High-altitude deformable spark receiving device

A fire cloth and strip-shaped technology, which is applied in the field of high-altitude deformable fire contact devices, can solve the problems of low spark receiving rate, potential safety hazards, and low safety, so as to improve the safety factor, increase the fire contact surface, and save labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

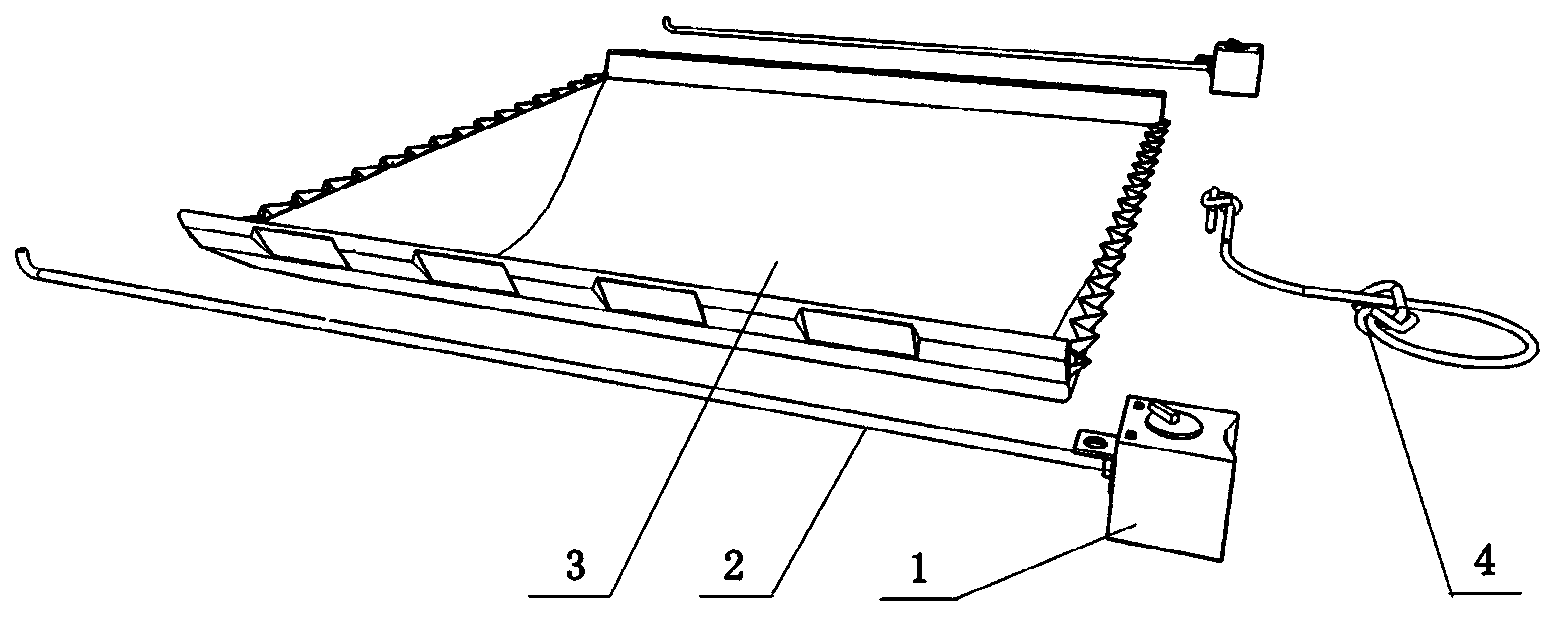

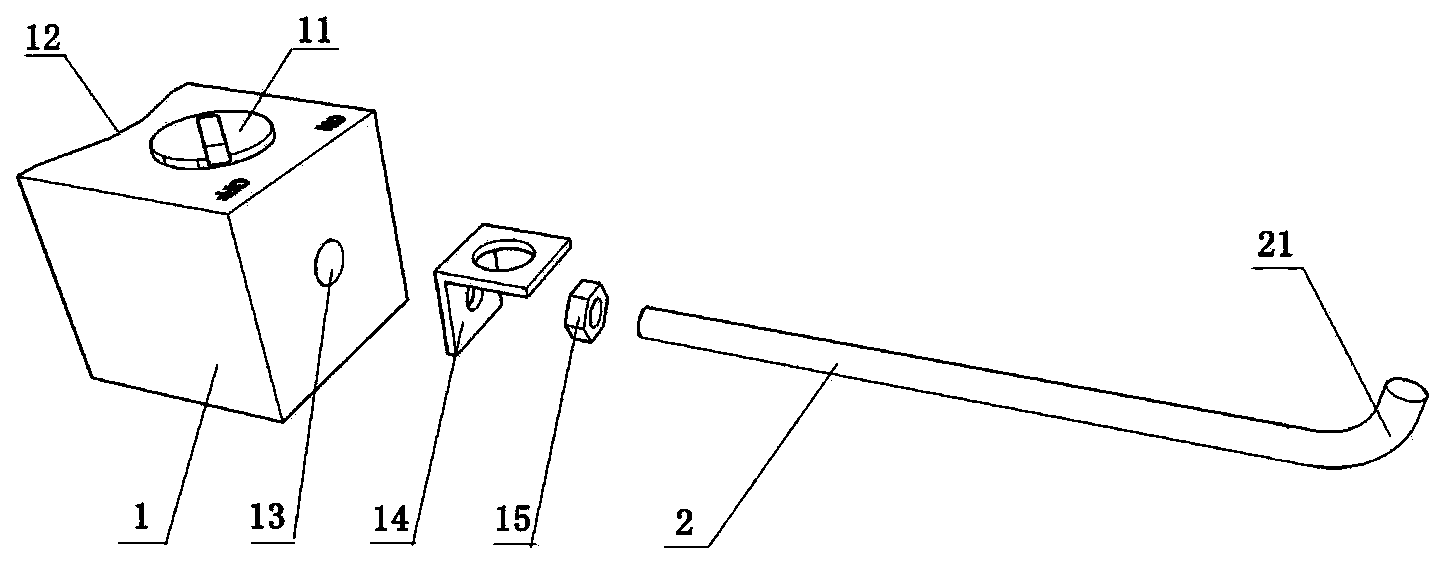

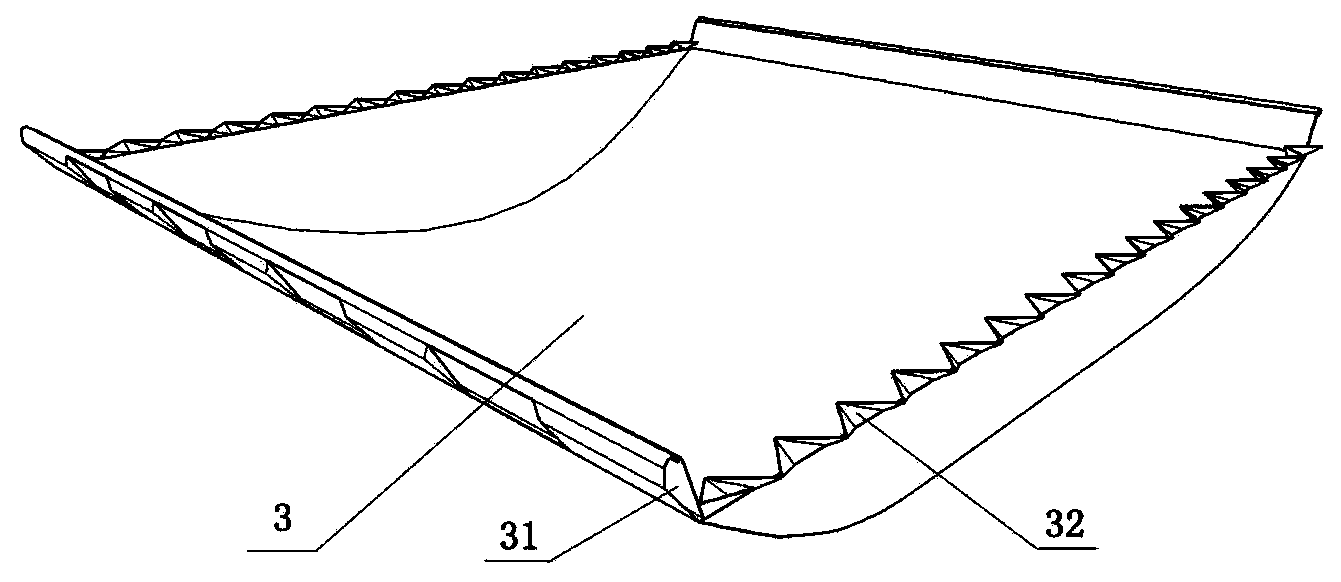

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention includes two magnetic bases 1, two metal rods 2, a fire cloth 3, an anti-fall safety belt, and two angle steels 14, and is characterized in that: one end of each metal rod 2 is fixed to a magnetic In the side threaded hole 13 of the seat 1, and each metal rod 2 passes through the elongated hole 31 formed by turning down one side of the fire cloth 3, and is connected with the fire cloth 3 as a whole; the two magnetic bases 1 are magnetically Be fixed on the steel structure; both sides of every piece of angle steel 14 are provided with holes, and every piece of angle steel 14 is fixed on the magnetic base 1 by a nut 15 and metal rod 2, and the two ends of the anti-fall safety belt 4 are respectively provided with hooks (41 , 43), two hooks are hung on the holes of two angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com