which is applied in the field of coating system and coating, coating device, and frame sealing glue coating device, which can solve the problems that the glue cannot be sprayed down, cannot be reached, and internal charge accumulation, etc., to achieve Avoid the problem of hanging glue, control the amount of suction, and improve the effect of balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

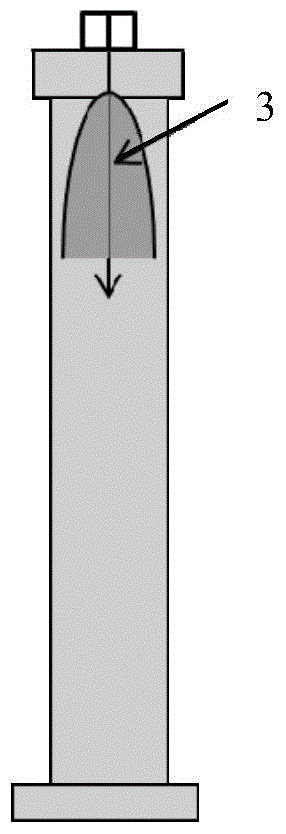

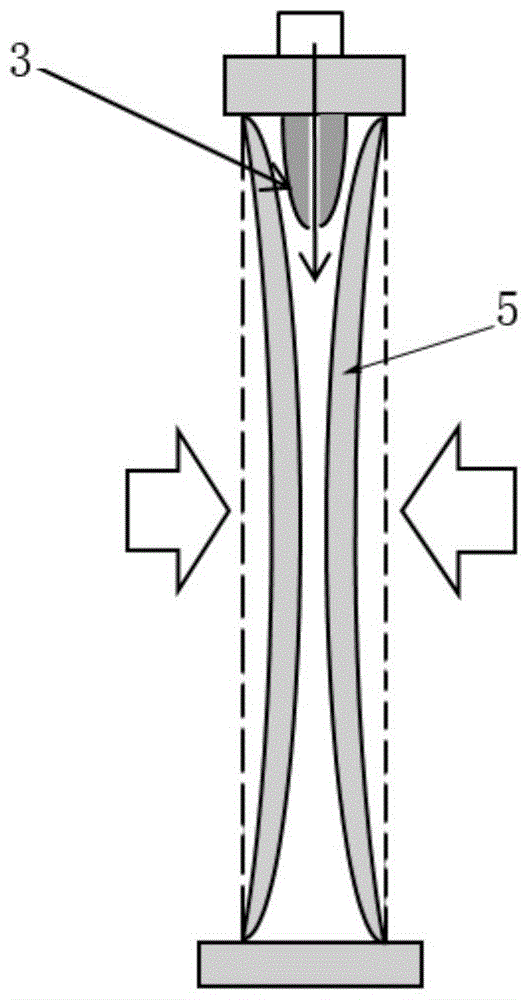

[0049] Such as image 3 As shown, the present invention provides a coating device for coating frame sealant, the rubber storage pipe has two ends, and one end is connected to a gas ejection device ( image 3 The parts connected to the upper end are not shown in the figure), and the other end is connected to the nozzle ( image 3lower end connected parts, not shown in the figure); the tube wall 5 of the rubber storage tube is made of flexible material, and the tube wall 5 can carry out recoverable deformation perpendicular to the axis of the rubber storage tube inward. The coating device will be described in detail below.

[0050] Such as image 3 As shown, when using t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com