Asymmetric Two-Piece Piezoelectric Fiber Inertial Drive Device

A piezoelectric fiber, inertial drive technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. It can overcome problems such as backward movement, and achieve the effect of overcoming difficult control, helping to store kinetic energy and increasing the movement stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

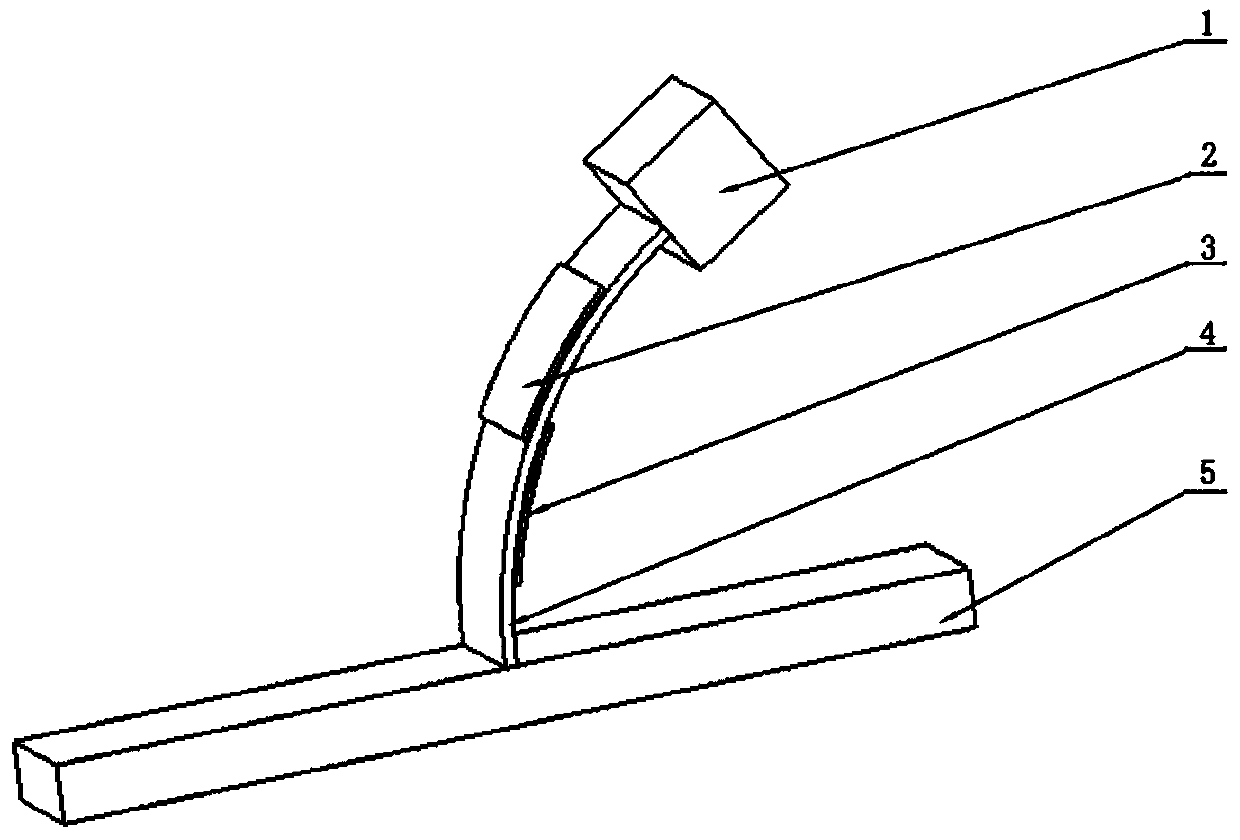

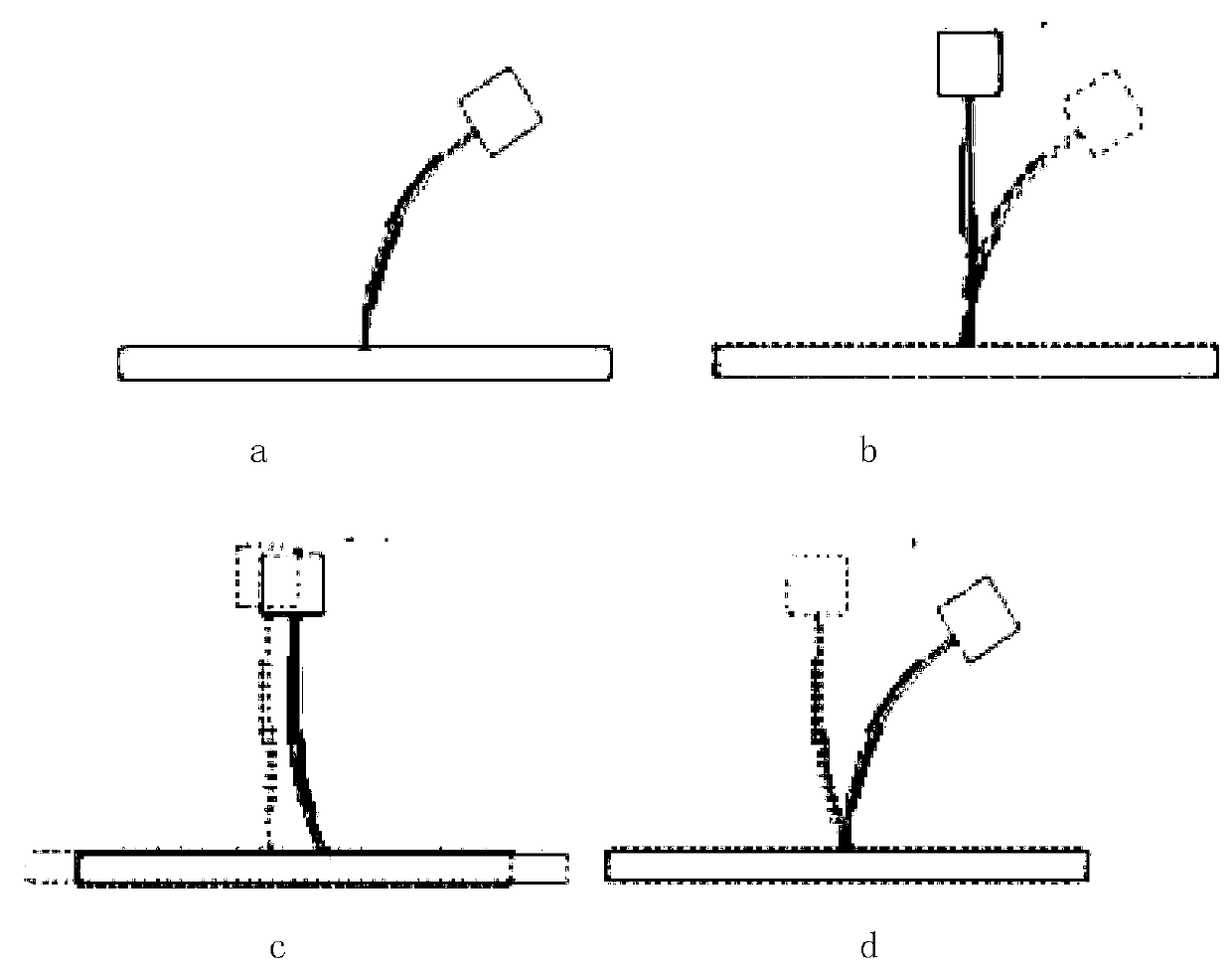

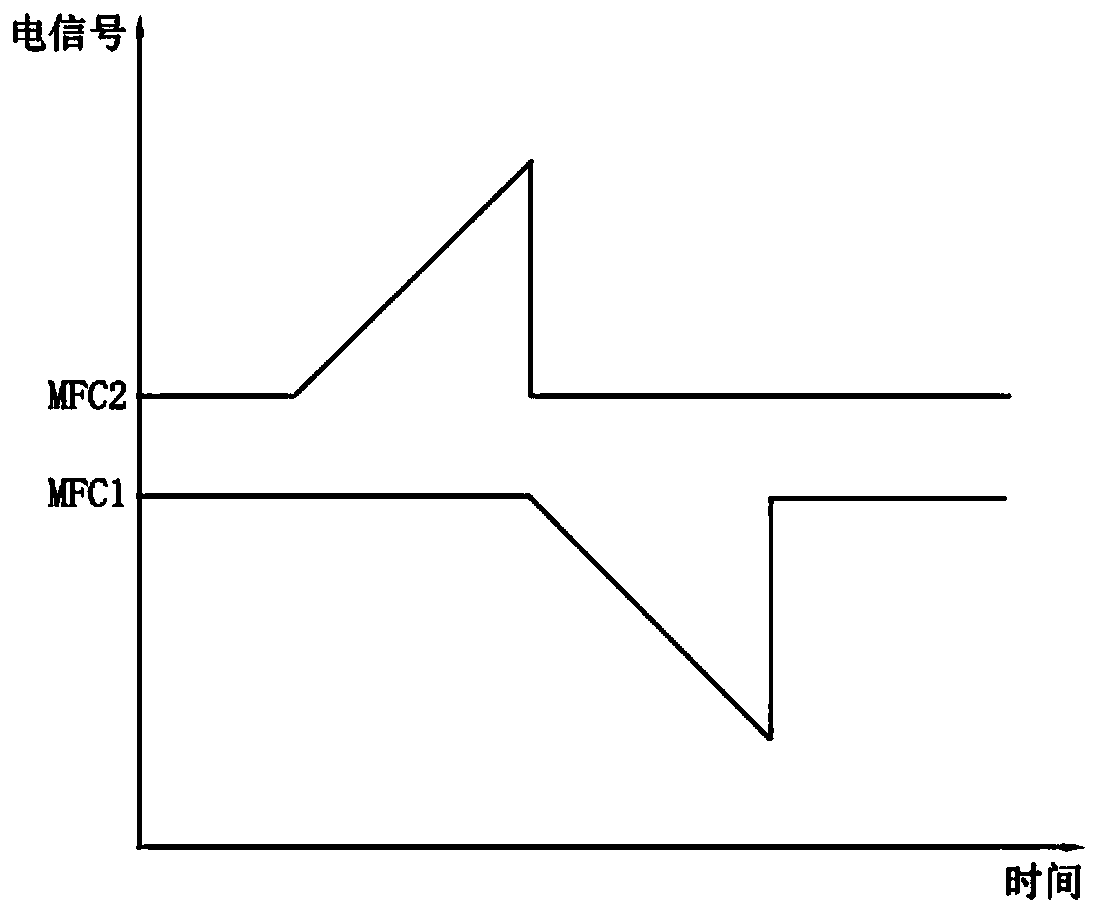

[0016] The invention relates to an asymmetric double-plate piezoelectric fiber inertial driving device, which is a new type of driving device which utilizes the inverse piezoelectric effect of the piezoelectric fiber and the inertial driving principle to drive the mechanism to realize motion. Such as figure 1 As shown, the actuator is composed of two pieces of piezoelectric fibers asymmetrically bonded on a metal substrate that is pre-bent to a certain radian, and the two ends of the metal plate (4) are connected to mass block 1 (1) and mass block 2 (5) , wherein the mass block 2 (5) plays a stabilizing and supporting role, and the mass block 1 (1) generates inertial force during the movement. The piezoelectric fiber 1 (2), the piezoelectric fiber 2 (3) and the metal plate (4) are bonded in parallel with conductive glue. The metal plate (4) is processed into a certain radian, and the end is processed into a threaded column so as to connect the mass block 1 (1) and the mass bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com