Culturing method and large rotary culturing equipment

A culture method and equipment technology, applied in the field of aquaculture methods and giant slewing aquaculture equipment, can solve the problems of single function, easy hypoxia of aquatic animals, etc., and achieve the effect of expanding the oxygen-enhancing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

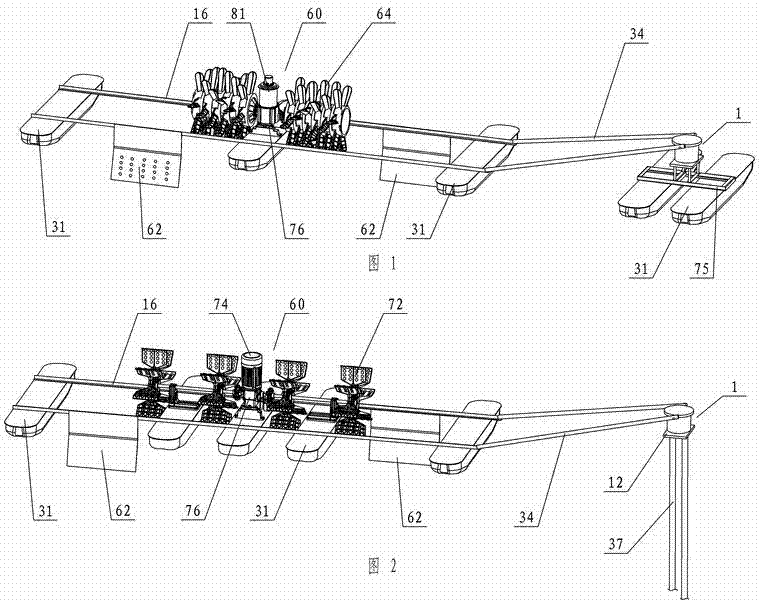

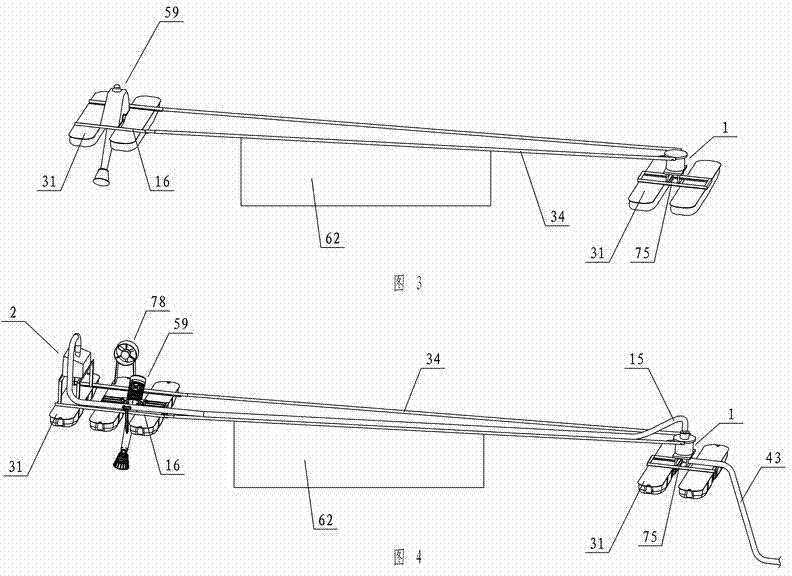

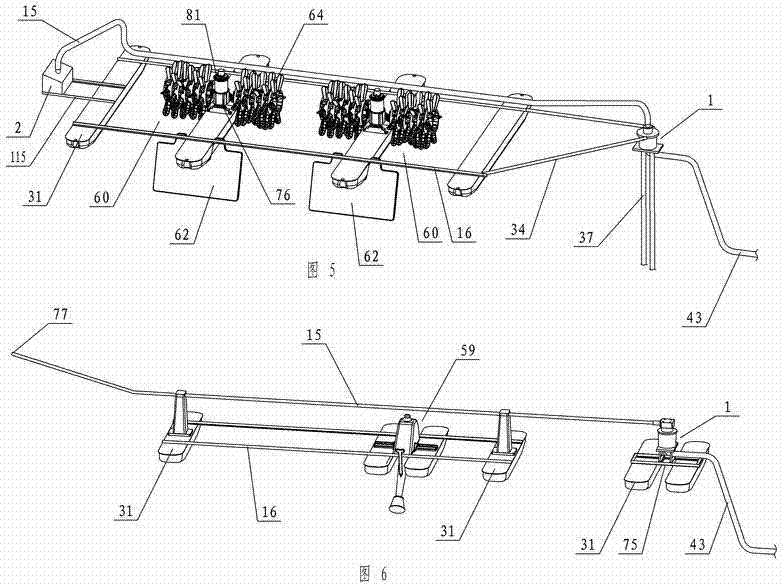

[0054] Embodiment 1: A kind of large-turn breeding equipment, mainly including water uniform blade 62, floating body, slewing arm, aeration mechanism, conversion mechanism 1, described conversion mechanism 1 is fixed in the middle of the feeding area on the water surface of the breeding waters, the fixing method Yes: a vertical pile 37 is set at the bottom of the water, the central axis 6 of the conversion mechanism 1 is fixed on the lower flange 12, and the lower flange 12 is fixed on the vertical pile 37, and the vertical pile 37 is preferably reinforced concrete. Pile driving is inconvenient and can be fixed by floating body, and conversion mechanism 1 is floated on the water surface location, and the lower flange 12 of conversion mechanism can be fixed on the floating body, or be fixed on the floating body by shelf 75. Stakes or floating bodies become the positioning mechanism of the present invention. Described rotary arm comprises connecting rod 34, support 16, and the l...

Embodiment 2

[0058]Embodiment 2: On the basis of the above-mentioned embodiment 1, it also includes a conversion mechanism 1, a feeding mechanism, and a blast mechanism; the feeding mechanism includes a material storage container 19 and a feeder, and the feeding mechanism has a material delivery duct 43 is connected to the feed pipe joint 11 of the conversion mechanism, and one end of the discharge pipe 15 is connected to the rotor of the conversion mechanism, and the aerator and the discharge pipe 15 rotate around the conversion mechanism 1 together; Feed air pipe 43 is blown in the discharge pipe 15 and throws in the fish pond by the feed that divides out in the material storage container 19 by feeder. The length of the slewing arm and the number of floating boats 31 can be set according to the radius of rotation. The connecting rod 34 is connected with the rotor of the conversion mechanism. The material radius and blanking width are set, and a plurality of material outlets 77 can be set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com