Thermal insulation coating composition as well as preparation method and application thereof

A technology for thermal insulation coatings and compositions, applied in cellulose coatings, reflective/signal coatings, coatings, etc., can solve the problems of difficult production of coatings, general thermal insulation performance, and first use, etc., to achieve stable composition and improve reflection isolation. The effect of thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

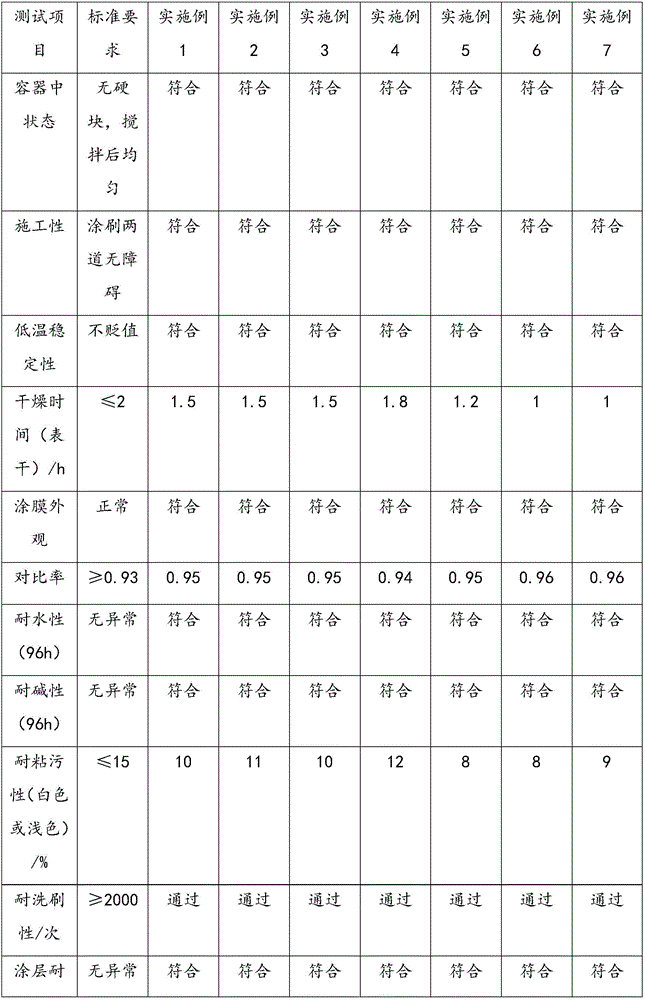

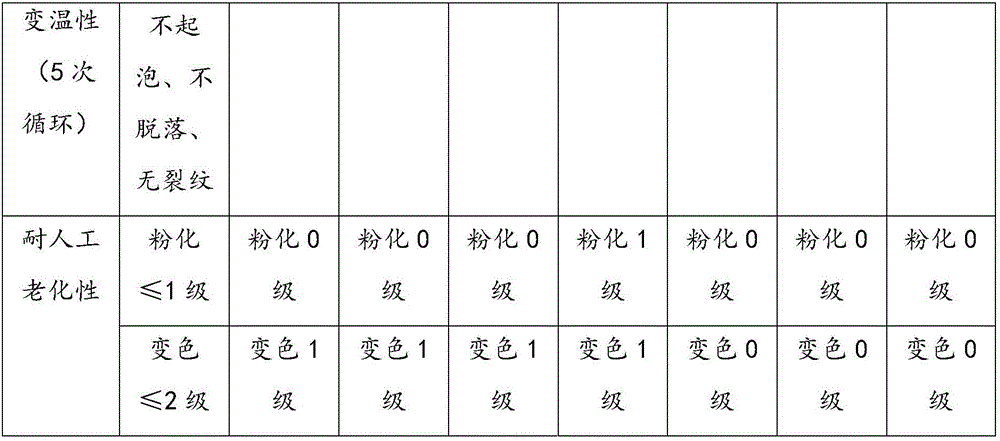

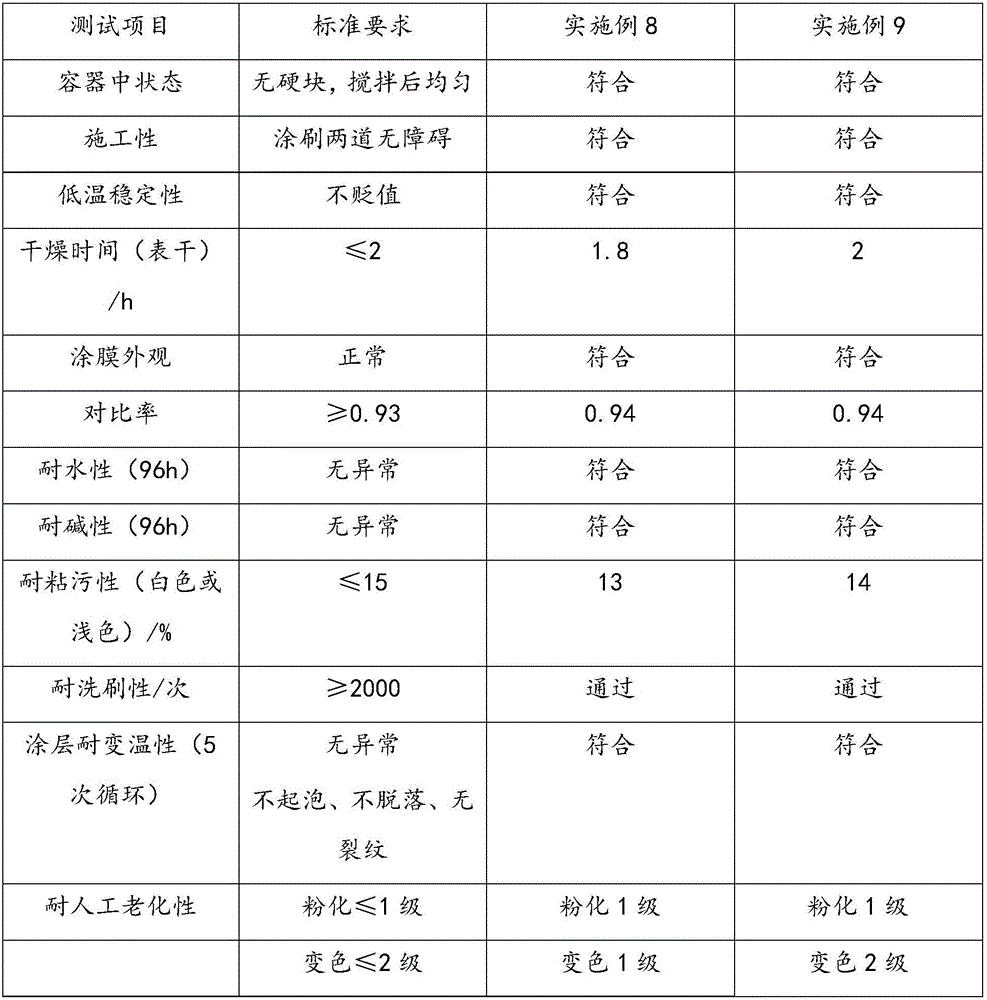

Examples

Embodiment 1

[0037] According to parts by weight, 25 parts of pure water, 2 parts of ethylene glycol, 15 parts of cellulose, 10 parts of barium sulfate, 10 parts of kaolin, 10 parts of titanium dioxide, 15 parts of heat insulation powder and 30 parts of styrene-acrylic emulsion were weighed Appropriate amount of raw materials for each component;

[0038] Wherein, the kaolin is calcined kaolin, and the titanium dioxide is rutile titanium dioxide;

[0039] Wherein, the heat-insulating powder is a mixture of nano-alumina and nano-silicon dioxide, and the mass ratio of nano-alumina to nano-silicon dioxide is 3:2.

[0040] Then, after mixing water, cellulose and ethylene glycol; then, add barium sulfate, kaolin and titanium dioxide, and continue mixing; finally, add styrene-acrylic emulsion and heat insulation powder and continue stirring to obtain the heat insulation material of Example 1. coating composition.

Embodiment 2

