Novel belt clamping mechanism for belt conveyor

A belt conveyor and a new type of technology are applied in the field of entraining mechanisms for new belt conveyors, which can solve the problems of slow response speed, cumbersome maintenance work, complicated connecting pipelines, etc., and achieve simple operation, convenient later maintenance and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

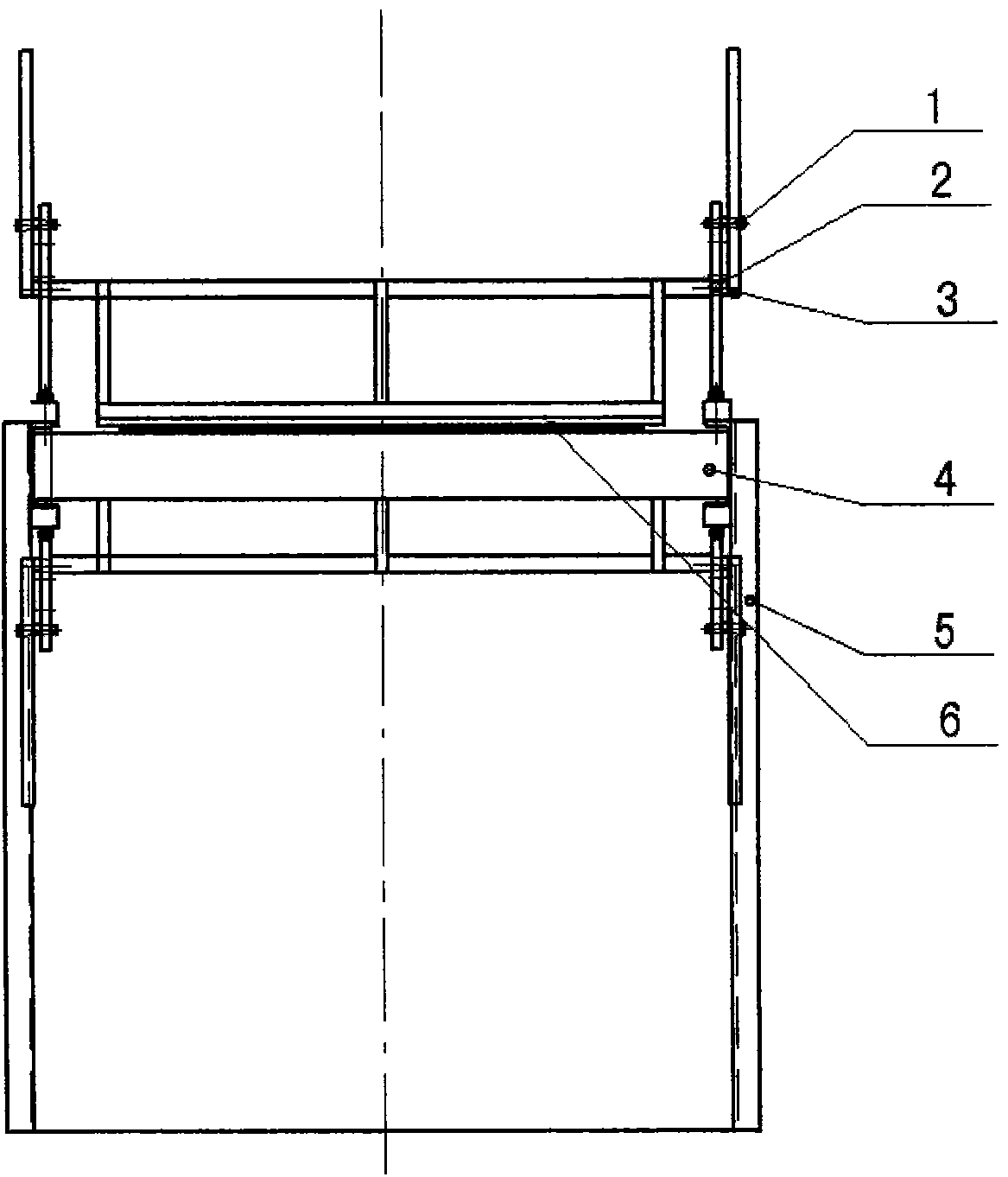

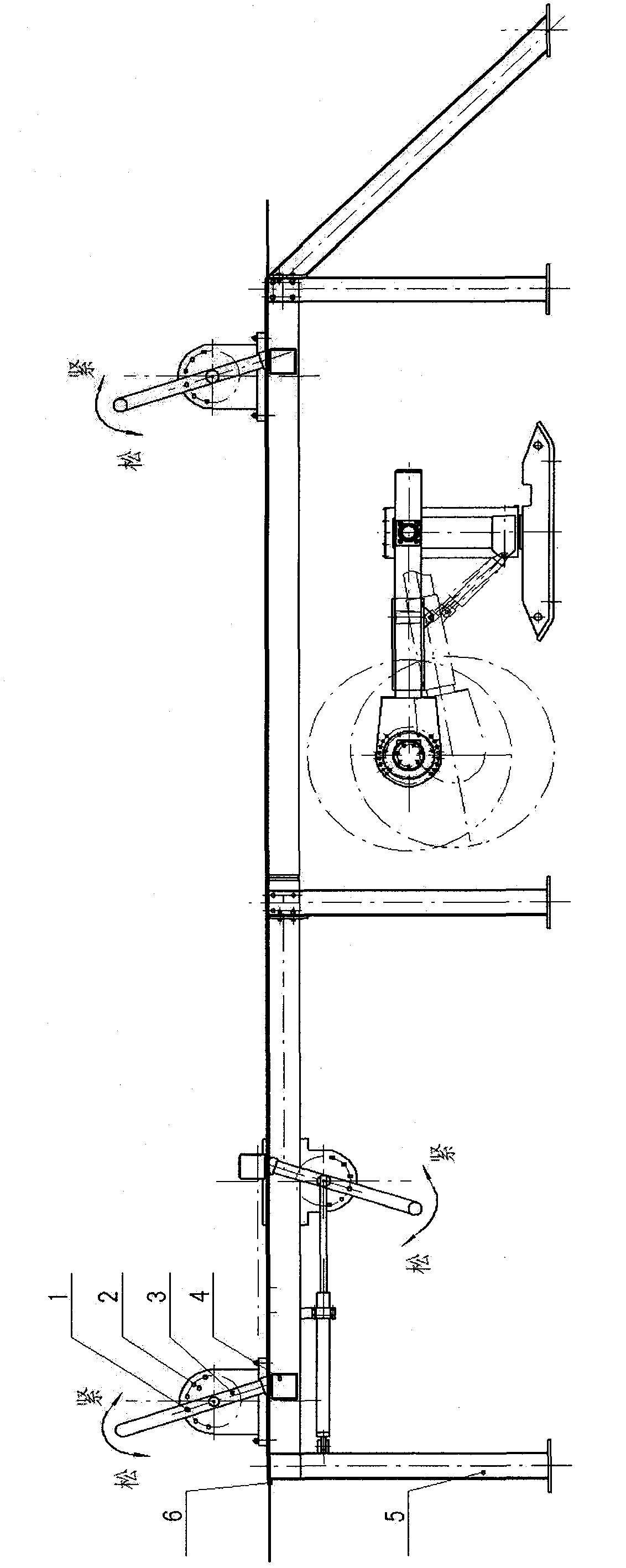

[0010] Such as Figure 1~2 As shown, the entrainment mechanism for the new belt conveyor is composed of a positioning pin 1, a hinge seat 2, an entrainment arm 3, a fixed beam 4, and a frame 5.

[0011] In actual use, first, the entrainment mechanism of the new type belt conveyor is equipped with a hinged seat 2 and a fixed beam 4 on the frame 5, and an entrainment arm 3 is installed on the hinged seat 2, and the conveyor belt of the belt conveyor is fixed on the entrainment arm 3 and Run between beams 4. Secondly, according to the actual situation, the distance between the entrainment beam and the fixed beam 4 is adjusted by swinging the entrainment arm 3 to clamp and loosen the conveyor belt 6 . In addition, when the position of the entraining arm 3 is determined, the positioning pin 1 can be inserted into the holes on the entraining arm 3 and the hinge seat 2 to fix the entraining arm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com