A scissor lift traveling mechanism for secondary lifting

A traveling mechanism and lift technology, which is applied to mechanical conveyors, conveyors, lifting frames, etc., can solve the problems of inconvenient portability and installation, high requirements, etc., and achieve the effect of simple structure, easy manufacture and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

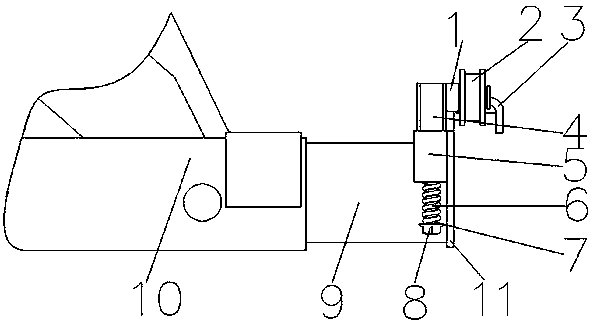

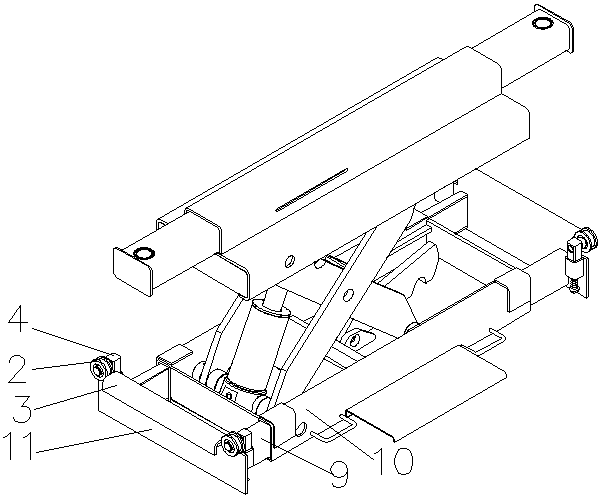

[0018] Such as figure 1 with figure 2 As shown, a scissor lift traveling mechanism for secondary lifting includes a fixed base plate 10, a movable base plate 9, a vertical plate 11, a short hanging plate 3 and a roller mechanism, and one end of the movable base plate 9 is sleeved on the In the fixed bottom plate 10, one end of the movable bottom plate is sleeved in the fixed bottom plate to realize the adjustability of the length of the bottom plate, which is applicable to lifting vehicles of different widths. The vertical plate 11 is rectangular, and is vertically arranged on the other end surface of the movable base plate 9, and the side of the vertical plate 11 top facing away from the movable base plate 9 is also fixed with a short hanging plate 3, and the vertical plate 11 is fixed on the side of the movable base plate 9. The cross-section of the combination of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com