[0042] According to parts by weight, 30 parts of pure water, 2 parts of ethylene glycol, 20 parts of cellulose, 5 parts of barium sulfate, 20 parts of kaolin, 15 parts of titanium dioxide, 20 parts of heat insulation powder and 20 parts of styrene-acrylic emulsion were weighed Appropriate amount of raw materials for each component;

[0043] Wherein, the kaolin is calcined kaolin, and the titanium dioxide is rutile titanium dioxide;

[0044]Wherein, the heat-insulating powder is a mixture of nano-vanadium dioxide and nano-silicon dioxide, and the mass ratio of nano-vanadium dioxide to nano-silicon dioxide is 3:5.

[0045] Then, after mixing water, cellulose and ethylene glycol; then, add barium sulfate, kaolin and titanium dioxide, and continue mixing; finally, add styrene-acrylic emulsion and heat insulation powder and continue stirring to obtain the heat insulation material of Example 2. coating composition.

Embodiment 3

[0047] According to parts by weight, 25 parts of pure water, 2 parts of ethylene glycol, 15 parts of cellulose, 5 parts of barium sulfate, 20 parts of kaolin, 15 parts of titanium dioxide, 15 parts of heat insulating powder and 20 parts of styrene-acrylic emulsion were weighed Appropriate amount of raw materials for each component;

[0048] Wherein, the kaolin is calcined kaolin, and the titanium dioxide is rutile titanium dioxide;

[0049] Wherein, the heat-insulating powder is a mixture of nano-vanadium dioxide and nano-alumina, and the mass ratio of nano-vanadium dioxide to nano-alumina is 3:5.

[0050] Then, after mixing water, cellulose and ethylene glycol; then, add barium sulfate, kaolin and titanium dioxide, and continue mixing; finally, add styrene-acrylic emulsion and heat insulation powder and continue stirring to obtain the heat insulation material of Example 3. coating composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com