Method for calibrating camber angle and caster angle of wheel

A technology of wheel camber and caster, which is applied to vehicle components, transportation and packaging, steering mechanisms, etc., and can solve problems such as long adjustment time, poor accuracy, and complicated adjustment methods of front and rear camshafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

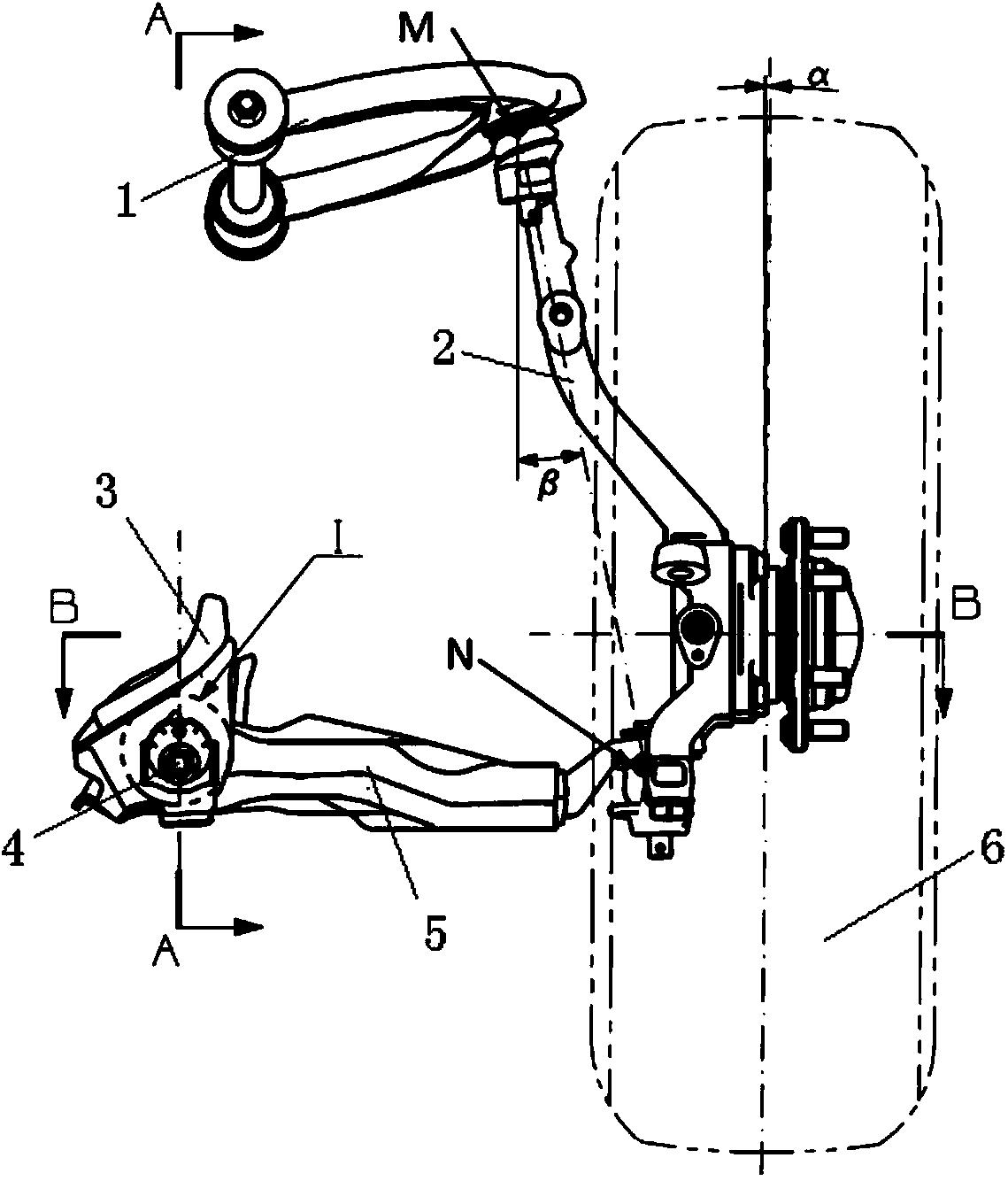

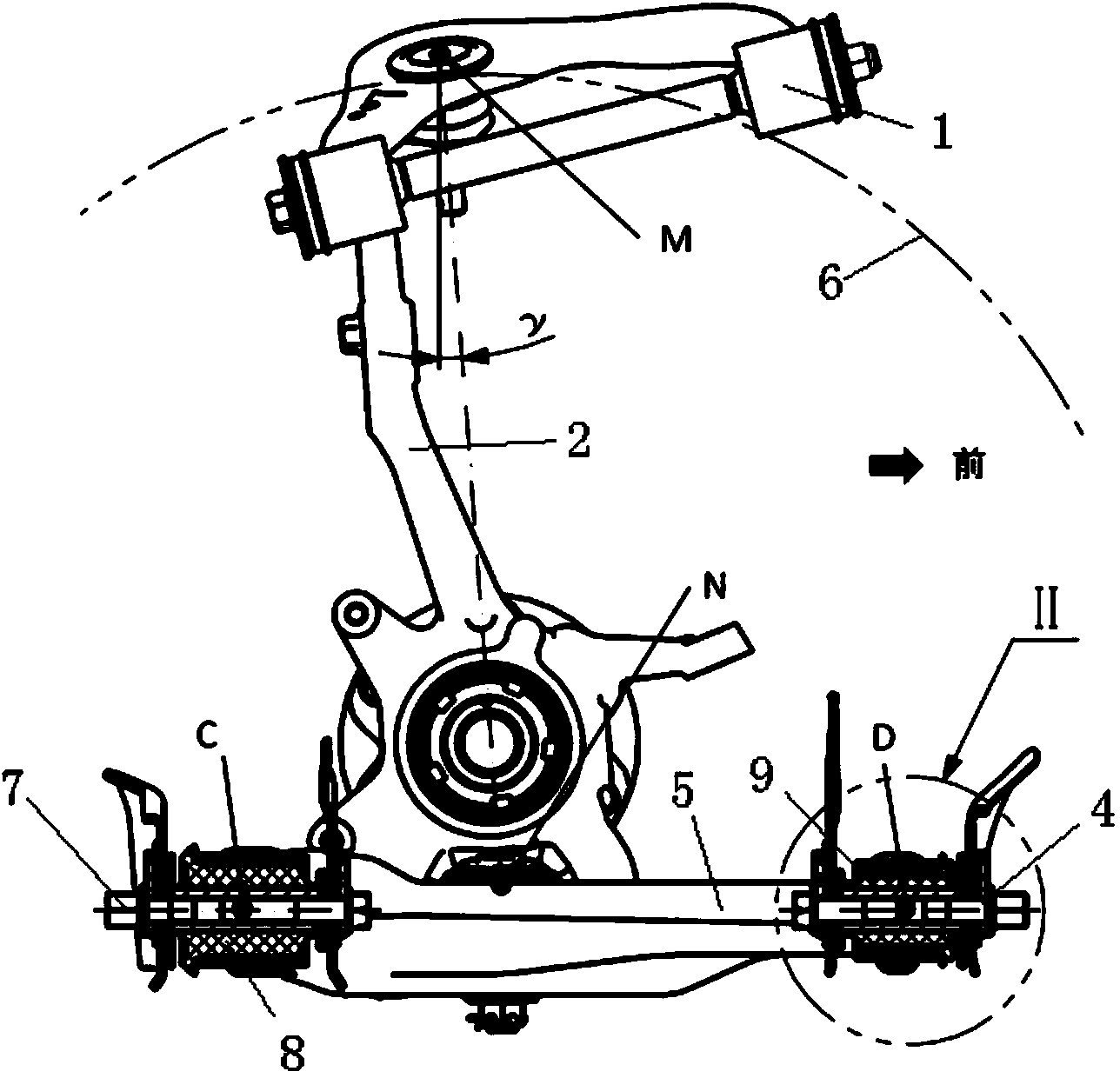

[0051] Embodiments of the present invention are described in detail below, and the described embodiments are illustrated in the drawings, wherein like or similar reference numerals designate like or similar elements throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0052] In the present embodiment, the front and the rear are aimed at the forward direction of the vehicle; the up and down are relative concepts; Match is OK.

