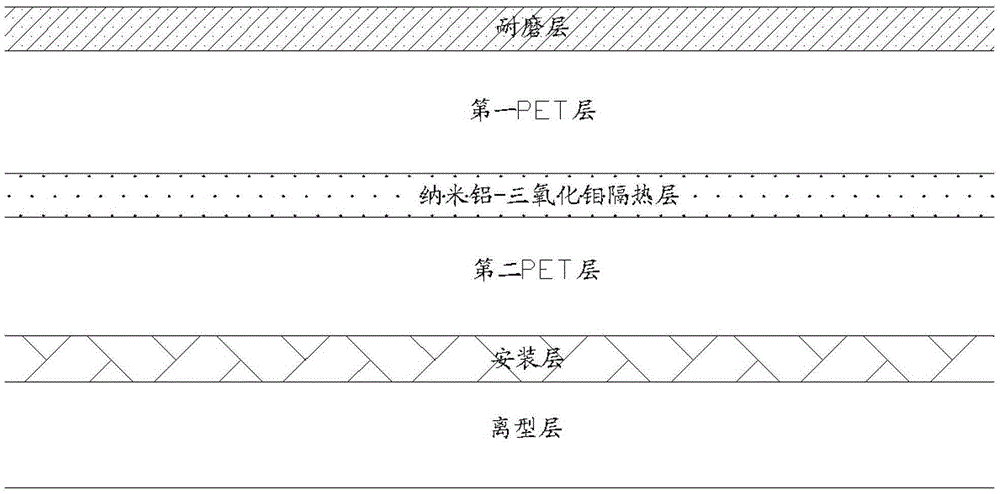

High-performance nano-aluminum-molybdenum trioxide composite thermal insulation film and preparation method thereof

A technology of nano-molybdenum trioxide and molybdenum trioxide, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, coatings, etc., which can solve the problems of high production energy consumption, high maintenance cost of evaporation equipment, weakened heat insulation effect, etc. problem, to achieve high reflective heat insulation performance, low production cost, and reduce the effect of secondary radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Add 1.5kg of aluminum powder with a diameter of less than 75um, 40kg of steel balls with a diameter of less than 2mm, 5kg of MIBK, 300g of PVP, and 300g of stearic acid into the planetary ball mill, fill it with nitrogen protection, and grind at 300rpm for 50h to prepare nano-aluminum powder slurry;

[0035] 2) Add 4.5kg of nano-molybdenum trioxide powder, 120kg of steel balls with a diameter of less than 2mm, 700g of PVP, and 800g of OP-10 into 15kg of MIBK, and use a planetary ball mill to grind for 1 hour to prepare nano-molybdenum trioxide slurry;

[0036] 3) Weigh 4.5kg of nano-aluminum slurry and 11.5kg of nano-molybdenum trioxide slurry, add them to 20kg of ethyl acetate and stir for 20min respectively, add 20kg of polyacrylate resin PS-60, add 100g of ultraviolet light absorber UV -9, stir and disperse for 1 hour, and prepare nano-aluminum-molybdenum trioxide heat-insulating adhesive by filtering with a 1500-mesh membrane pump;

[0037] 4) Roll-coat the above...

Embodiment 2

[0045] 1) Add 1.0kg of aluminum powder with a diameter of less than 75um, 27kg of steel balls with a diameter of less than 2mm, 3.3kg of MIBK, 200g of PVP, and 200g of lauric acid into the planetary ball mill, fill it with nitrogen protection, and grind at 300rpm for 100h to prepare nano-aluminum slurry;

[0046] 2) Add 3.0kg of nano-molybdenum trioxide powder, 80kg of steel balls with a diameter of less than 2mm, 600g of PVP, and 400g of OP-10 into 10kg of MIBK, and use a planetary ball mill to grind for 1 hour to prepare nano-molybdenum trioxide slurry;

[0047] 3) Weigh 3.0kg of nano-aluminum slurry and 7.6kg of nano-molybdenum trioxide slurry, add them to 20kg of toluene in turn and stir for 20 minutes respectively, add 13.5kg of polyacrylate resin PS-60, add 70g of ultraviolet light absorber UV- 531, stir and disperse for 1 hour, and use a 1500-mesh membrane pump to filter to prepare nano-aluminum-molybdenum trioxide heat-insulating glue;

[0048] 4) Roll-coat the above-m...

Embodiment 3

[0056] 1) Add 1.5g of aluminum powder with a diameter of less than 75um, 4g of steel balls with a diameter of less than 2mm, 5g of MIBK, 300mg of PVP, and 300mg of stearic acid into a planetary ball mill, fill it with nitrogen protection, and grind at 300rpm for 50h to prepare nano-aluminum slurry;

[0057] 2) Add 1g of nano-molybdenum trioxide powder, 3.5g of steel balls with a diameter of less than 2mm, 150mg of PVP, and 120mg of SDS into 3g of MIBK, and use a ball mill to grind for 1 hour to prepare nano-molybdenum trioxide slurry;

[0058] 3) Weigh 1.2g of nano-aluminum slurry and 1.8g of nano-molybdenum trioxide slurry, add them to 4g of butyl acetate in turn, stir magnetically for 20min respectively, add 3g of polyacrylate resin PS-60, 100mg of ultraviolet light absorber UV -327, magnetic stirring for 30 minutes, using a mortar to grind for 5 minutes to prepare nano-aluminum-molybdenum trioxide thermal insulation glue;

[0059] 4) Use a film applicator to apply the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com