Tongue-and-groove formwork that can be spliced quickly and prevents mistakes

A rapid splicing and formwork technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of poor concrete appearance, long docking time, and low efficacy, so as to improve the appearance quality of concrete, speed up on-site installation, and improve concrete quality. The effect of staggered control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following non-limiting examples illustrate the invention.

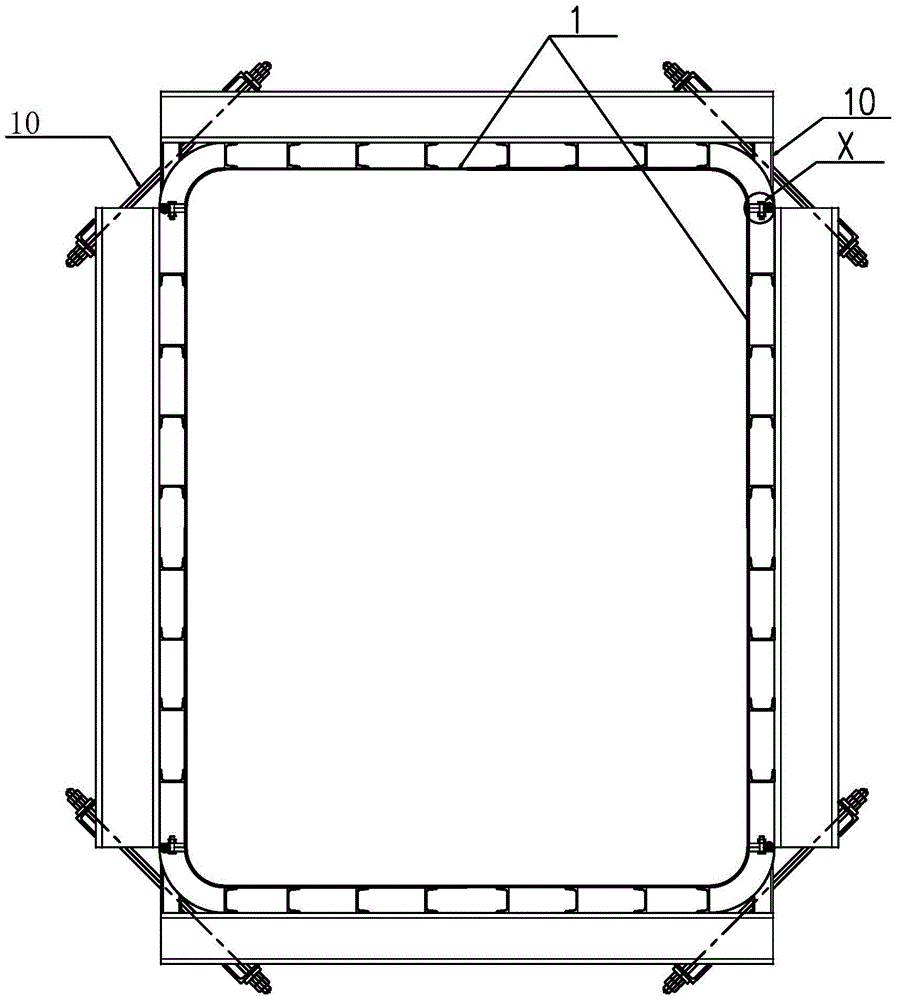

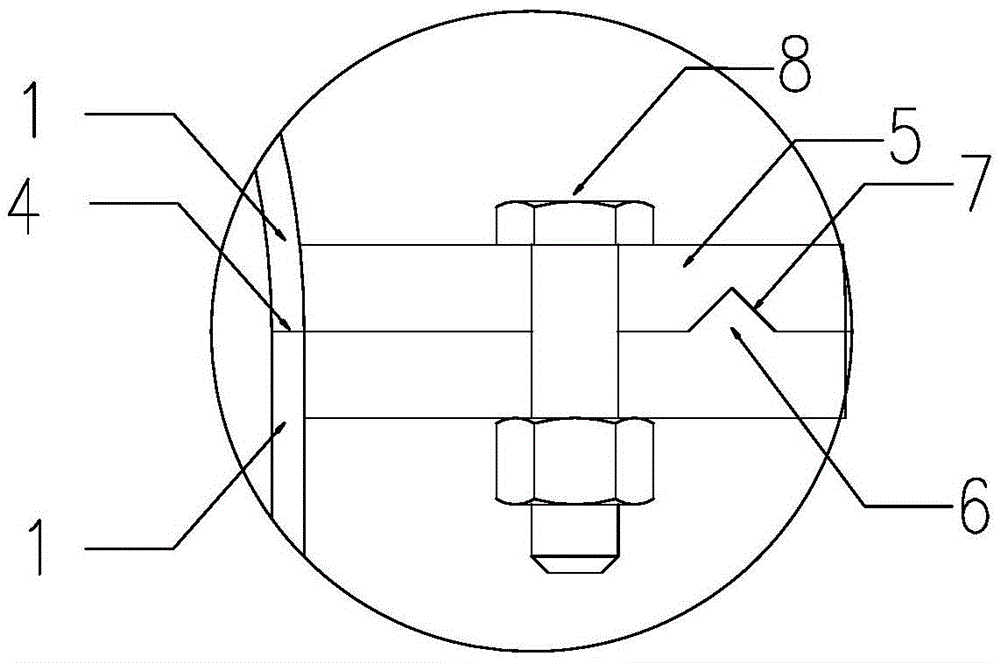

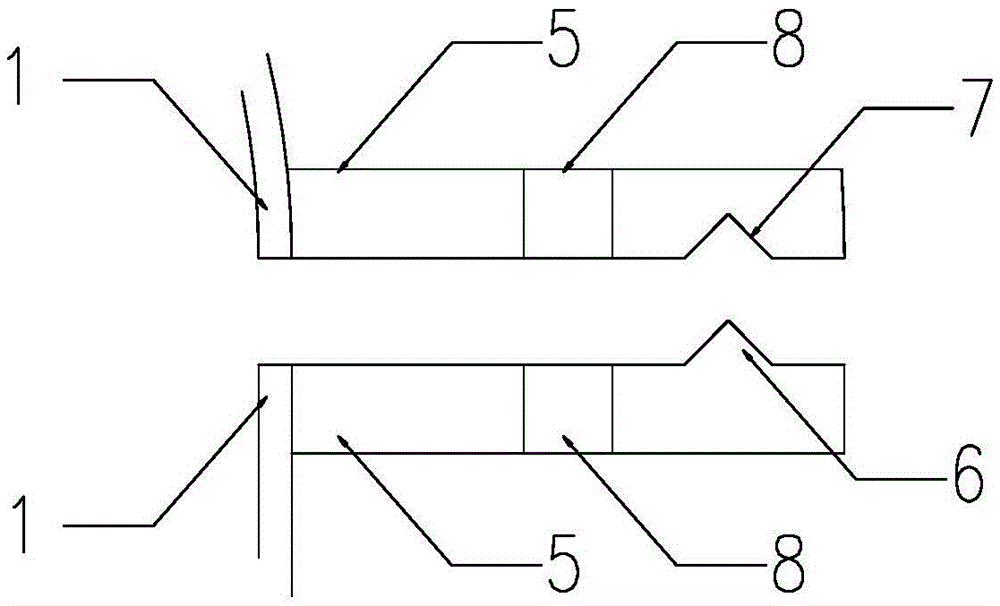

[0034] refer to Figure 1-10 As shown, a tongue-and-groove formwork that can be spliced quickly and prevents mistakes, includes a pier formwork formed by splicing a plurality of formwork panels 1, and the outer wall of the formwork panel 1 is also provided with vertical ribs 2 and horizontal ribs. Small ribs3. As in this example figure 1 As shown, four formwork panels 1 are spliced into a rounded rectangular shape. The joints 4 of the template panels 1 spliced in pairs are respectively provided with tenons 6 and tenon grooves 7 along the length direction, and the tenons 6 and tenon grooves 7 are matched and corresponding, and the butt joints 4 of the two spliced template panels 1 The flange sides 5 at the position are also fastened by three bolts 8 arranged at the head, tail and middle in the overall length direction, such as Figure 4 , 5 As shown, the outer periphery of the pier formwork is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com