Integrated soil-tilling apparatus for rotary ploughs

A technology of turning plows, land, applied in the direction of plows, applications, shovels, etc., which can solve the problem of weakening the longitudinal frame structure costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

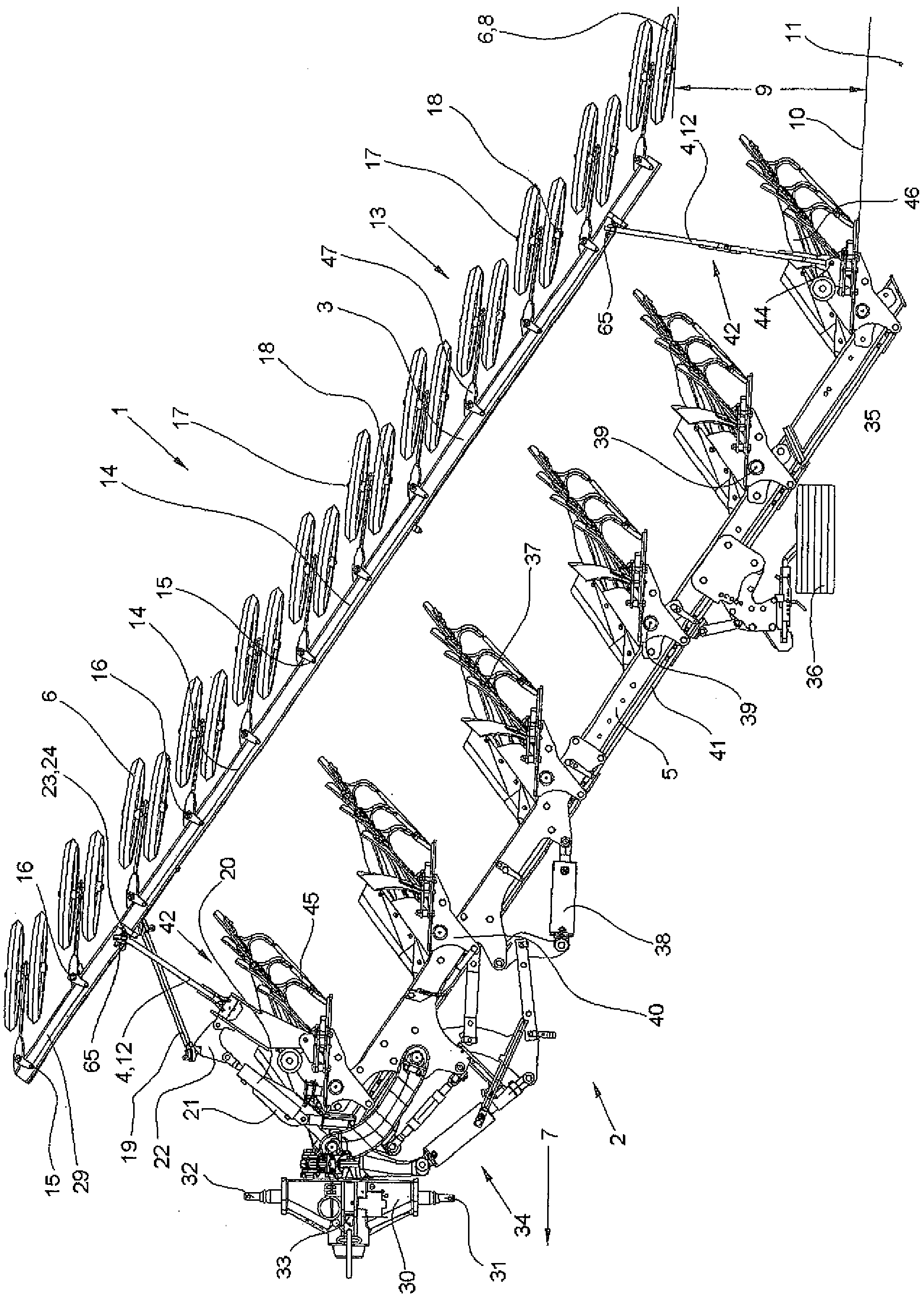

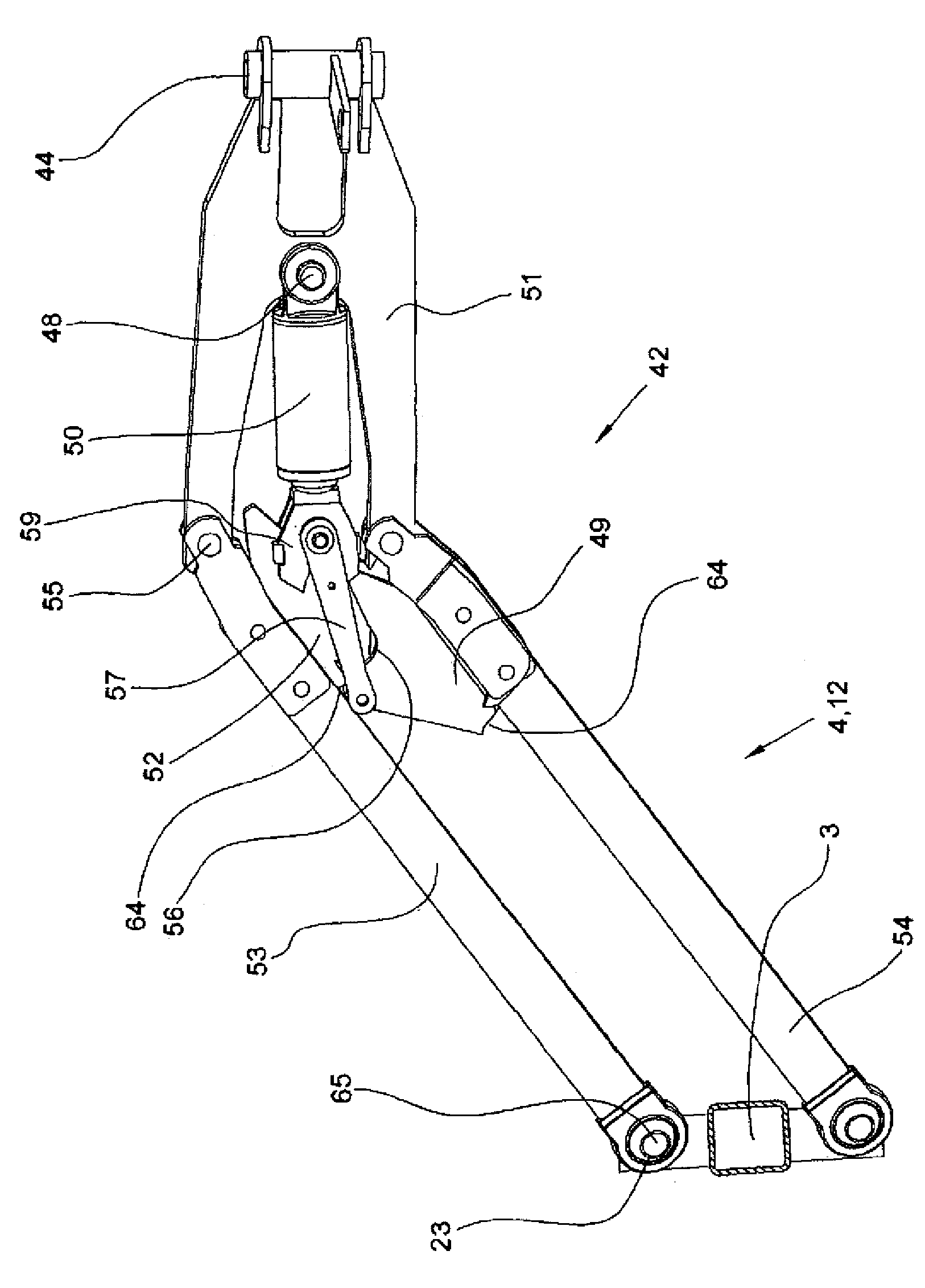

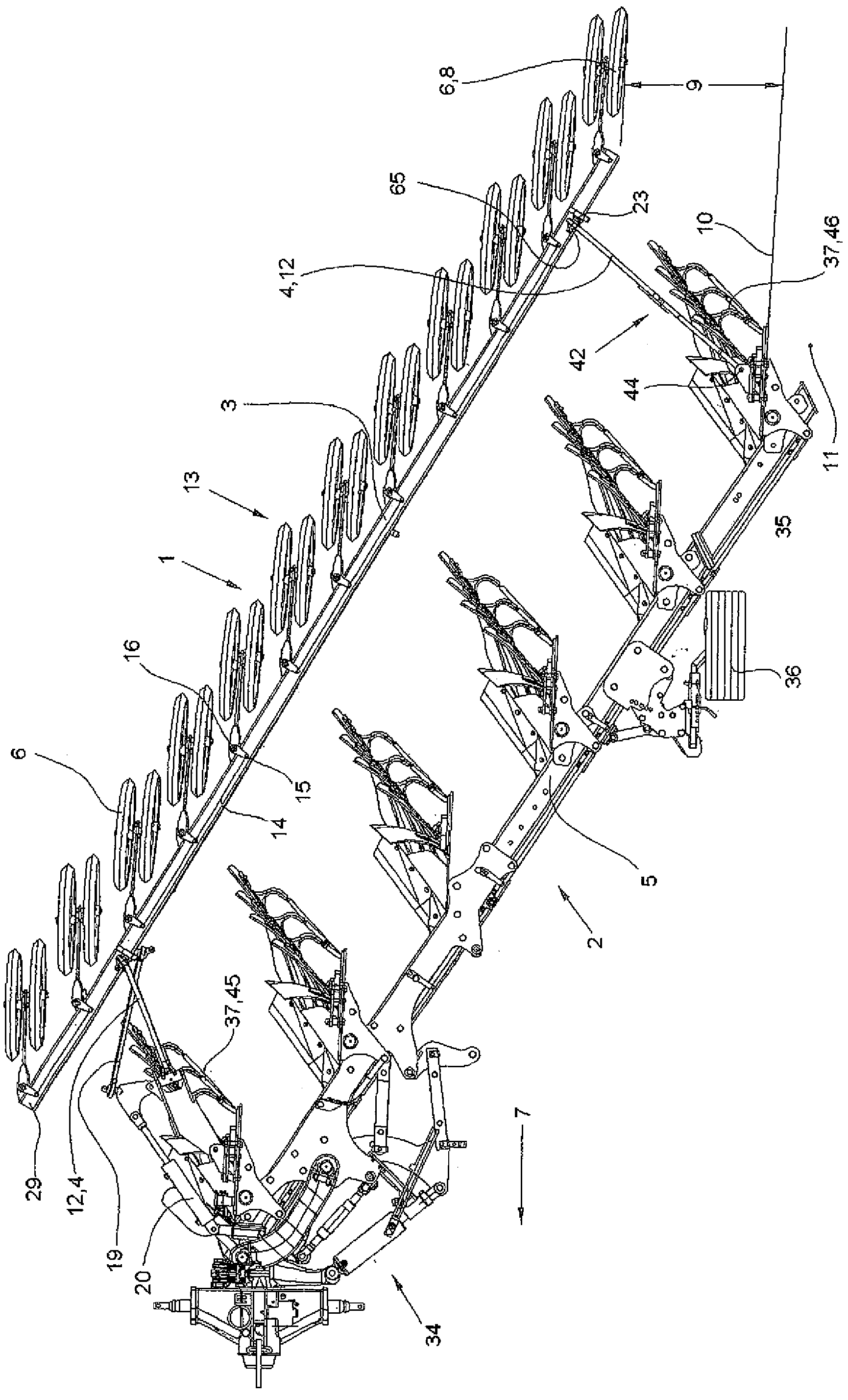

[0011] figure 1 Shown is a reversing plow 2 which, with its plow turret 30, can be connected via articulation points 31, 32 and 33 to a three-point tie rod (not shown) of a tractor and which has support wheels in the rear area 35 36. The tilting plow 2 has a link drive 34 with which in particular the front furrow width and the point of application of the tension can be adjusted and the plow frame 5 swiveled inwards, although this is not discussed further below in the description of the figures. The tilting plow 2 also has a plow frame 5 , to which the plow body 37 is fixed indirectly via a pivot bracket 40 and which can be adjusted in its working width about an axis of rotation 39 . The adjustment of the working width of the plow body 37 and thus the working width of the entire tilting plow 2 is effected by means of the hydraulic cylinder 38 . Here, the pivot brackets 40 of the individual plow bodies 37 are connected to one another via control rods 41 . Pivot bearings 44 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com