Tire

A tire and tire circumferential technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve problems such as uneven wear and achieve the effect of suppressing uneven wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

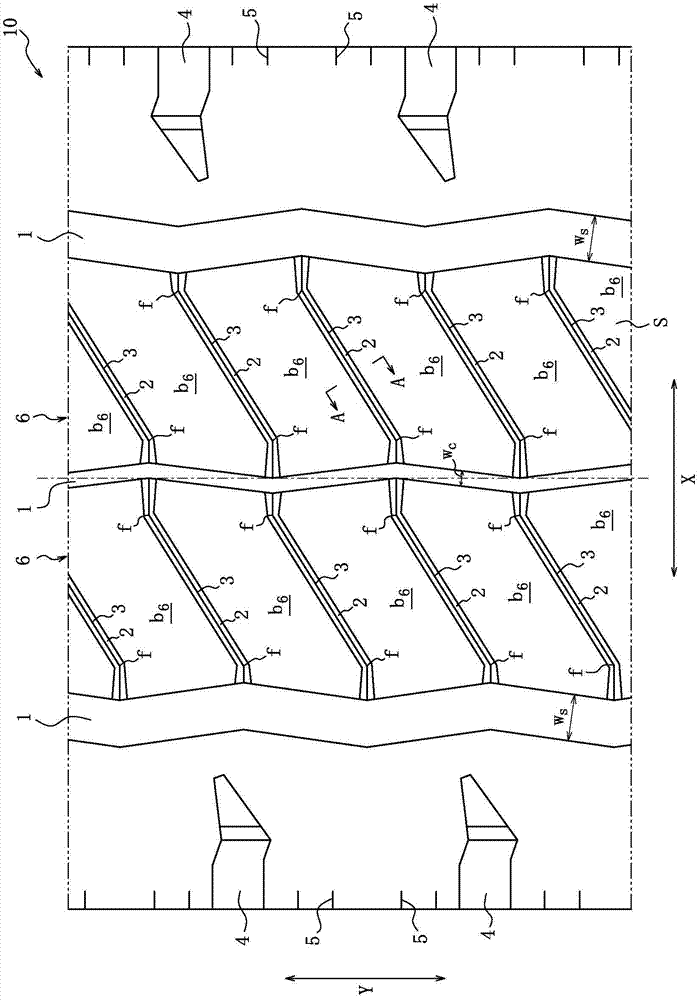

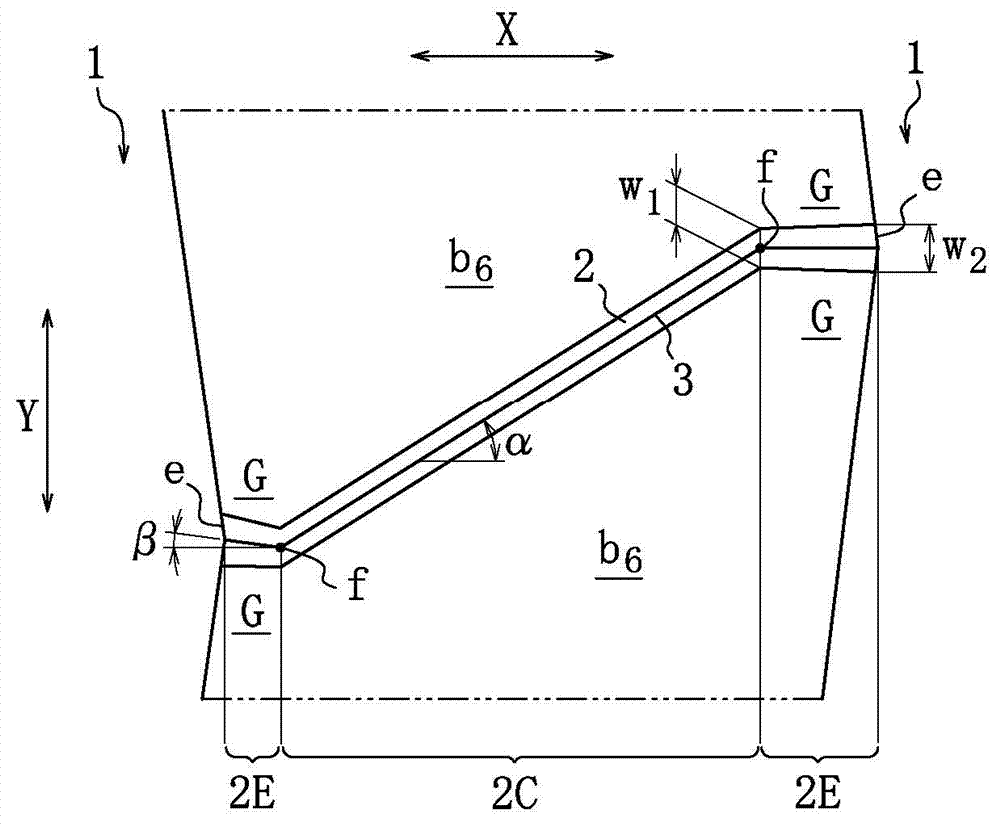

[0023] Below, while referring to the attached Figure 1 The tire of the present invention will be described in detail by taking an embodiment of the tire of the present invention as an example. figure 1 It is a partially developed view showing the tread contact surface S of the tire 10 according to the embodiment of the present invention. In addition, although illustration is omitted, this tire 10 includes: a carcass spanning between a pair of bead portions and composed of carcass layers of organic fiber cords or steel cords; the radially outer side of the tire, consisting of layers of steel cords; and the tread.

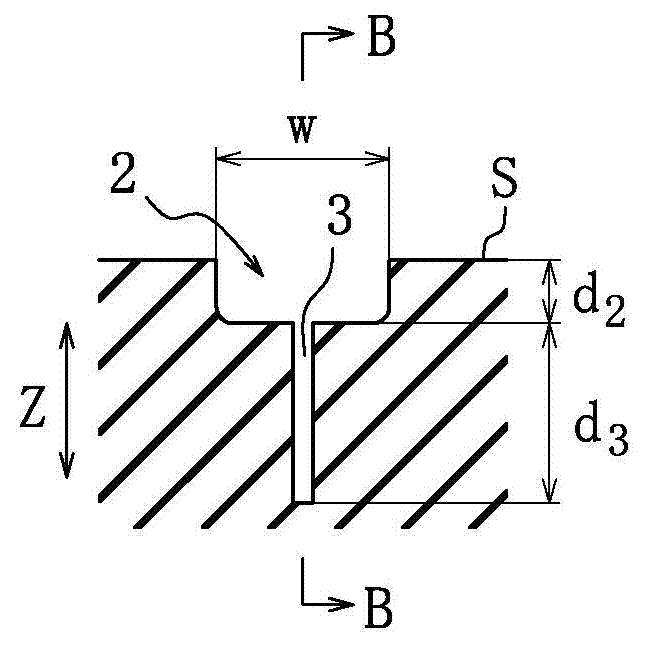

[0024] On the tread contact surface S of the tire 10, using the tire circumferential direction ( figure 1 A plurality of circumferential grooves 1 (three in the illustrated example) extending in the Y direction) divide two land portions 6, and a plurality of land portions 6 are arranged on the two land portions 6 respectively. The transverse grooves 2 extend obli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com