Full automatic glue film packing machine

A packaging machine, fully automatic technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of stainless steel terminal slipping damage, reduce product qualification rate and production efficiency, etc., to achieve low production cost, simple structure, simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

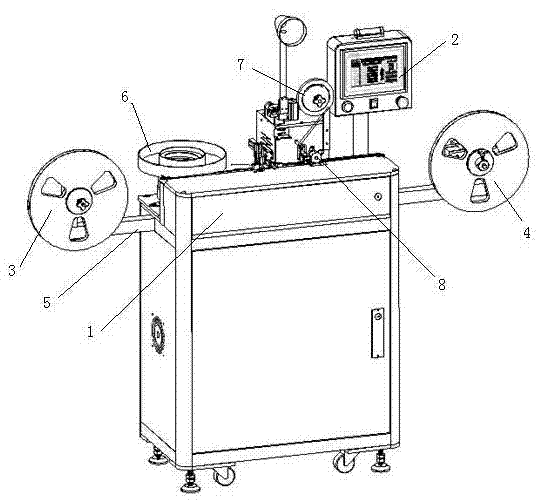

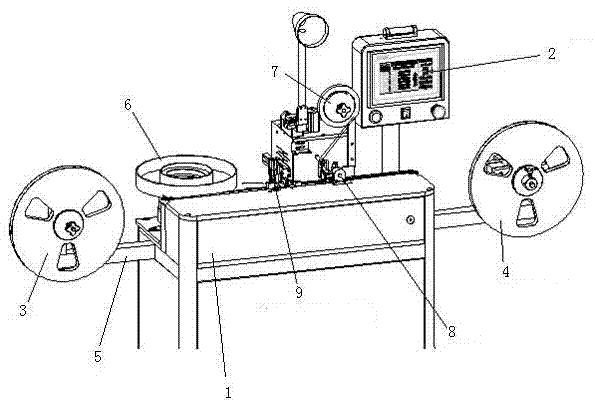

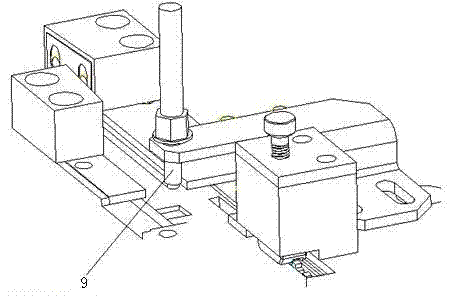

[0021] further as Figure 1 to Figure 4 As shown, first place the carrier tape on the unloading tape reel 3 and lead it to the tape reel guide rail 5, pass through the positioning induction wheel (not shown in the figure) and the pressing feed wheel 8 to connect to the receiving tape reel 4, then place the stainless steel clip terminals in the vibrating plate 6, put the film on the film positioning wheel 7 and introduce the pressure feeding wheel 8, the vibrating plate 6 will arrange the stainless steel clip terminals in the correct direction and advance the material track and send it to the bottom of the stainless steel clip terminal jaw 10, and then set the total quantity required for production through the computer control component 2 and then start the machine (when there is a lack of material, the machine will stop and display the lack of material on the man-machine interface, please manually Refilling, in order to quickly eliminate the situation and continue production),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com