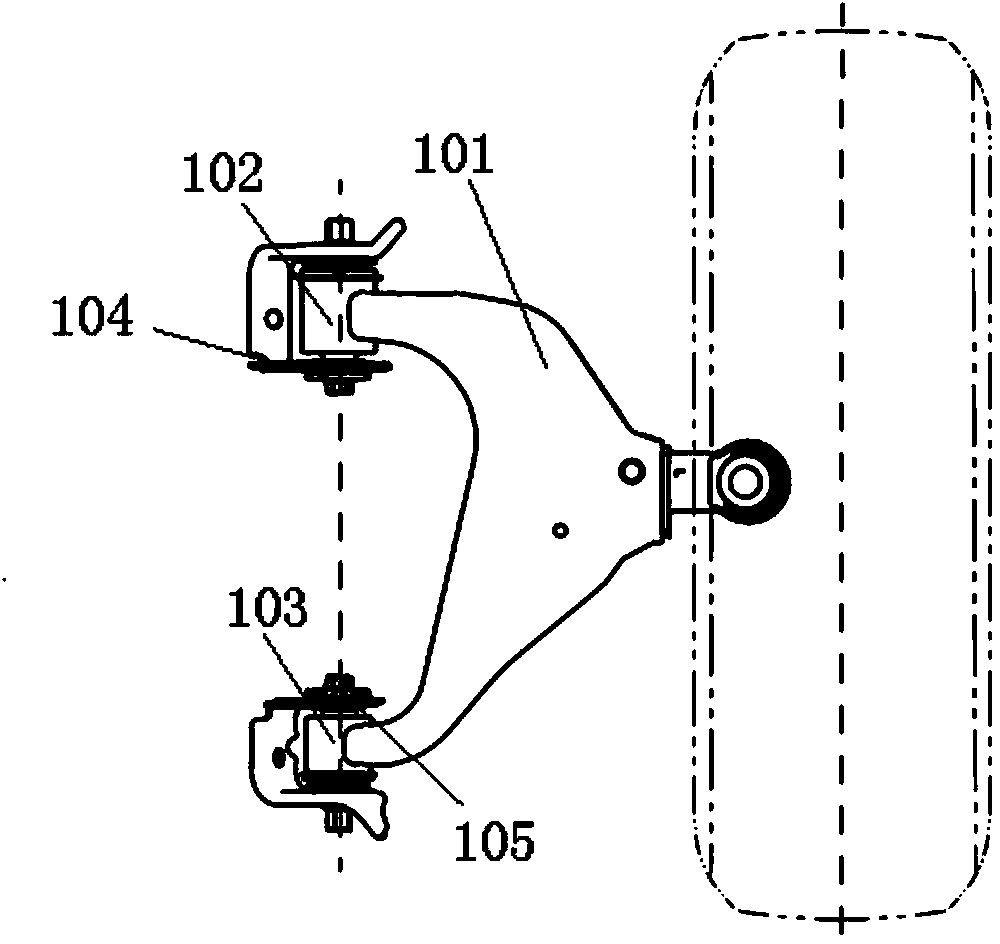

[0053] The present invention is applicable to all independent suspensions with two front and rear sleeves on the lower swing arm. In the present invention, the structure and material of the independent suspension are the same as the traditional materials, and the left and right of the independent suspension are symmetrical. The double wishbone independent suspension is used below The right side is used as an example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com