Stretchable packaging box bottom structure

A bottom structure and packaging box technology, which is applied in packaging, food packaging, transportation and packaging, etc., can solve the problems of inconvenient production and high cost, and achieve the effects of convenient production, reduced usage, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

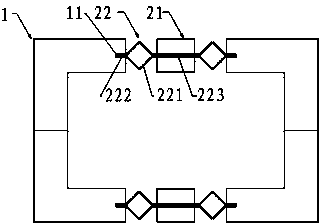

[0039] refer to figure 1 As shown, a retractable packing box bottom structure, the bottom structure is a rectangular structure composed of pads 1 and connectors 2, the pads 1 are located at the four corners of the rectangular structure, there are four pads 1, each Each spacer 1 is L-shaped, and one end of the L-shaped spacer 1 is connected to a connecting piece 2, that is, a connecting piece 2 is arranged between two spacers 1 in the length direction of the rectangular structure. The spacer 1 mainly plays the role of buffering and supporting, and the connector 2 can be stretched according to the bottom size of the packaged product so as to change the size in the length direction.

[0040] Such as figure 1 , Figures 5-1 to 5-3 As shown, the connecting piece 2 includes a foam piece 21 and a diamond-shaped piece 22 on each side of the foam piece 21. The first slot 11 is provided at the end of the pad 1 connected to the connecting piece 2. The diamond-shaped piece 22 includes a...

Embodiment 2

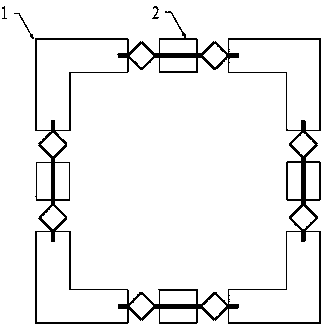

[0047] refer to figure 2 The bottom structure of the telescopic packing box shown is different from Embodiment 1 in that connectors 2 are also arranged between the pads 1 in the width direction of the rectangular structure, and the structure of the connectors 2 is the same as in Embodiment 1. The pads The structure of 1 differs from that of embodiment 1 in that first slots 11 are provided at both ends to facilitate connection with the connector 2, so that the bottom structure can be stretched in both length and width directions. Others are the same as in Embodiment 1, and will not be repeated.

Embodiment 3

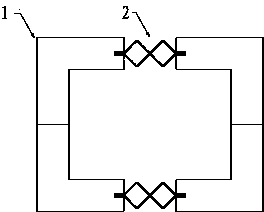

[0049] refer to image 3 The difference between the bottom structure of the telescopic packing box shown in Embodiment 1 is that the structural form of the connector 2 is different, and the connector 2 is two connecting units consisting of only two diamond-shaped parts 22 without foam parts 21 .

[0050] Such as Figure 7-1 , 7-2 As shown, when the connector 2 includes two connecting units, the connector 2 is made of two pieces of corrugated paper c, d, the middle of each piece of corrugated paper is provided with an insertion slot 224, and the two sides of the insertion slot 224 are respectively provided with front cutting lines e and the back knife line f, two pieces of corrugated paper c, d are folded along the knife line and then plugged together, and the two pieces of corrugated paper c, d are bonded and fixed at their two ends to form the first connecting part 222 to facilitate the connection with the spacer 1 The upper first slot 11 is plugged and fitted.

[0051] Of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com