Production line fast feeding mechanism and working method with intelligent deceleration device

A feeding mechanism and production line technology, applied in the direction of shock absorbers, shock absorbers, mechanical equipment, etc., can solve problems such as inability to decelerate, material flying out, etc., achieve the effects of prolonging life, relieving intracavity pressure, and being applicable to a wide range of places

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

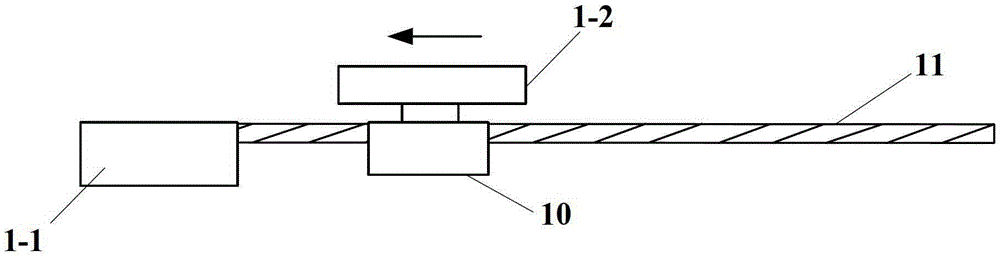

[0026] See figure 1 , one A production line feeding mechanism, comprising: a guide rail body 11, a slide block 10 that is slidably fitted on the guide rail body 11, and a material tray 1-2 is provided on the slide block 10; A speed reduction device 1-1 for deceleration.

[0027] The reduction gear 1-1 is a buffer.

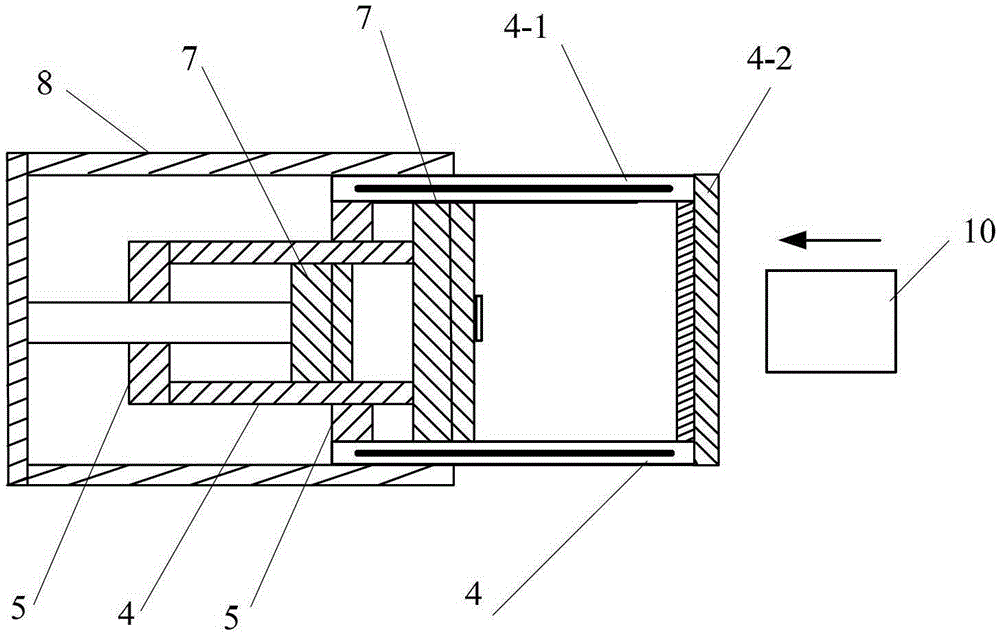

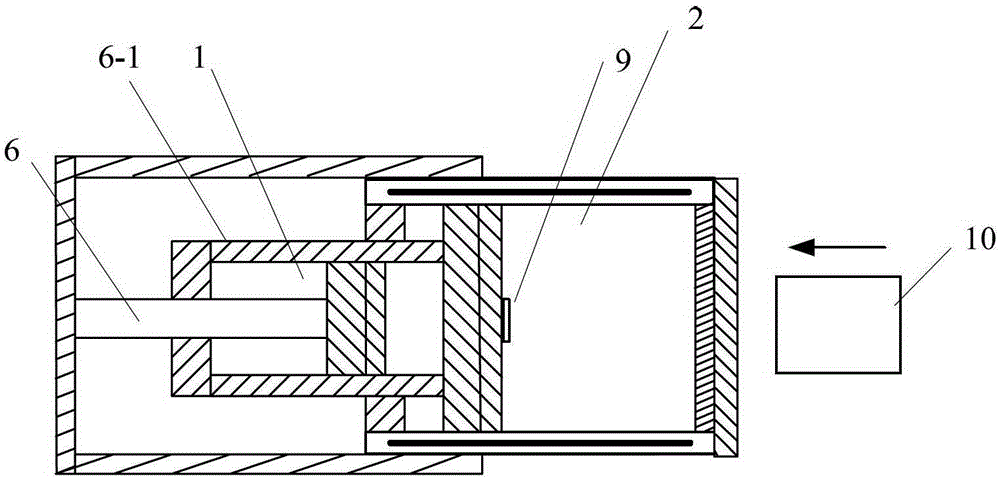

[0028] See figure 2 , image 3 and Figure 6, the buffer is a two-stage buffer, and the two-stage buffer includes: a first-stage buffer 1 and a final-stage buffer 2; the first-stage buffer 1 and the final-stage buffer 2 respectively include: cylindrical, And be used for filling the cylinder body 4 of cushioning medium, be provided with cylinder head 5 in the open end seal of this cylinder body 4, in the central through hole of described cylinder head 5, seal movable fit a piston rod 6, the right end of this piston rod 6 There is a piston body assembly 7 for adjusting the back-and-forth flow of the medium, the piston body assembly 7 is suitable for piston mo...

Embodiment 2

[0039] See figure 1 , figure 2 , image 3 and Figure 6 , a working method of a production line feeding mechanism based on the embodiments;

[0040] The feeding mechanism of the production line includes: a guide rail body 11, a slide block 10 slidingly fitted on the guide rail body 11, and a material tray 1-2 is arranged on the slide block 10; 10. A deceleration device 1-1 for decelerating.

[0041] The reduction gear 1-1 is a buffer, and the buffer is a two-stage buffer.

[0042] The two-stage buffer includes: a first-stage buffer 1 and a final-stage buffer 2; the first-stage buffer 1 and the last-stage buffer 2 respectively include: a cylinder 4 that is cylindrical and is used to fill a buffer medium A cylinder cover 5 is sealed at the open end of the cylinder body 4, and a piston rod 6 is fitted in the central through hole of the cylinder cover 5 for sealing and movable movement. The right end of the piston rod 6 is provided with a piston body for adjusting the back a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com