Air impermeability detecting table for sluice valve

An air-tightness detection and gate valve technology, which is applied in the use of liquid/vacuum for liquid-tightness measurement, and by detecting the appearance of fluid at the leak point, etc., which can solve the problem of valve body crushing, inconvenient use of jaws, and valve body quality. Influence and other problems, to achieve the effect of reliable pressing, avoiding uneven clamping and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

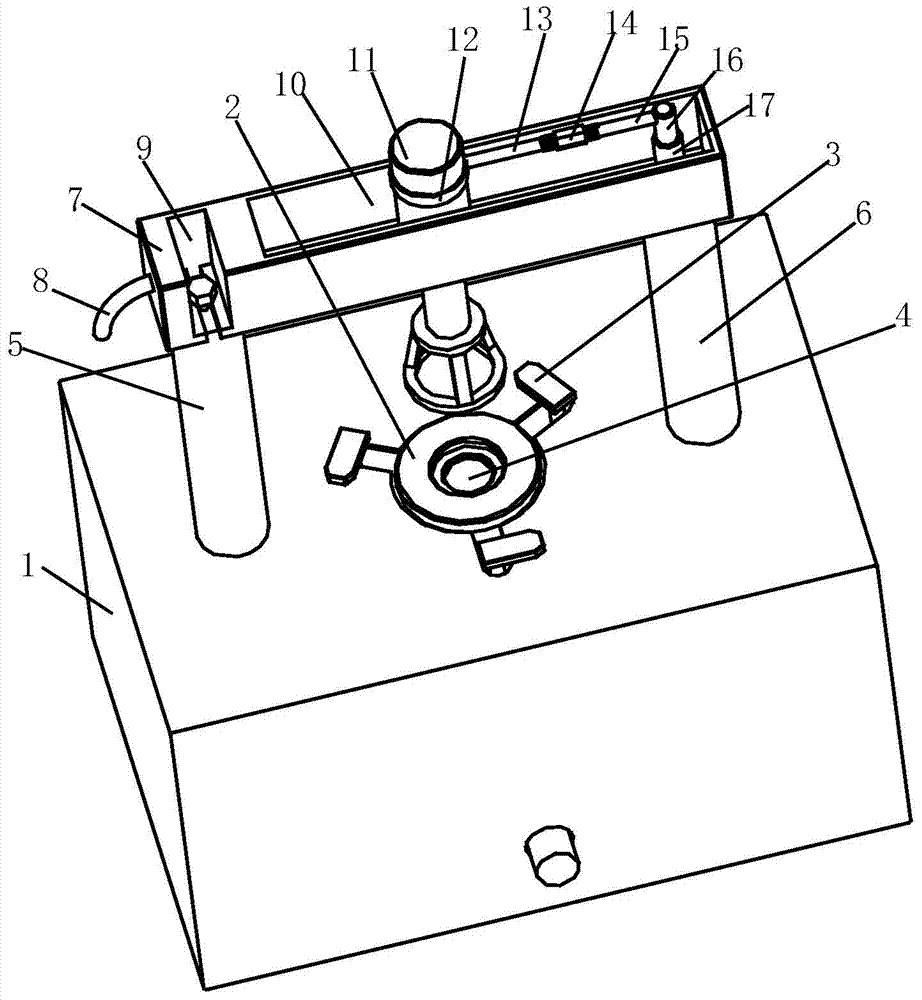

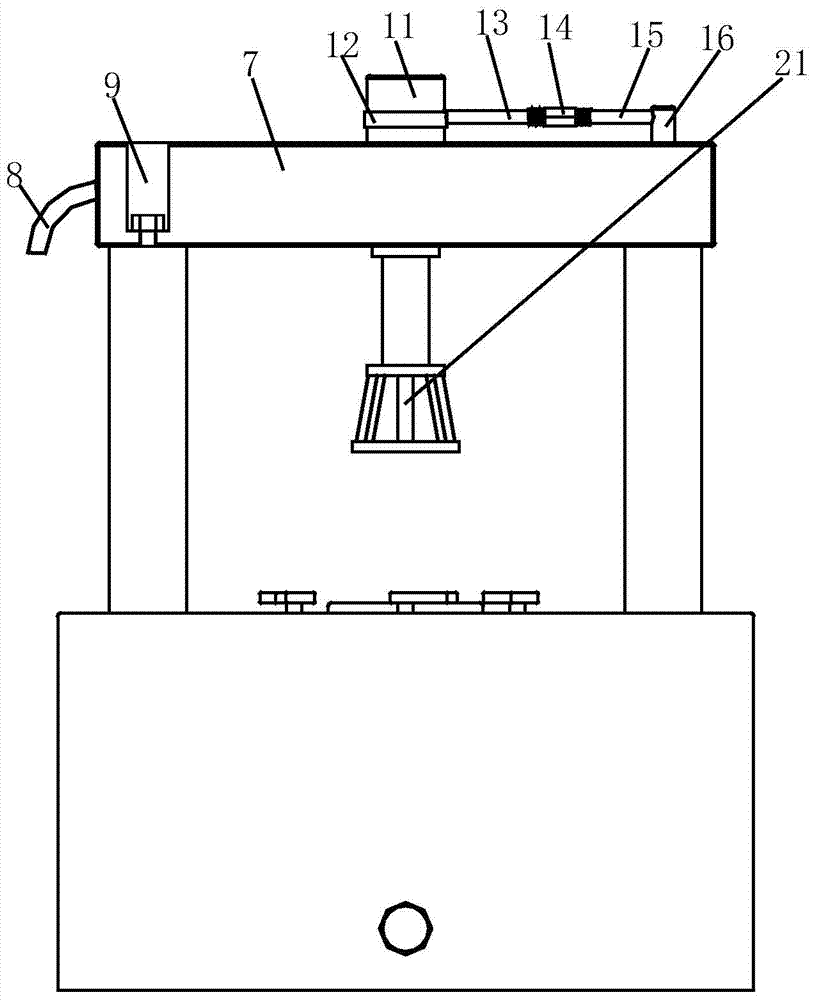

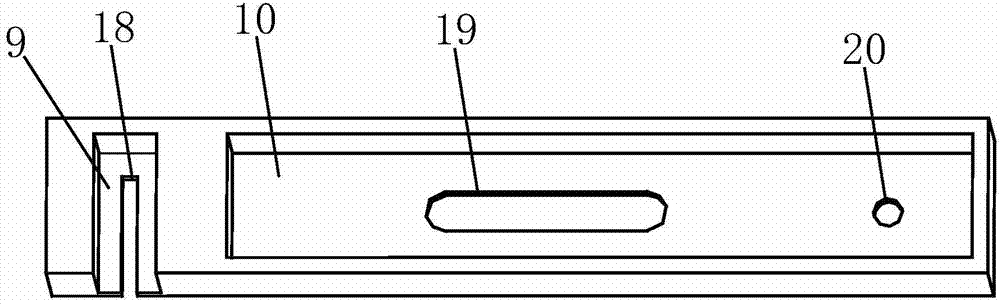

[0015] Such as Figure 1 to Figure 4 As shown, a gate valve air tightness testing platform includes a clamping platform 1, a sealing platform 2 is provided in the middle of the upper end surface of the clamping platform 1, an air supply hole 4 is provided in the center of the sealing platform 2, and the surrounding of the sealing platform 2 is uniform There are claws 3 for fixing and pressing the valve body. The left and right sides of the upper end surface of the clamping platform 1 are respectively provided with a left support column 5 and a right support column 6. A movable clamping column is provided above the clamping platform 1. frame 7, the right part of the upper end surface of the movable compression frame 7 is provided with a groove 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com